Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 6

More is better? Amps - Watts - Volts and Rupes Polishers

On page 8 of the below thread the discussion turns to a talk about Amps & Watts as it relates to more powerful tools.

SEMA Release of Rupes - Page 8

I'm not an electrical engineer and don't care to become one and I also don't have the time or inclination to solve the issue of whether more is better when it comes to power tool.

That said, in Post #85 of the above thread I did say I would share what Marco D'Inca told me at SEMA on the topic of trying to determine the correction power of a tool by simply or only going by the tools rated power needs as rated by Amps and Watts.

And to preface this discussion, my Auto Shop Teacher in High School tried his hardest to explain this to our class using some weird Dirt Bike jumping over a ditch analogy and his explanation didn't help back then and I still don't know what he was talking about even to today.

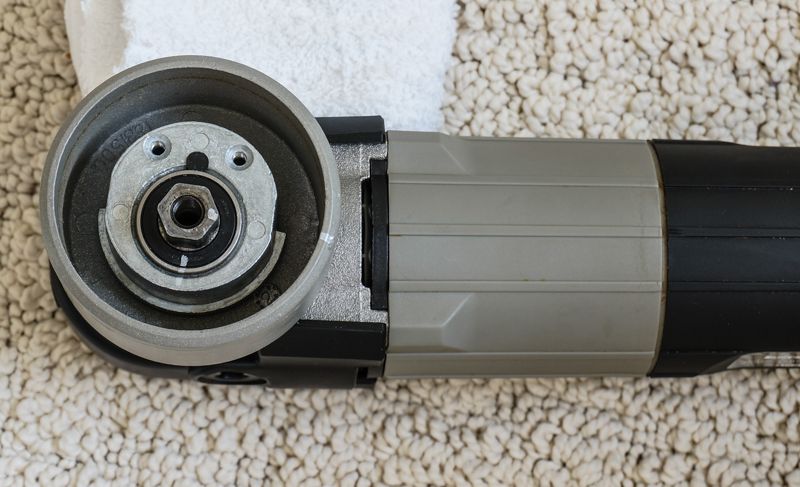

Here's what Marco said and this of course is a paraphrase and I'll use a picture below to try to help make the point.

Marco said,

The amount of amps or watts a tool uses does not automatically equate to the efficiency of the tool.

Let's look at that again,

The amount of amps or watts a tool uses does not automatically equate to the efficiency of the tool.

Then he used a miles per gallon analogy with cars to explain tool efficiency which I found easier to understand than the dirt bikes jumping a ditch analogy my high school shop teacher tried to use with the class.

If you have two cars and one is large and has a big powerful engine and one is small and has a smaller, more efficient engine, the smaller car will go further on a gallon of gas than the larger vehicle.

For the owner of the larger vehicle to tout that their car uses more gas to go the same distance or for one tool to use more power to do the same work is not a benefit. It's s sign of an inefficient motor.

At least that's how I remember the conversation and keep in mind, it's very busy when working inside a booth at a show like SEMA.

Now here's the picture, Nick's car can go further on a gallon of gas than my truck.

I think what Marco is saying is that he can get his tools to do the same type of work without having to use as much power as the design of electrical motors in other tools.

Or Nick and I can travel certain number of miles down the road but Nick can arrive at the same destination, going the same speed but he won't need as much gas or power as I will.

Don't know if that helps or hurts but I said I would post what was explained to me at SEMA and I kept my word.

You guys can hash out the electrical details...

Hey Nick? Want to race?

On page 8 of the below thread the discussion turns to a talk about Amps & Watts as it relates to more powerful tools.

SEMA Release of Rupes - Page 8

I'm not an electrical engineer and don't care to become one and I also don't have the time or inclination to solve the issue of whether more is better when it comes to power tool.

That said, in Post #85 of the above thread I did say I would share what Marco D'Inca told me at SEMA on the topic of trying to determine the correction power of a tool by simply or only going by the tools rated power needs as rated by Amps and Watts.

And to preface this discussion, my Auto Shop Teacher in High School tried his hardest to explain this to our class using some weird Dirt Bike jumping over a ditch analogy and his explanation didn't help back then and I still don't know what he was talking about even to today.

Here's what Marco said and this of course is a paraphrase and I'll use a picture below to try to help make the point.

Marco said,

The amount of amps or watts a tool uses does not automatically equate to the efficiency of the tool.

Let's look at that again,

The amount of amps or watts a tool uses does not automatically equate to the efficiency of the tool.

Then he used a miles per gallon analogy with cars to explain tool efficiency which I found easier to understand than the dirt bikes jumping a ditch analogy my high school shop teacher tried to use with the class.

If you have two cars and one is large and has a big powerful engine and one is small and has a smaller, more efficient engine, the smaller car will go further on a gallon of gas than the larger vehicle.

For the owner of the larger vehicle to tout that their car uses more gas to go the same distance or for one tool to use more power to do the same work is not a benefit. It's s sign of an inefficient motor.

At least that's how I remember the conversation and keep in mind, it's very busy when working inside a booth at a show like SEMA.

Now here's the picture, Nick's car can go further on a gallon of gas than my truck.

I think what Marco is saying is that he can get his tools to do the same type of work without having to use as much power as the design of electrical motors in other tools.

Or Nick and I can travel certain number of miles down the road but Nick can arrive at the same destination, going the same speed but he won't need as much gas or power as I will.

Don't know if that helps or hurts but I said I would post what was explained to me at SEMA and I kept my word.

You guys can hash out the electrical details...

Hey Nick? Want to race?