Just to chime in, the rotary polisher is an awesome tool, you just need to invest some time behind it to learn how to make it dance on paint.

Wool pads, or more generically, fiber pads, always offer more cut on any type of tool, so just don't stay in one place for too long as you'll heat-up the paint and this can lead to burn-throughs or twisting of the paint.

With traditional wool pads, I'll tend to go-up-on edge to make controlling the rotary easier. I know some people say you should always hold the pad flat to the surface and there's nothing wrong with this, but as the pad becomes more wet with product, the pad will tend to GRAP the paint more and if you're trying to hold the pad flat you get jerked around.

When I teach boat detailing classes, it's really easy to show/teach how to go-up-on-edge because for the most part, it's impossible to hold a wool pad FLAT to the surface of a boat hull. It's pretty easy to hold a spinning wool pad flat to the surface with the fibers are dry, but once they become wet or damp with product, it's going to be a lot easier on you to buff for HOURS if you learn how to go up on edge.

Here's a couple of pictures from my recent February class. This is Veronika learning how to buff out the window frames using a wool pad on a cordless FLEX rotary polisher.

Window Frames

A tricky area to buff on any car are the window frames. The paint on the window frames looked just as bad as the paint on all the rest of the body panels. This means, in order to remove all the swirls, scratches and sanding marks, we'll need to buff these areas with the wool pad on the rotary with the Dr. Beasley's CoreCut NSP Primer.

Here's Veronika tackling the window frames like a BOSS!

If you look at the below picture you can see the guys holding the wool pads flat - so yes it can be done - especially when the wool pad is fresh/clean/DRY.

To make it easier to buff for hours, which is how long it would take a SINGLE person to buff out this large 2-door sedan, it's going to be a LOT easier to go-up-on-edge. You'll do the same type of work, that is remove deeper swirls, sanding marks, scratches, water spots and oxidation, it will just be easier on you.

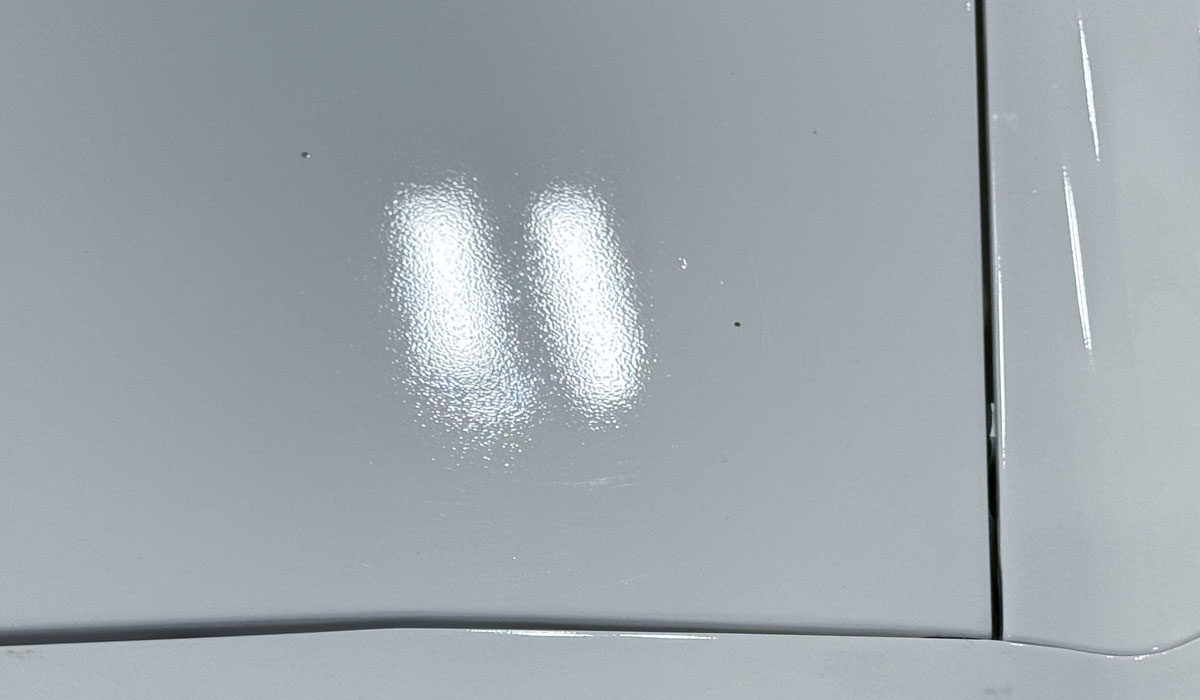

Same thing in the picture below. This person is holding the pad on edge as he buffs the concave curve of the hood panel.

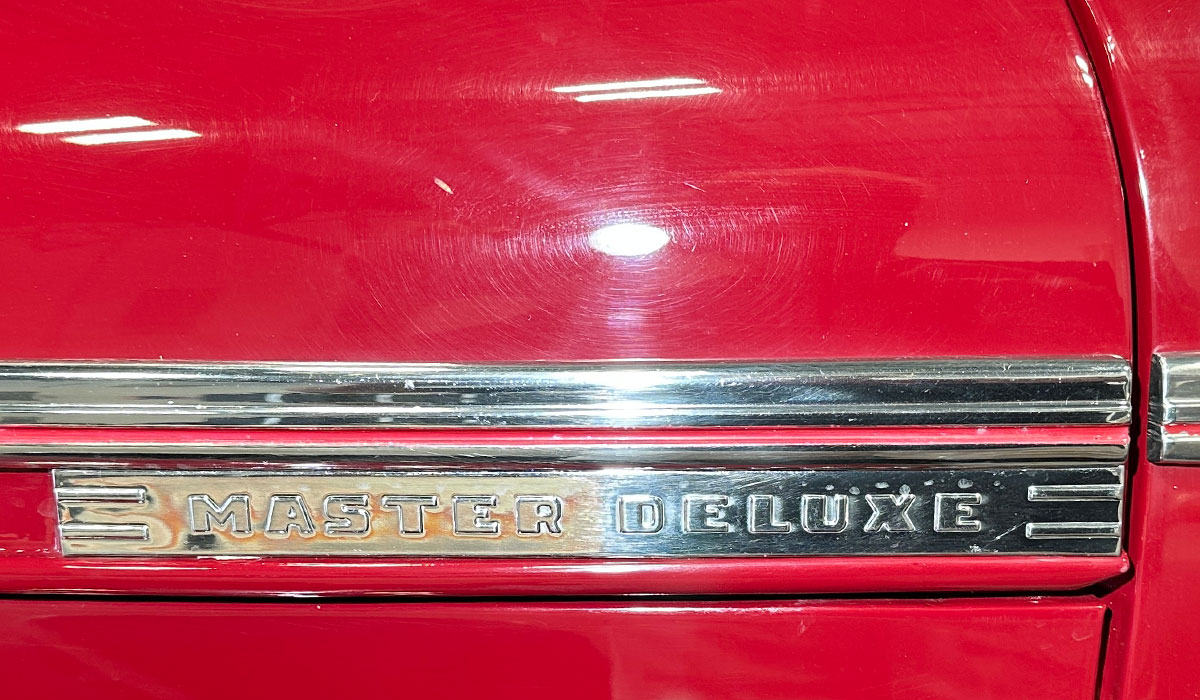

And yes, the paint on this 1941 Chevy Streetrod was in dire need of a good compounding.

The above pictures are from my recent 2-day class here in Stuart, Florida. The class starts at 7:30am sharp and after a waterless wash and claying the paint on this old 2-door Chevy, the class STARTED the first day learning how to use a rotary on some other dude's streetrod. Pretty cool.

I have another 2-day class taking place on Friday May 2nd and Saturday May 3rd at the American Muscle Car Museum in Melbourne, Florida. My co-instructor for this class will be Jason Rose and Sara Coleman-Leinhart.

I have 6 amazing training cars for this class including a 1968 Camaro and a 1962 Chevy Biscan Pro Street for the Saturday portion. On Saturday, the class will learn how to hand wet sand and machine sand these two cars, followed by using rotary polishers and orbital polishers and of course, each car will be ceramic coated.

Mike Phillips