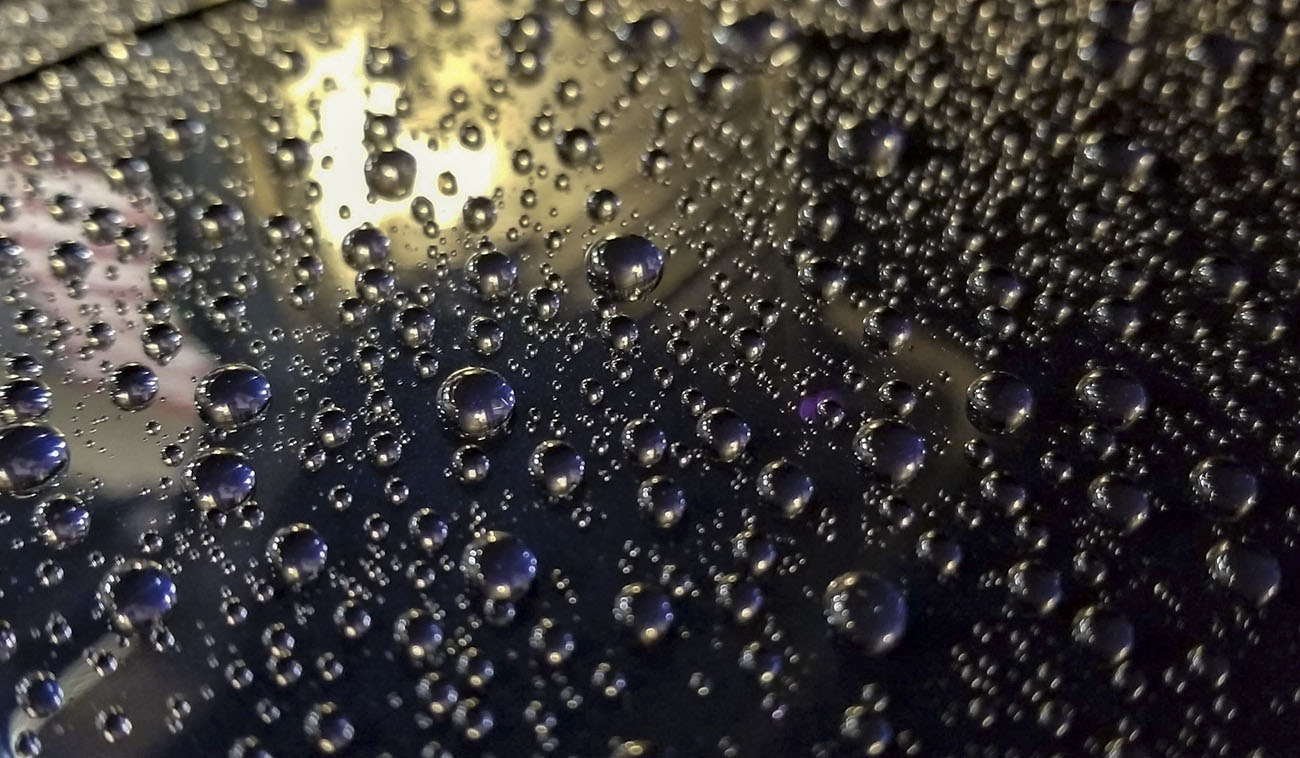

Both. Take Sonax Polymer Net Shield as an example. This has some of the tightest beading while at the same time sheeting water off the paint at the fastest rates. Crazy hydrophobic with a lower sliding angle, this will boost the self cleaning properties of the surface. Since I use a blower during my drying step, the more hydrophobic the surface is the more effective the blower is at removing the water from the paint. Hard water spots can be an issue on the paint regardless of how hydrophobic the surface is. In an attempt to reduce spotting, I would rather take steps to remove or avoid the source of the hard water rather than altering the hydrophobic behavior.

Some products that bead nicely can have that beading cling to the panel stronger than others, leaving a surface that has a higher comparative sliding angle. So if I take a spare hood with two different products on each half, mist it until I have a ton of beading on the panel and then begin to lift that hood on one end until the beading starts to fall off, the product with the lower sliding angle will be the first to release the beading from the surface, it does this at a lower angle. So on vertical panels if I spray a product down that beads nicely but has a high sliding angle, I'll see more beading clinging to this surface. Polymer Net Shield has a lower sliding angle, so more water beads will fall off of the surface if sprayed down exactly the same. Both the high contact angle (tighter beading) and lower sliding angle pair up to produce the insane sheeting rates.

Some refer to the better "sheeting" products as the ones that are less hydrophobic, flooding the panel will produce a nice sheet that runs off the surface at a consistent rate, removing a large portion of the water. As long as the product has some form of durable water signature that I can attest to it surviving on the paint then this is great, but I definitely prefer the most hydrophobic products I can get my hands on.