No worries. Basically, it's not that they use siloxane or not as the main coating ingredient, rather it's that the carrier solvents are similar and therefore after the product has already "hardened", the carrier solvent will not bond onto the coating itself properly, therefore something like Synergy will last only a month. To understand the bonding process on the geek level (Sorry, I geek out on this stuff.) most coatings are based on the main protection element (Silica Dioxide for example) then there is the carrier solvent that keeps it in its liquid form. Basically, an advanced version of paint thinner in most cases. Also the most expensive part of a coating. Then, the bonding agent. Most of them use a mixture of proprietary polymers (as in synthetic components) that keeps the main protection ingredient on the paint.

So, basically, the same carrier solvent will not do something to already cured or hardened Silica. Siloxane is the stuff in Reload, Hydro2, etc that has great beading and bonds easily. I don't believe Synergy has Siloxane in it, as Siloxane is typically used in more liquid applications than something like a wax. I could be wrong, and I'm sure it's possible to do it that way.

So for example, a product that does not use the same carrier solvents actually will last longer. For example overcoat is siloxane based. Cquartz UK and Kamikaze paint coatings are generally not. Different carrier solvents basically mean that layering has a better chance after product has cured. So if you look at a product that does not like being layered, it's because it will not allow the carrier solvent to evenly distribute the product and let it settle on top of the existing layer. Same carrier solvent means generally that it will try to layer on in a similar pattern which won't work.

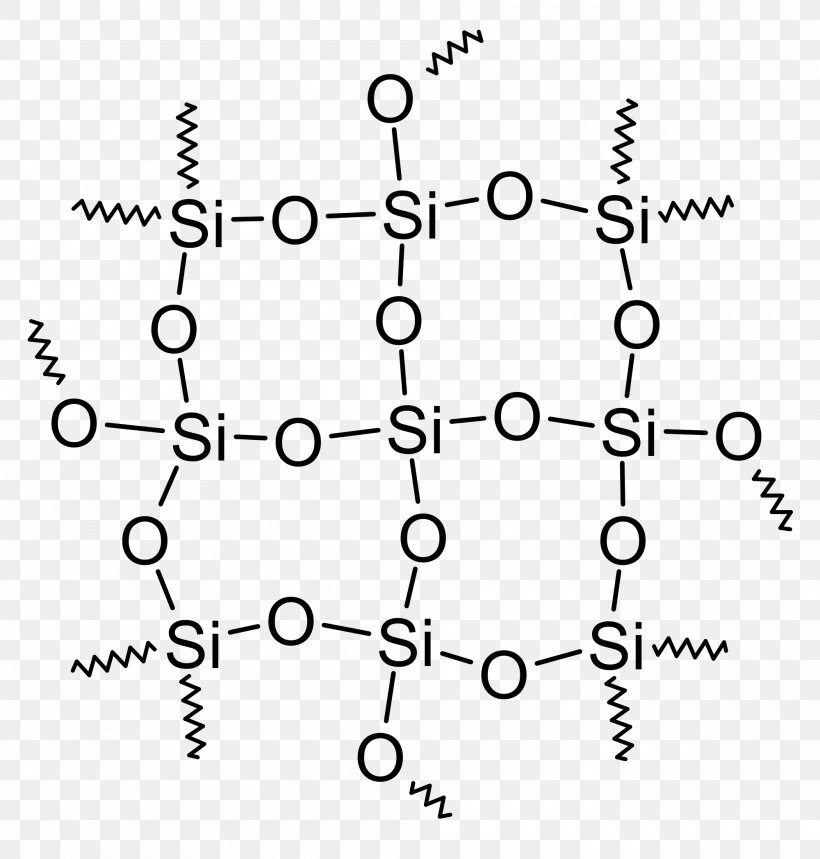

If you look at the image, just a general non-brand specific SiO2 layer. Different carrier solvent and different protective agent will mean it will try to seat itself in between the "spaces" on the initial layer. Some coatings are designed to layer on each other. It's also why putting on 20 layers of a coating wont' do anything. Each subsequent layer might just add on a tiny layer if there's even room in between the molecules to actually be able to do that. So the lack of durability from Synergy means that Synergy probably uses SiO2 in the wax and not siloxane, so a bit of wax oil and a bit of the SiO2 sits on top of the Cquartz SiO2 layer and resin, but not in a "chemically stable" manner. Basically, the ingredients in Synergy fail to establish a chemical bond with Cquartz UK, so durability is much lower than expected.

The beading differences is caused by something similar. Normally in a spray wax, the beading would be caused by a very thin but continuous layer of oil. Of course, on top of a coating, the oil does not form a "continuous" layer. Not only does it not bond properly, but the oil actually has small "breaks" in it (This is all microscopic) that show part of the coating. Hence, beading differences. So if you look at for example the image of the SiO2 layer, the wax sits in between and due to different element/resin sizes.

If you look at the diagram, the wax sits in between the small "spikes" as that is what causes hydrophobic features; not a completely flat surface but rather a surface like that. So now imagine the wax layer is sitting in between the spikes but beneath the highest point of the spikes. That's why you see different hydrophobic behaviour. On regular car clear coat, the surface is much flatter and the wax will sit straight on top.

Other factor is also, the SiO2 sits in that resin layer, the resin could be composed of a lot of different things. It's why there's also something called "thickness shrinkage." Usually due to resin choice/carrier resin. So for example, initial coat might be 1.5 micron. After curing and outgassing, it becomes 0.8 micron. It's also why Coating hardness does not matter. SiO2 has this hardness. That's nice. What is the hardness of the resin? That's what actually matters. At the end of the day, a coating is not a layer of glass. It's a layer of SiO2 or whatever it is, it's the resin.

If a spray product is not bonding properly, it could also be that the paint itself was not properly prepped. In the same way that wax (oil) will not bond to SiO2 and the bonding agent, the bonding agent will not bond to oil. Siloxane as well as silica carrier will not bond properly if oil is still on the surface. I make it a general rule before LSP (except for wax) to just spray the panel down and get rid of any oils or anything that MIGHT be on there.

I don't prep like that for wax, because wax is oil based and oil will bond onto the right type of oil. For example, a lot of Meguiar's products will bond better onto the polishing oils left after polishing. Chemical synergy. Exact opposite when it comes to topping ceramic products and the like.