Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oxidation

- Thread starter buckeye24

- Start date

- Thread starter

- #2

View attachment 58133When compounding oxidation off the hull of a boat is its bad enough do you have to damp sand the gelcoat or can you cut though it with a good quality heavy compound

Rsurfer

Well-known member

- Jan 26, 2007

- 14,159

- 26

Does it matter where I do the test spot would you have any advice on where I should do the test spot

Find the worse area and do a 2'X2' section. Colored area will show up best (not on vinyl)

Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 7

When compounding oxidation off the hull of a boat is its bad enough do you have to damp sand the gelcoat or can you cut though it with a good quality heavy compound

To answer your question....

If the oxidation is deep, that is not just on the surface but goes deep into the pigmented layer of polyester resin called "gel-coat", then it's faster, easier and more effective to machine sand off the dead, oxidized gel-coat than it is to PUSH HARD for hours against the hull using a rotary buffer.

I cover this in-depth in my boat detailing how-to book on page 70 and 71 and then the rest of that chapter shows how to do both methods.

Here's your boat picture,

If you have a rotary buffer then I'd recommend using the push hard for hours method as hand or machine sanding a boat isn't something most people should tackle without some experience and/or guidance.

You're going to want an aggressive wool cutting pad and a heavy cutting compound. For anyone that has read any of my posts over the years you'll notice I ALWAYS stress the importance of using GREAT ABRASIVE TECHNOLOGY when buffing out clearcoats but in reality it's important for anything that's important to you.

I'd get a couple of quarts of the Marine 31 Captain’s One-Step Compound & Polish.

Cut the boat hard with this compound and you'll remove the oxidation and only leave behind hologram scratches from the FIBERS of the wool pad. You can then easily remove the holograms by switching over to a foam cutting pad and then use a good one-step cleaner/wax or if you want to do more steps hit the boat with a polish and then wax.

A one-step cleaner/wax will remove the hologram scratches and leave the boat protected - that makes this boat detailing project a 2-step process --> Compound then cleaner/wax.

A three step would be,

Compound, polish and then wax

A 4-step would be,

Compound, polish, chemically strip and the coat

I'm happy to walk you through whatever process you want to use, just let me know...

Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 7

After this initial detailing session you're going to want to become best friends with a good one-step cleaner/wax to maintain the hull so you don't have to do this incredibly labor intense compounding step again.

A one step cleaner/wax will,

Remove the oxidation

Polish the gel-coat to a high gloss

Leave the gel-coat protected

His is a heavy cut cleaner/wax and it actually works really well when a boat isn't as bad as the boat in your pictures.

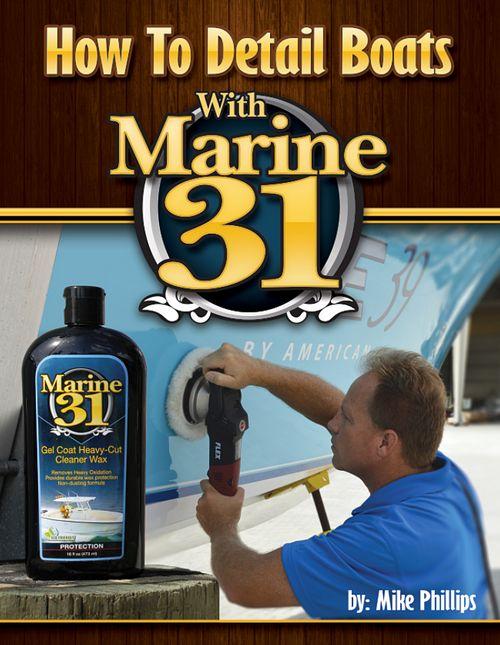

Marine 31 Gel Coat Heavy-Cut Cleaner Wax 32 oz

And just to note - the most valuable piece of real-estate on a book is the COVER. You can send a message with the PICTURE.

Look at the tool I'm holding. Look at the pad I have on the tool. This is a message.

And that tool with a wool pad and a great cleaner/wax is a great way to MAINTAIN a boat after the initial detailing process to keep away the oxidation.

Paperback book - How To Detail Boats With Marine 31 by Mike Phillips

A one step cleaner/wax will,

Remove the oxidation

Polish the gel-coat to a high gloss

Leave the gel-coat protected

His is a heavy cut cleaner/wax and it actually works really well when a boat isn't as bad as the boat in your pictures.

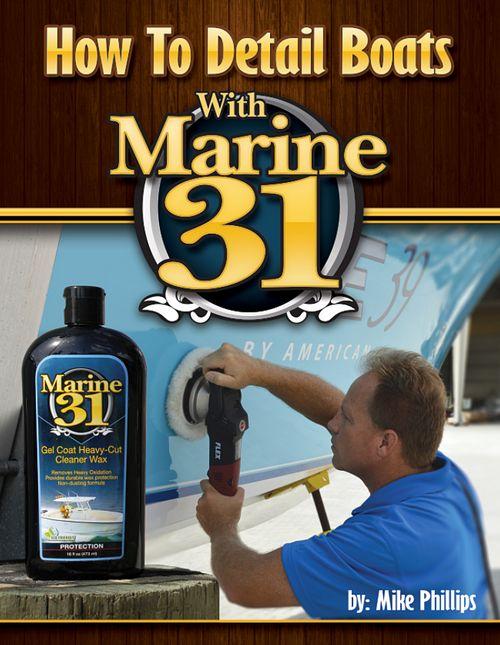

Marine 31 Gel Coat Heavy-Cut Cleaner Wax 32 oz

And just to note - the most valuable piece of real-estate on a book is the COVER. You can send a message with the PICTURE.

Look at the tool I'm holding. Look at the pad I have on the tool. This is a message.

And that tool with a wool pad and a great cleaner/wax is a great way to MAINTAIN a boat after the initial detailing process to keep away the oxidation.

Paperback book - How To Detail Boats With Marine 31 by Mike Phillips

Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 7

I would like to give a go with the 3 step and I do have your book it's good but maybe you can help me out s bit more please

Simple

Read pages 56 to 69

In that section I show you how to do a three-step process without sanding and cover these tool options

Rotary buffer

FLEX 3401

Porter Cable 7424XP

Cyclo Polisher

RUPES BigFoot 21 and 15

And you can mix and match, for example start by cutting with a rotary buffer and for the next two steps switch over to ANY orbital for hologram free results.

Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 7

Here's an old trick...

Start by washing the oxidized gel-coat with Comet or Bon Ami first, this will remove all the loose oxidation. Use some pressure when rubbing the wash mitt or a wash cloth over the surface.

Start by washing the oxidized gel-coat with Comet or Bon Ami first, this will remove all the loose oxidation. Use some pressure when rubbing the wash mitt or a wash cloth over the surface.