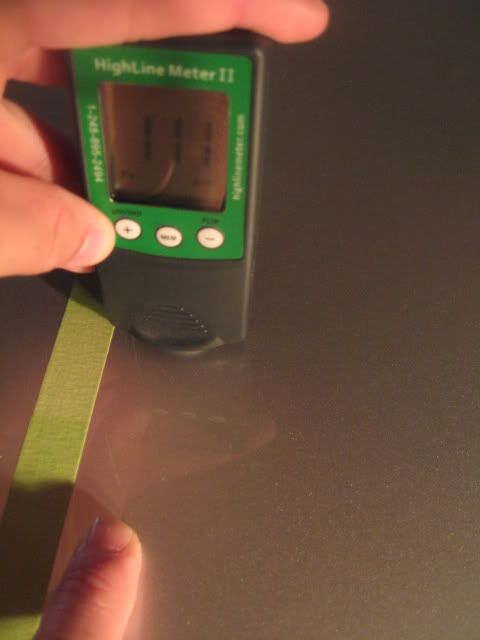

In the case of a meter like the Highline II, what you're measuring is the thickness of the entire film build -- meaning all primers, fillers/glazes, sealers, base coats, and clear coats that are sitting on top of the (ferrous metal) substrate.

It can be difficult to determine what a "good" reading is and judge how thick just the clear is, but you can sometimes guess at it by measuring the paint in the door jambs since often times these areas get less clear, if any at all applied to them from the factory.

There are however some more expensive gauges (we're talking in the $1500+ range) which can read and report how thick each layer of the film build is individually. Others (in the $2000+ range) can also read on plastic, fiberglass, carbon fiber, and other such substrates as well, though these often also require the use of a couplant (similar to the way doctors use a gel when doing an ultrasound) between the surface and the probe.

Basically what you're looking to do is to find areas you should avoid heavy sanding and/or buffing on, as well as determine how much material you're removing with whatever process you've decided to use. The goal of course being to get defects out while removing as little of the top coat as possible.