I normally try and stay out of those discussions because there are too many variables associated with the longevity of coatings HOWEVER I would like to offer a tid bit of my chemistry background to the conversation.

Without making this conversion too technical (so please assume that in order to simplify my answer that some technicality have been ignored), I will offer that in the world of chemistry that 2 main basic bond exists:

1)

Ionic (weak covalent, if you want to be technical)

2)

Covalent

A

chemical bond is defined as: a mutual attraction between two atoms resulting from a redistribution of their outer electrons.

An

ionic bond is formed when one atom accepts or donates one or more of its valence electrons to another atom. That makes them electrostatically attracted together. This bond can be easily broken by any other atoms which have greater electronegativity. A

covalent bond on the other hand is formed when atoms

share valence electrons, which makes this bond much harder to break, and barring exposure to those elements of disruption, this bond is stable and considered "permanent".

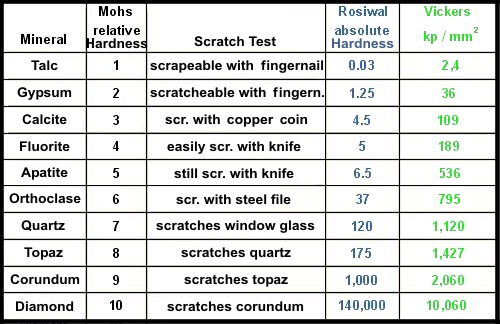

The coating technology I know most about is the Quartz technology (since I am a Finest installer, and researched this technology more extensively). Although other coating technology exist (resin based etc..) the basic chemistry still applies although they may differ little in their chemical reactions. In the CQuartz technology, the Si (silicon) in suspension gets delivered to the paint (or other substrate) where its carrier agents (solution) is allowed to evaporate. As it evaporates the Si atoms will try and find chemical stability and will readily pair with O (oxygen) to create the stable covalent molecule of SiO2 (aka. silicon dioxide). This nano-size molecule bonds to other molecule to form a matrix, which fills all those little imperfections in the paint, creating a layer thickness of 1-3 micron in thickness. So far because we are talking about a covalent chemical bond I am in complete sync with all those companies that claim "permanency". Barring any mechanical or chemical disruption of the matrix, you will have a substance that will technically last FOREVER.

Here is a advertising picture I created to promote my business, and CQuartz Finest which may give you a visual of what I am talking about.

Where my brain do find objection in those marketing

"shenanigans" of using the word PERMANENT stems in the fact that the bond that the matrix forms with the clear coat is an IONIC bond. There are no reagents in the clear coat (which is a stable matrix on its own) that will react to create a COVALENT bond with the nano-ceramic matrix. So please do yourself a favor and stop believing the hype. The only reason the CQuartz coating matrix stays in place is because you have a mechanical interlocking of the 2 structures, and a WEAK ionic bond (attraction) between the two matrix. AND this is REGARDLESS if you bring it in for regular checkups!!:nomore:

Clear coats are applied to base coat paint in the same way. They do NOT make a covalent bond and that is a reason why manufacturers don't put a "Permenant" label on their clear coats. Have you ever seen clear coat failure and complete delamination of the clear coat from the base coat?

Now in a perfect environment with no harsh UV rays, acid rain, exposure to industrial spraying, solvents, or contact with non-pH neutral solutions etc... than EVERY coating is permanent. But have you ever tested the pH of road grime, which we all get on vehicles!?!? Do you even know what that road grime is?? Simple answer, in most part it is a mix of engine, transmission, gear oil and other petroleum based products, mixed with contaminated soil and run off water from Lord knows where containing Lord knows what. In other words, definitely not a pH neutral mixture, but more a mixture of earth products and petroleum SOLVENTS!

Next time you are riding in the sunset with your honey and see this darkened area of pavement in the center of your lane remember that it is this road grime mixture I've spoke of and be afraid, be very afraid!!!