IID

Well-known member

- Sep 11, 2010

- 2,207

- 25

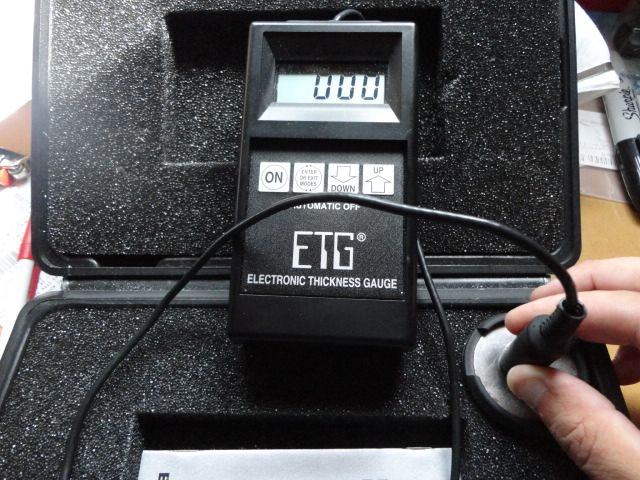

Today I wanted to play with my ETG Electronic Thickness Gage to check how much clear coat is removed whille polishing and then added using CQuartz Finest,on my daily driven 300C SRT Design.

Machine calibrated and I have the unit set in micons:

Readings before polishing

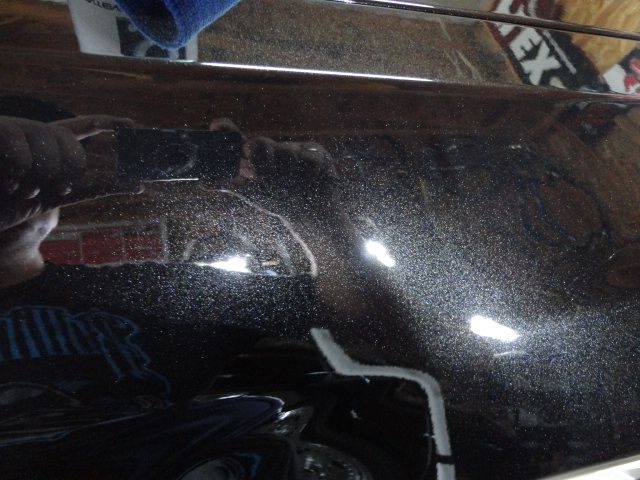

For demostration,i'll be using the front passenger quarter panel:

NOTE:All Readings in Micron's!

122

126

120

120mil

120mil

133

117 near the body line transition (this is why it's extreamly important to take cautions when polishing close to these area's)

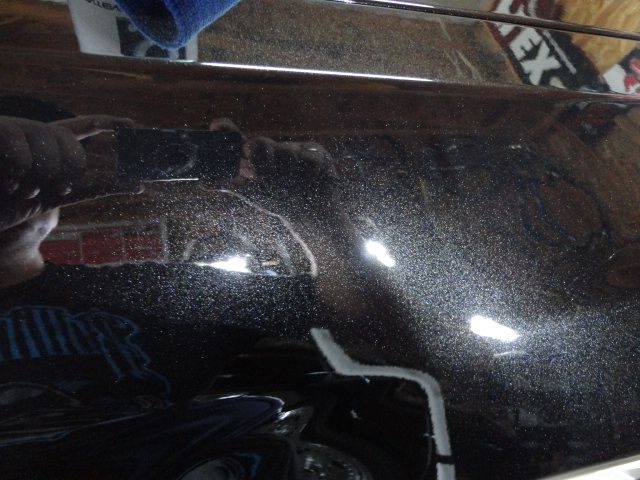

For the polishing demo,I'm using Menz PF2500/Uber Green Pad/FLEX PE:

For my process,i'll make three to four section passes with the FLEX on speed 3:

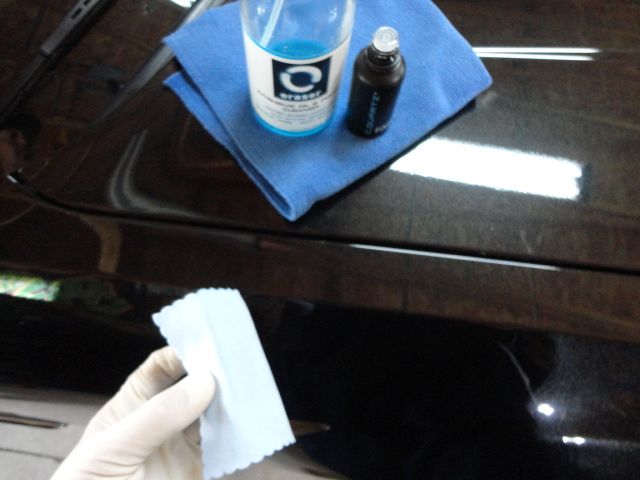

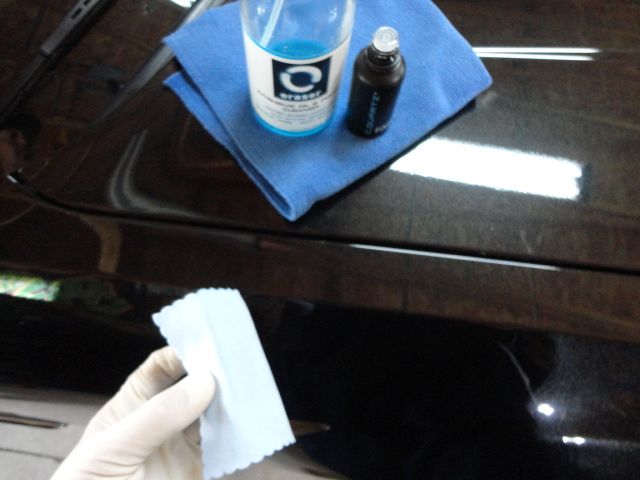

after polishing,I do a final wipe down with CarPro Eraser:

Now it's time to take another reading to see how much clear was removed in their respected polished area's:

118 / prior 122

125 / prior 126

119 / prior 120

128 / prior 133

116 / prior 117 (again,near the body line)

Now i'm going to apply the CQF,I will do 2 layers:

One layer:

Two layer:

Knocked down any high spots before the CQF starts to cure/harden:

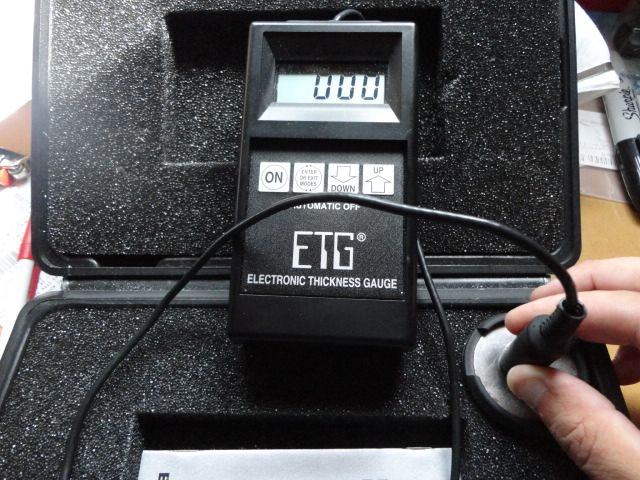

Ok,now lets check the thickness again after the (2) coats of CQF:

After CQF 127/ After polishing 118 /Original 122

After CQF 130 / After polishing 125 / Original 126

After CQF 120 / After polishing 119 / Original 120

After CQF 135 / After polishing 128 / Original 133

After CQF 123 / After polishing 116 / Original 117

Now I fully understand each location is in the approximent area(s) when taking the measurements but i'm just trying to show you all:

*Amount of clear abraided off each section*

*Amount of coating that adds to each sections thickness*

On a average,the polishing took off an average between the five sections is 2.4

On a average,the CQF coating added 5.8 on each section

Take from this thread what you will but I thought I would have a little fun learning a few things and it was fun doing it :xyxthumbs:

Machine calibrated and I have the unit set in micons:

Readings before polishing

For demostration,i'll be using the front passenger quarter panel:

NOTE:All Readings in Micron's!

122

126

120

133

117 near the body line transition (this is why it's extreamly important to take cautions when polishing close to these area's)

For the polishing demo,I'm using Menz PF2500/Uber Green Pad/FLEX PE:

For my process,i'll make three to four section passes with the FLEX on speed 3:

after polishing,I do a final wipe down with CarPro Eraser:

Now it's time to take another reading to see how much clear was removed in their respected polished area's:

118 / prior 122

125 / prior 126

119 / prior 120

128 / prior 133

116 / prior 117 (again,near the body line)

Now i'm going to apply the CQF,I will do 2 layers:

One layer:

Two layer:

Knocked down any high spots before the CQF starts to cure/harden:

Ok,now lets check the thickness again after the (2) coats of CQF:

After CQF 127/ After polishing 118 /Original 122

After CQF 130 / After polishing 125 / Original 126

After CQF 120 / After polishing 119 / Original 120

After CQF 135 / After polishing 128 / Original 133

After CQF 123 / After polishing 116 / Original 117

Now I fully understand each location is in the approximent area(s) when taking the measurements but i'm just trying to show you all:

*Amount of clear abraided off each section*

*Amount of coating that adds to each sections thickness*

On a average,the polishing took off an average between the five sections is 2.4

On a average,the CQF coating added 5.8 on each section

Take from this thread what you will but I thought I would have a little fun learning a few things and it was fun doing it :xyxthumbs: