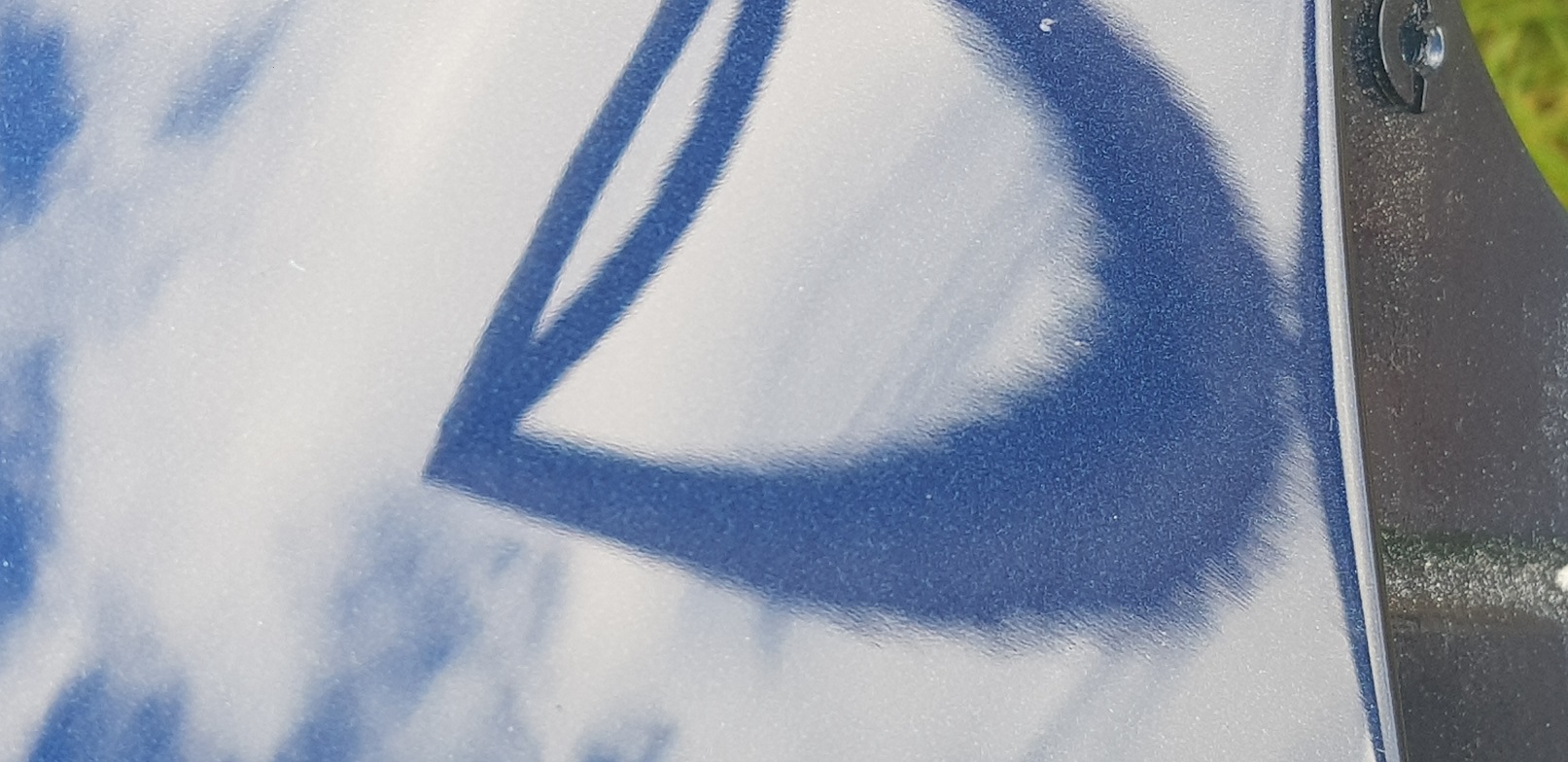

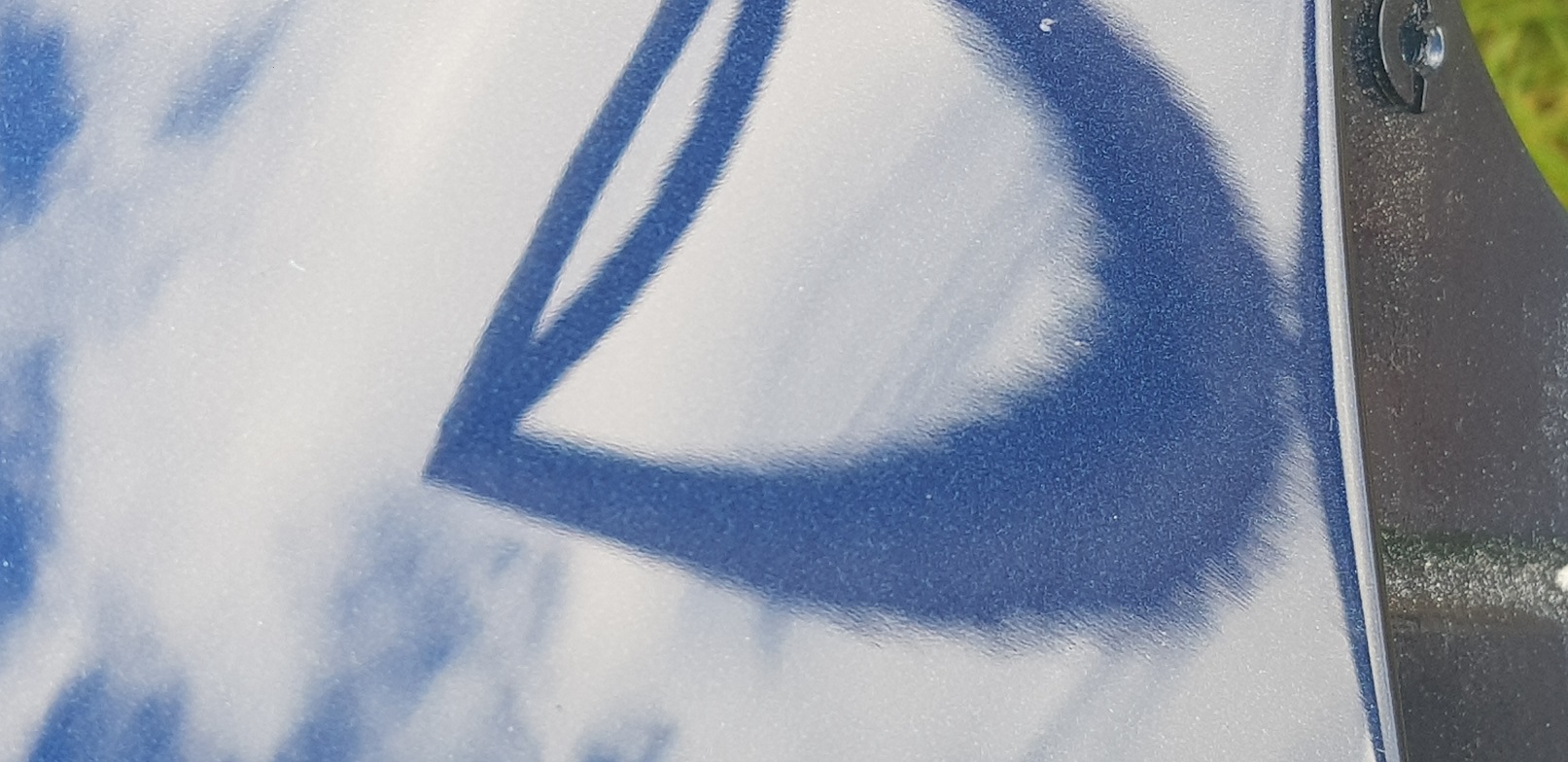

Hi guys new here but not new to detailing. I painted a replacement wing for my car and finished with 2k clear coat. let it dry for 5 days and then removed the orange peel with 2000 grit 3m paper, there wasnt much peel so didnt take long. I brought the gloss back with M101 and LC purple wool and finished with carpro reflect on a finishing pad and the finish looks perfect.

However look real close at the right angle and I can see tiny score lines the 2000 grit left, these are not tracers. My confusion is that M101 and wool should easily remove 2000 grit marks, which it did....but also didnt lol.

Now im not in the bodyshop or detailing trade, these are just hobbies so it could be something to do with the paint but I doubt that as temperature and humidity were fine, paint was mixed to spec and sprayed as per tech sheet.

Also to note im doing hand sanding, no DA sanding. I did follow up with 2500, 3000 and 5000 which gave a perfect finish but I thought just doing 2000 to save time would work out but just not happy about the score lines.

IMG-20170928-WA0001 by joe blogggs, on Flickr

IMG-20170928-WA0001 by joe blogggs, on Flickr

20170928_123958 by joe blogggs, on Flickr

20170928_123958 by joe blogggs, on Flickr

20170928_124119 by joe blogggs, on Flickr

20170928_124119 by joe blogggs, on Flickr

20170928_154054 by joe blogggs, on Flickr

20170928_154054 by joe blogggs, on Flickr

As you can see these arnt glass like reflections. I did do my old cars factory paint bonnet upto 3000 and it came out like glass. I didnt think leaving out 3k would make that big of a difference and really I thought M101 and wool should be able to remove 2k grit marks. Have I got a dodgy batch of papers or do I need to stop being lazy and sand up the grits to 3000?

20130717_190942_zps2ed8037a by joe blogggs, on Flickr

20130717_190942_zps2ed8037a by joe blogggs, on Flickr

However look real close at the right angle and I can see tiny score lines the 2000 grit left, these are not tracers. My confusion is that M101 and wool should easily remove 2000 grit marks, which it did....but also didnt lol.

Now im not in the bodyshop or detailing trade, these are just hobbies so it could be something to do with the paint but I doubt that as temperature and humidity were fine, paint was mixed to spec and sprayed as per tech sheet.

Also to note im doing hand sanding, no DA sanding. I did follow up with 2500, 3000 and 5000 which gave a perfect finish but I thought just doing 2000 to save time would work out but just not happy about the score lines.

IMG-20170928-WA0001 by joe blogggs, on Flickr

IMG-20170928-WA0001 by joe blogggs, on Flickr 20170928_123958 by joe blogggs, on Flickr

20170928_123958 by joe blogggs, on Flickr 20170928_124119 by joe blogggs, on Flickr

20170928_124119 by joe blogggs, on Flickr 20170928_154054 by joe blogggs, on Flickr

20170928_154054 by joe blogggs, on FlickrAs you can see these arnt glass like reflections. I did do my old cars factory paint bonnet upto 3000 and it came out like glass. I didnt think leaving out 3k would make that big of a difference and really I thought M101 and wool should be able to remove 2k grit marks. Have I got a dodgy batch of papers or do I need to stop being lazy and sand up the grits to 3000?

20130717_190942_zps2ed8037a by joe blogggs, on Flickr

20130717_190942_zps2ed8037a by joe blogggs, on Flickr