allenk4

In time out

- Mar 12, 2013

- 4,845

- 0

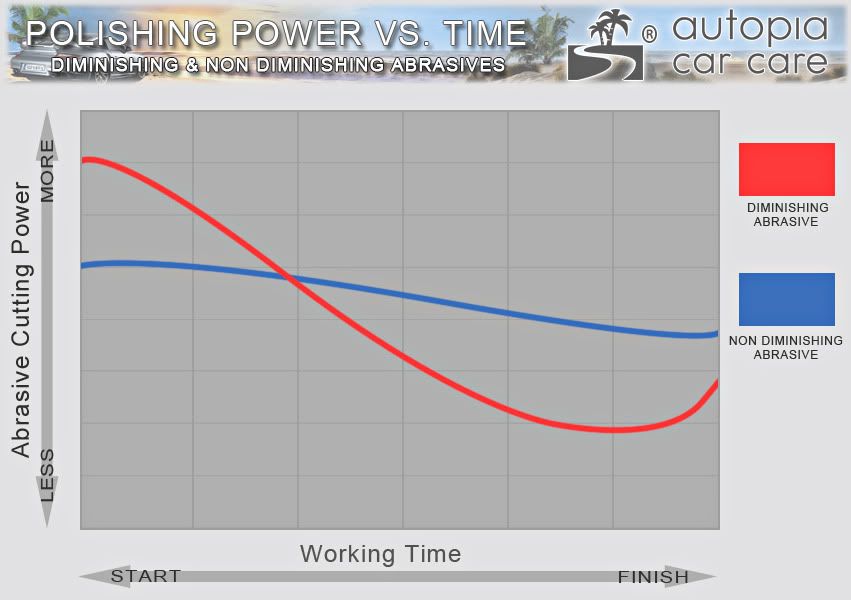

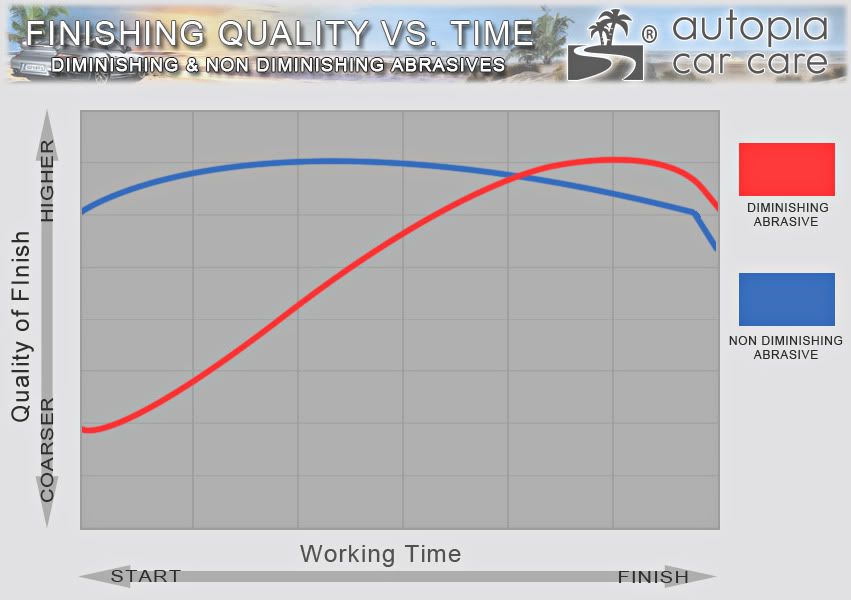

I found this over on Sister Forum Autopia and thought it was helpful to me understanding the differences in how the two work and how to work them.

The Difference Between Diminishing and Non-Diminishing Abrasive Polishes - Autopia Forums - Auto Detailing & Car Care Discussion Forum

My question is: I was recently doing 4 passes with Wolfgang Total Swirl Remover using an orange CCS pad with medium pressure followed by two passes with almost no pressure.

When I do the last two passes, sometimes small "Peas" of polish fly out from underneath the pad. It doesn't always do it? Is this an indication that I overworked the polish?

The Difference Between Diminishing and Non-Diminishing Abrasive Polishes - Autopia Forums - Auto Detailing & Car Care Discussion Forum

My question is: I was recently doing 4 passes with Wolfgang Total Swirl Remover using an orange CCS pad with medium pressure followed by two passes with almost no pressure.

When I do the last two passes, sometimes small "Peas" of polish fly out from underneath the pad. It doesn't always do it? Is this an indication that I overworked the polish?