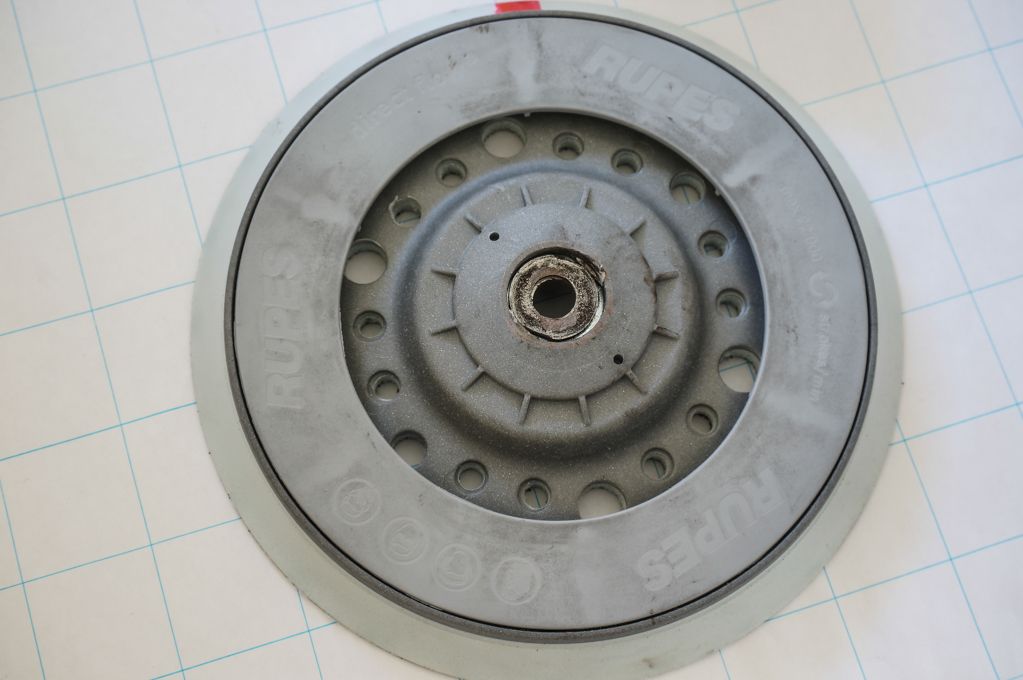

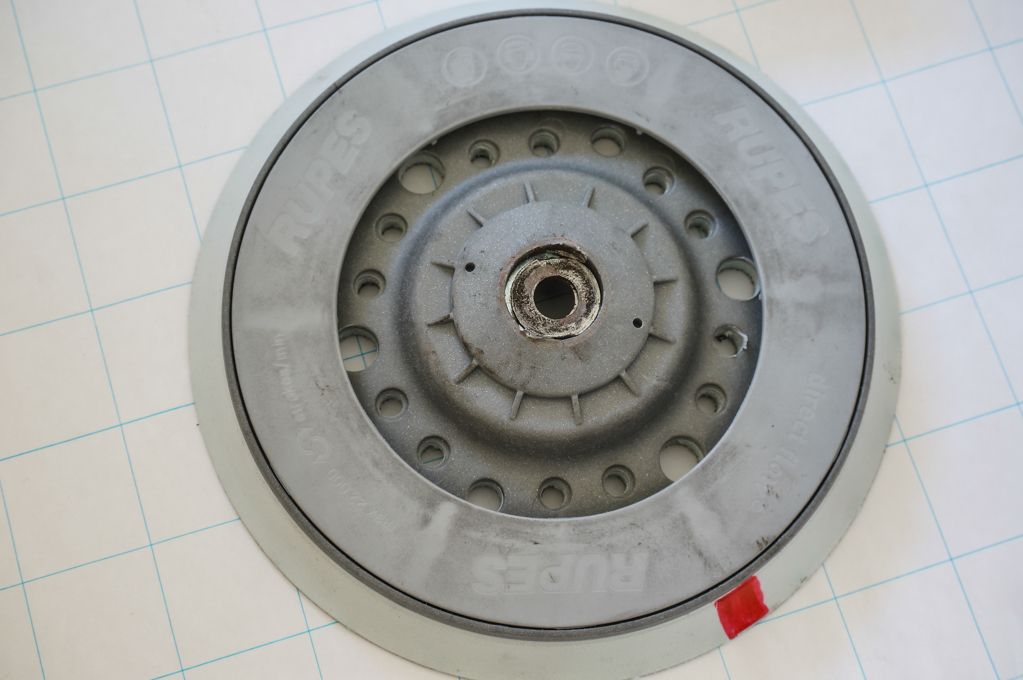

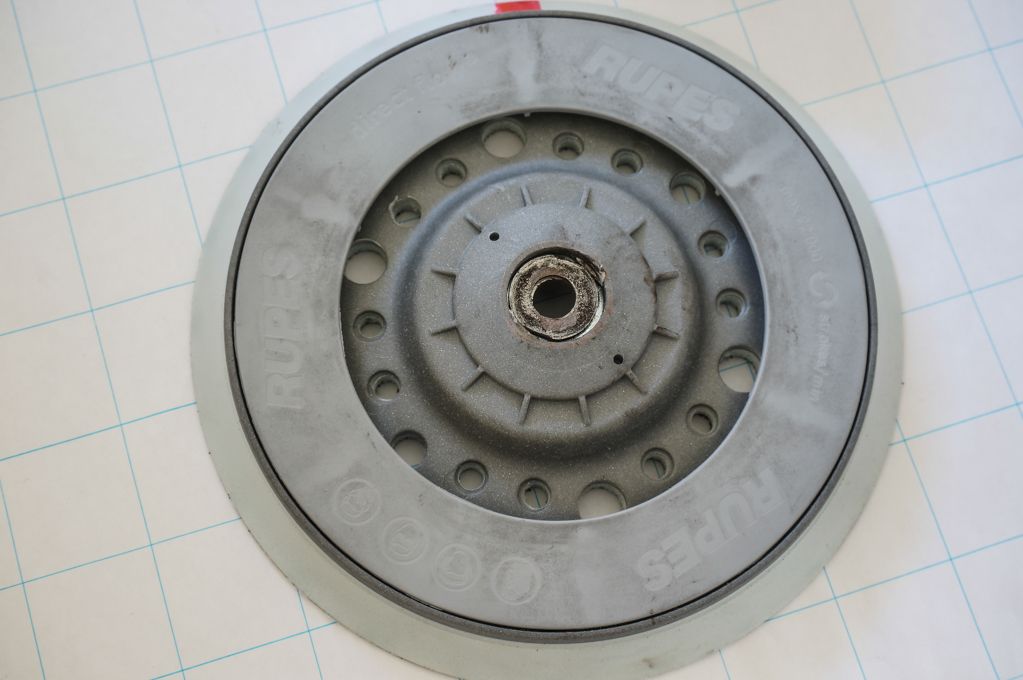

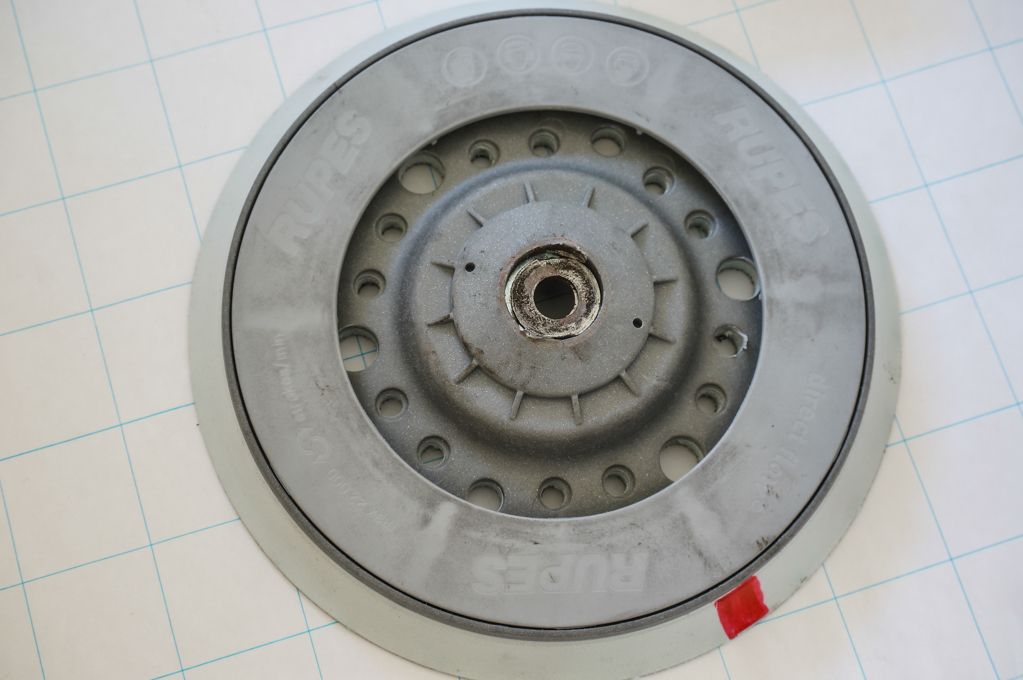

When I removed the 6" backing plate (with the washer mod) I noticed the plate must have shifted during operation since the edges of the washer where the sides are flattened have dug into the backing plate a bit, on opposite sides of the backing plate (see photos).

I had the backing plate tightened as much as the small allen wrench that comes with it can reasonably get it, considering you also have to hold the backing plate while tightening it, but it seems it needs to be tightened more than that. Probably the only way to be sure it's tight enough is to use a torque wrench.

Does anyone know the factory torque specification for the backing plate allen screw?

I know some people have said the screw was impossibly tight from the factory, so I guess it really needs to be that tight.

If anyone has a "factory fresh" machine and a torque wrench with a 5mm allen key I guess you could reverse engineer what the factory torque is(?)

As an unintended consequence of this, the washer is now frozen in its current location shown in the photo and I cannot pry it out.

I had the backing plate tightened as much as the small allen wrench that comes with it can reasonably get it, considering you also have to hold the backing plate while tightening it, but it seems it needs to be tightened more than that. Probably the only way to be sure it's tight enough is to use a torque wrench.

Does anyone know the factory torque specification for the backing plate allen screw?

I know some people have said the screw was impossibly tight from the factory, so I guess it really needs to be that tight.

If anyone has a "factory fresh" machine and a torque wrench with a 5mm allen key I guess you could reverse engineer what the factory torque is(?)

As an unintended consequence of this, the washer is now frozen in its current location shown in the photo and I cannot pry it out.