A.P.A.D.

New member

- Dec 2, 2010

- 949

- 0

I knew in the back of my mind that i would be pulling out the DW849x that i purchased a month or so ago since the clear on these Corvettes are rock solid. The polisher has been sitting in the box in the cabinet, so what better time to break it out.

the owner of the Vette did some compounding with a brillo pad(im sure that is what he said:nomore: and i believe it) on the trunk lid and wanted to get that corrected along with some water marks. i tried with a yellow CCS with M105 with the PC and it didnt even make a dent!

i knew at this point i would have to pull out the rotary. and boy was i nervous! i used rotaries before when i attended AG's detailing 101/102 in Jan of last year but i was more concerned about handling the DA polishers at the time.

i used the DeWalt with LC foamed wool pad with M105. I set it between 1000 and 1400 rpm and would keep the polisher moving at all time often times "feathering" the trigger. Then followed that with Orange CCS with M105 with the PC, then White CCS with M205 with the PC. turned out about 80% correction. LSP DG111

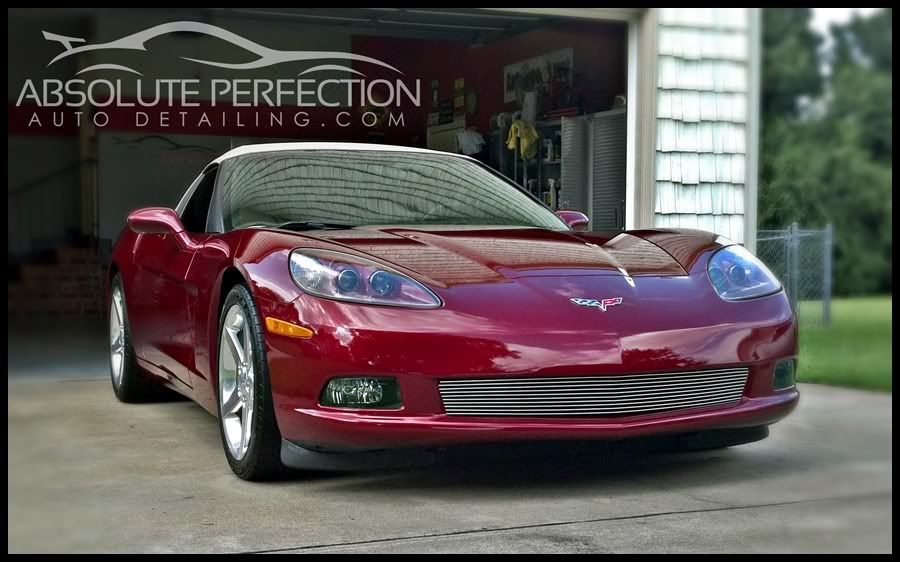

here is a pic of the car. photos were taken with camera phone so sorry for the poor quality.

I'm trying to get the guy who helps me to email me pictures he took(also on a camera phone, but look a lot better than my pictures) so i can post some of the correction shots, but I guess the main point of this thread is to share my first all out rotary experience and to say i was SCARED to death, but it all worked out!

the owner of the Vette did some compounding with a brillo pad(im sure that is what he said:nomore: and i believe it) on the trunk lid and wanted to get that corrected along with some water marks. i tried with a yellow CCS with M105 with the PC and it didnt even make a dent!

i knew at this point i would have to pull out the rotary. and boy was i nervous! i used rotaries before when i attended AG's detailing 101/102 in Jan of last year but i was more concerned about handling the DA polishers at the time.

i used the DeWalt with LC foamed wool pad with M105. I set it between 1000 and 1400 rpm and would keep the polisher moving at all time often times "feathering" the trigger. Then followed that with Orange CCS with M105 with the PC, then White CCS with M205 with the PC. turned out about 80% correction. LSP DG111

here is a pic of the car. photos were taken with camera phone so sorry for the poor quality.

I'm trying to get the guy who helps me to email me pictures he took(also on a camera phone, but look a lot better than my pictures) so i can post some of the correction shots, but I guess the main point of this thread is to share my first all out rotary experience and to say i was SCARED to death, but it all worked out!