allenk4

In time out

- Mar 12, 2013

- 4,845

- 0

5" pads to polish a whole car? Would take wayyyy too long, IMO. 5.5" is small enough!! LOL

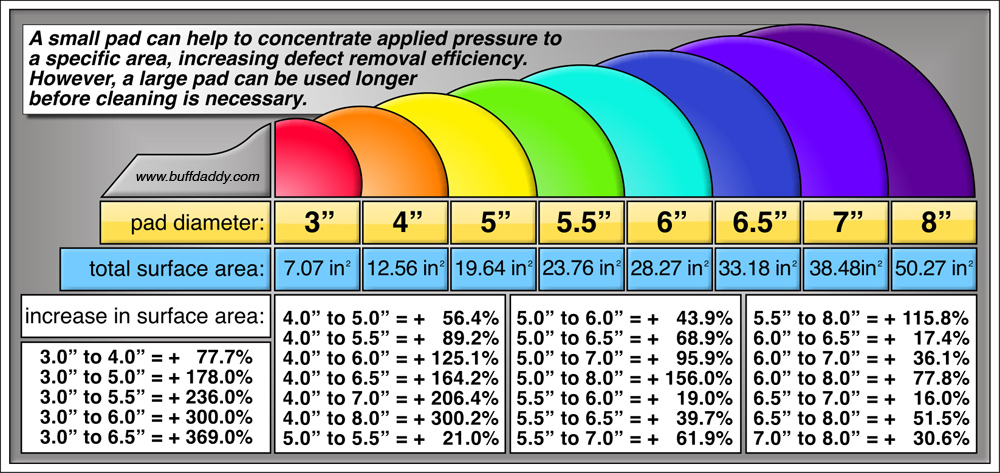

This quote made me think and get out the calculator

a = pi * r2

5" pad surface area = 19.63 square inches

5 1/2" pad surface area = 23.75 square inches

So yes, the 5 1/2" pad is 21% larger, so theoretically it saves you 52 minutes on a 4 hour polishing job

The huge difference would be going from 5" to 6 1/2'; which is almost 70% larger and would reduce a 4 hour job to just 1 hour and 12 minutes.

I personally do not believe that these numbers hold up in the real world.