Hello friends

A very good Thursday from Mauritius

This detailing job took over 5 days, from decontamination to coating, loads of defects removal and paint leveling.

Upon arrival:

Wash:

2BM method using mf wash mitt

Local car shampoo and APC mix

To the wheels

Washed already:

close-up of contaminants

Decontamination with Sonax full effect + Clay

in- process

Ready to be coated and protected

To the paintwork

Clay

Assessing the work to be done

Not easy to be noticed. On this color, it’s as if the defects have got “shyness DNA”

From previous respray job, rubber trims damaged! I was very sad for the friend who brought his Honda to me. Little or nothing I could do for that.

NEW paint defect (at least for a newbie like me, doing detailing as a passion)

More familiar

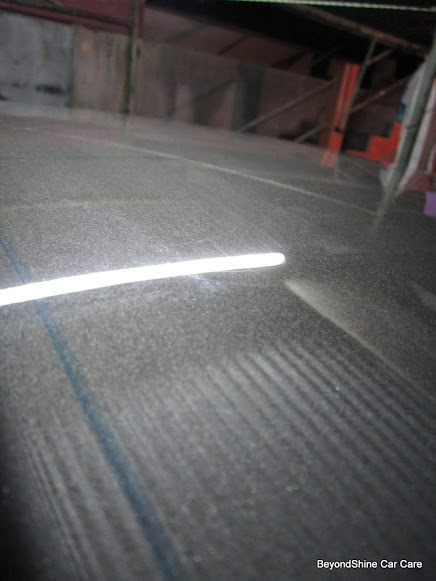

light scratches and RIDS, full of swirls but the metallic flakes just make it difficult to be captured.

The headlights

wait, not yet over

the lower sections

subsurface defect

Look

close-up

same on both sides of the rear bumper

Paint correction:

The paint has sanding marks and scratches beaneath the clear-coat. I had to proceed with extreme caution and to add, Hondas are the champion of soft paints.

Tools: Makita rotary, Flex 3401

Polishes: Menz FG 400, 203S, PO85rd

Pads: Carpro denim pads, LC white, LC HT Crimson, LC white

Glass: DP Glass restorer with glass polishing pads, Opti-sealed

Wipe down : IPA mix

Coating: Opticoat with supplied applicator, wiped with suede mf towels (better than normal mf towel IMO)

Trims & tyres: CG new look trim

After correction

a spot or 2 remain, would have needed more clear coat removal

The roof

close-up

More swirls appearing due to a flatter surface, holograms are there too from the compounding step

My friends

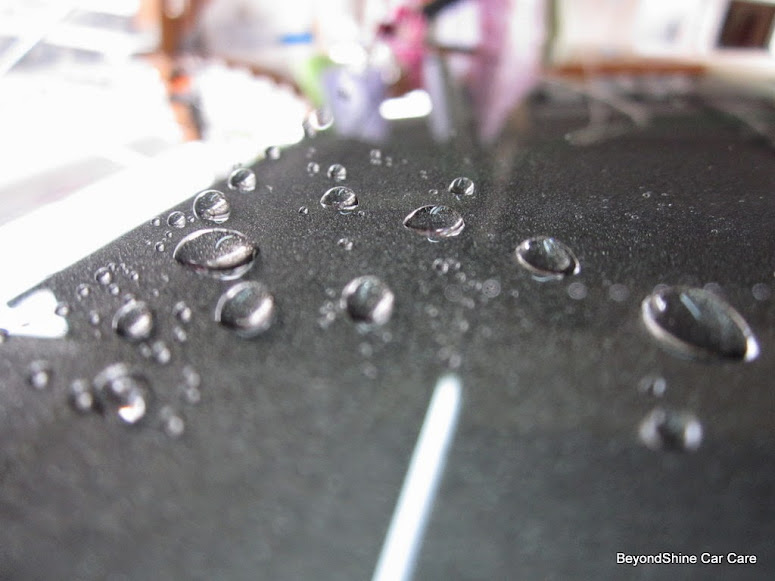

Beading during the polishing stage

Checking and checking

TA DA

Attending to the details

Focussed

menz 203s

rare incidence: Shot by Mrs

extreme close-up

A very good Thursday from Mauritius

This detailing job took over 5 days, from decontamination to coating, loads of defects removal and paint leveling.

Upon arrival:

Wash:

2BM method using mf wash mitt

Local car shampoo and APC mix

To the wheels

Washed already:

close-up of contaminants

Decontamination with Sonax full effect + Clay

in- process

Ready to be coated and protected

To the paintwork

Clay

Assessing the work to be done

Not easy to be noticed. On this color, it’s as if the defects have got “shyness DNA”

From previous respray job, rubber trims damaged! I was very sad for the friend who brought his Honda to me. Little or nothing I could do for that.

NEW paint defect (at least for a newbie like me, doing detailing as a passion)

More familiar

light scratches and RIDS, full of swirls but the metallic flakes just make it difficult to be captured.

The headlights

wait, not yet over

the lower sections

subsurface defect

Look

close-up

same on both sides of the rear bumper

Paint correction:

The paint has sanding marks and scratches beaneath the clear-coat. I had to proceed with extreme caution and to add, Hondas are the champion of soft paints.

Tools: Makita rotary, Flex 3401

Polishes: Menz FG 400, 203S, PO85rd

Pads: Carpro denim pads, LC white, LC HT Crimson, LC white

Glass: DP Glass restorer with glass polishing pads, Opti-sealed

Wipe down : IPA mix

Coating: Opticoat with supplied applicator, wiped with suede mf towels (better than normal mf towel IMO)

Trims & tyres: CG new look trim

After correction

a spot or 2 remain, would have needed more clear coat removal

The roof

close-up

More swirls appearing due to a flatter surface, holograms are there too from the compounding step

My friends

Beading during the polishing stage

Checking and checking

TA DA

Attending to the details

Focussed

menz 203s

rare incidence: Shot by Mrs

extreme close-up