Captainobvious

New member

- Oct 3, 2014

- 16

- 0

I was hoping you all could point me in the right direction. I'm working on a couple of aluminum pieces which I've used the cross-sanding technique from 320 grit (it was pretty deeply marred) up to 2000 grit wet-sanding. I'm still left with scratches though from the sanding steps which are easily visible and I need to find the most effective way of doing a cut on the pieces to remove these scratches so I can finish with a highly polished finish.

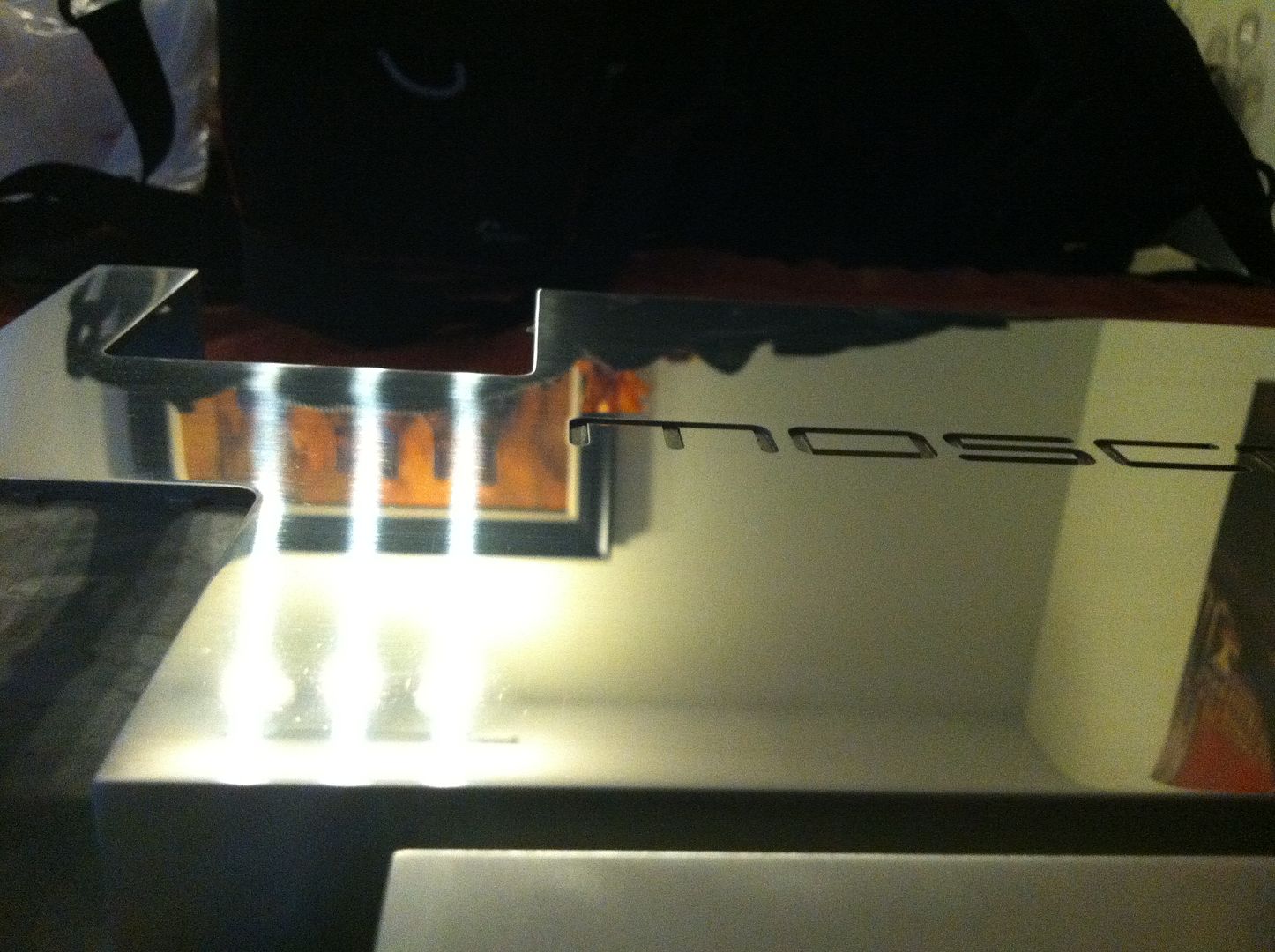

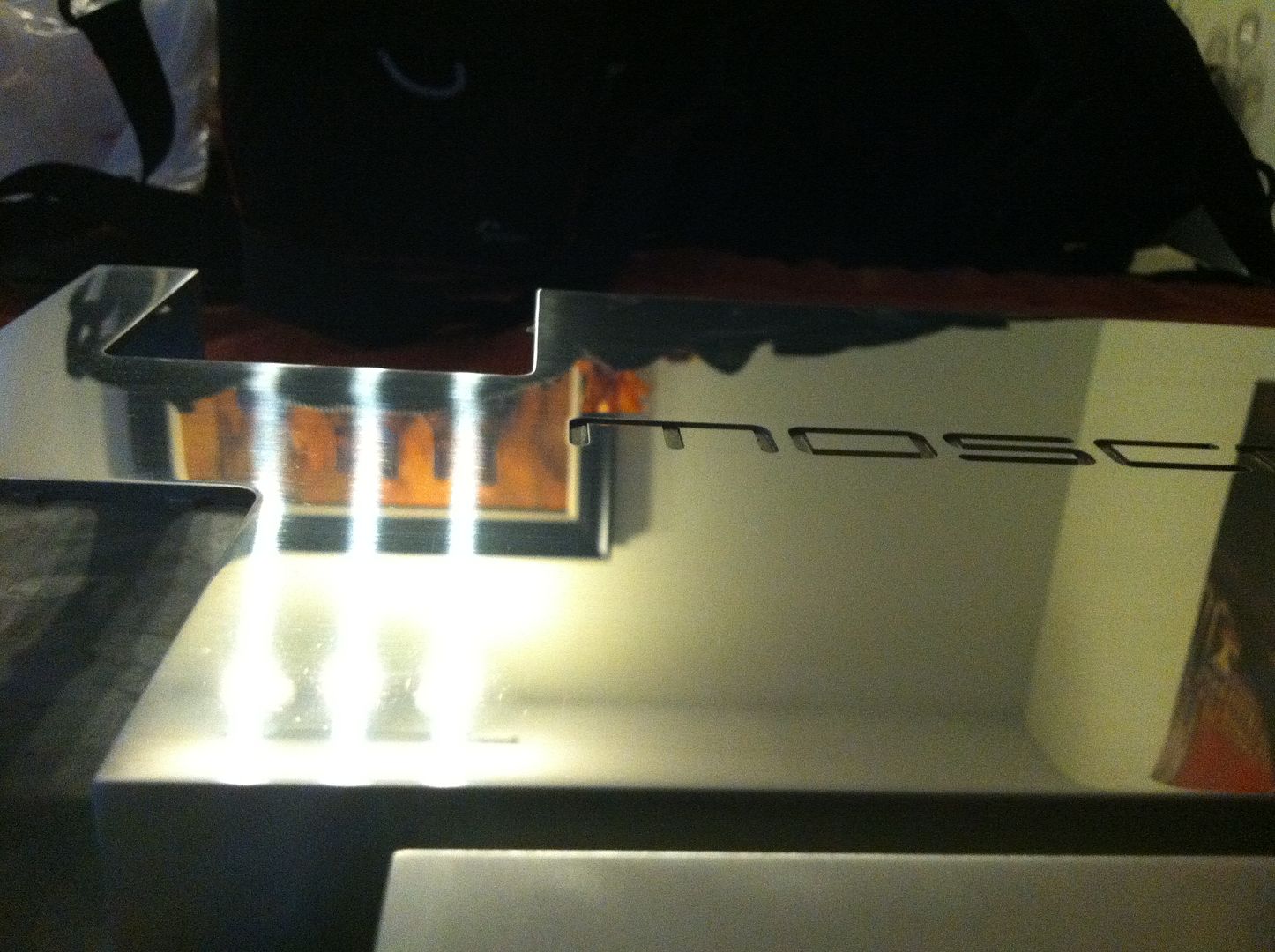

Started like this:

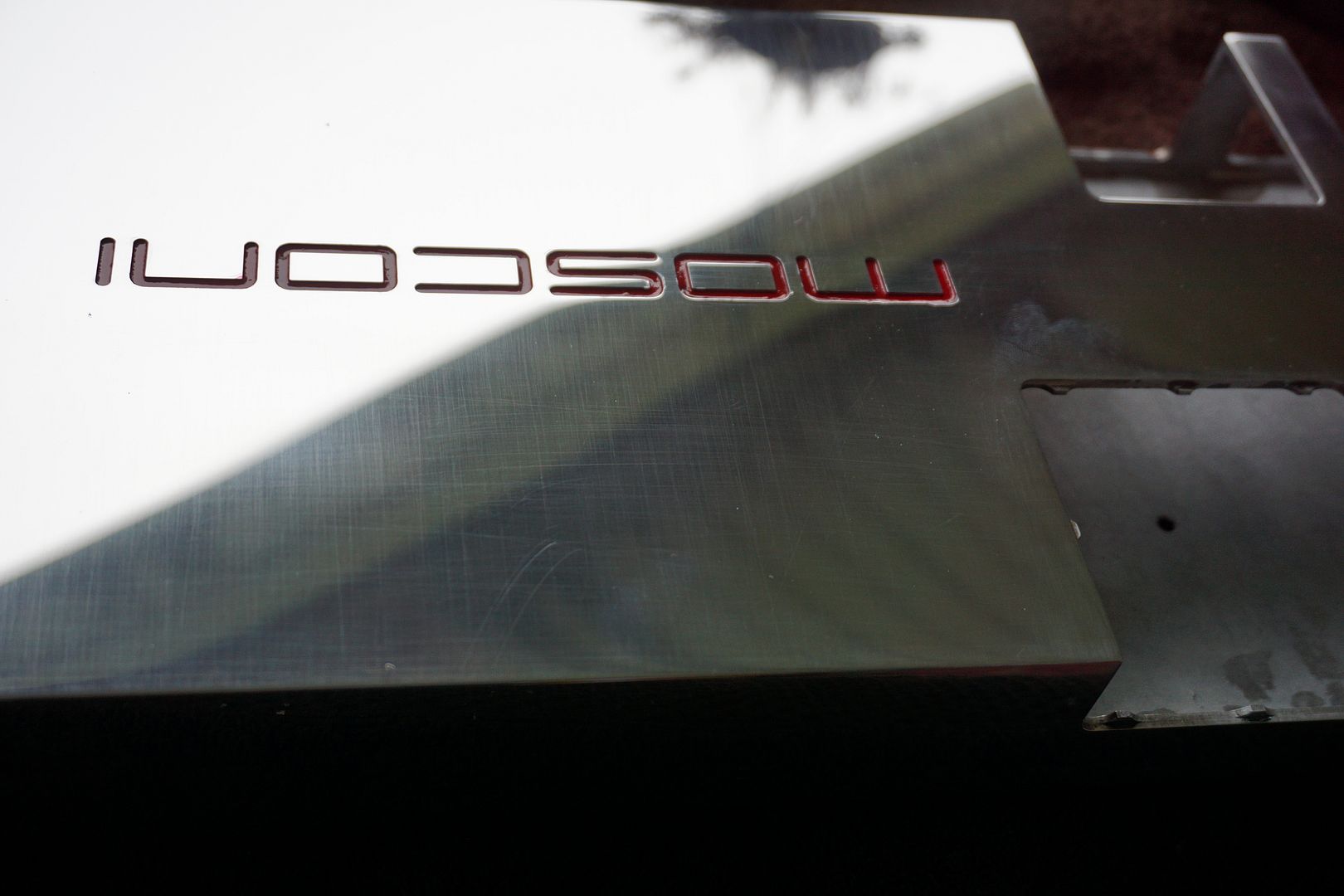

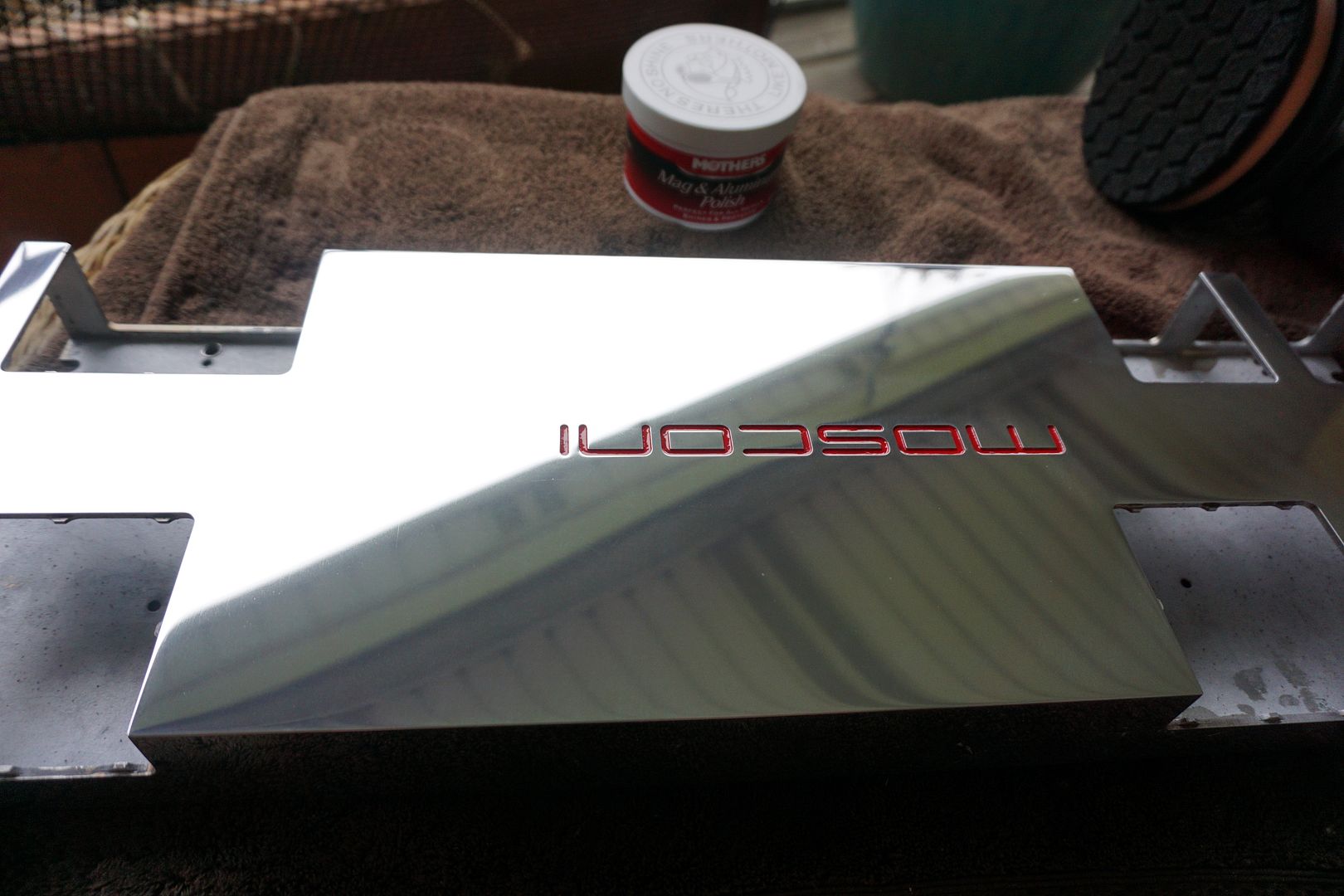

Got the two pieces looking much better, but they still show scratches like this:

I have a rotary buffer (7") and a DA polisher (6"). I see some Blackfire pads and polishes available here on the site but wasn't sure if they were the right item for the job.

Pads

(Level one): BLACKFIRE Level 1 Pre-polishing Wool Pad, compounding pad

(Level two): BLACKFIRE Level 2 Metal Polishing Wool Pad

Polishes

Heavy Cut Compound: BLACKFIRE Heavy Cut Aluminum Compound, metal polish

Fine Cut Compound: BLACKFIRE Fine Cut Aluminum Polish, metal polish, wheel polish

Finally, is this (below) finishing polish basically a similar paste to the Mothers Aluminum wheel polish? I have a bunch of that but don't want to buy more of the same type product if not needed.

: BLACKFIRE Wet Diamond Aluminum Show Polish, metal polish

Thanks you for any assistance you can offer. This is my first attempt at doing any real metal polishing.

Started like this:

Got the two pieces looking much better, but they still show scratches like this:

I have a rotary buffer (7") and a DA polisher (6"). I see some Blackfire pads and polishes available here on the site but wasn't sure if they were the right item for the job.

Pads

(Level one): BLACKFIRE Level 1 Pre-polishing Wool Pad, compounding pad

(Level two): BLACKFIRE Level 2 Metal Polishing Wool Pad

Polishes

Heavy Cut Compound: BLACKFIRE Heavy Cut Aluminum Compound, metal polish

Fine Cut Compound: BLACKFIRE Fine Cut Aluminum Polish, metal polish, wheel polish

Finally, is this (below) finishing polish basically a similar paste to the Mothers Aluminum wheel polish? I have a bunch of that but don't want to buy more of the same type product if not needed.

: BLACKFIRE Wet Diamond Aluminum Show Polish, metal polish

Thanks you for any assistance you can offer. This is my first attempt at doing any real metal polishing.