MshawnBauer

New member

- Apr 18, 2013

- 203

- 0

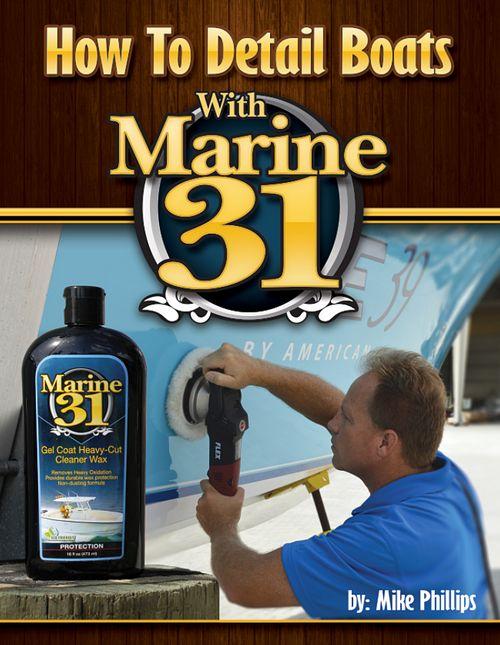

So, I did my first boat yesterday! Gel coats are NO joke! I did a basic wash followed up with a single step buff/polish and wax as a LSP. I used the Meguiars M67 one step compound with foam pads on my Rupes 21. I broke it up into sections and went to town. Two solid passes on each section with the M67/foam/Rupes gave me (although not perfect) a big noticeable difference. I finished it up with a coat of Collonite IW 845. Honestly, I love my Rupes, but I think a rotary would have been more efficient. Start to finish it took about 4.5 hours. What are you guys, that do boats on the regular, using? I would have liked faster, better cutting power but rotaries make nervous. How would a forced roatation do? Maybe the new makita or Flex? Please advise! Boats are so much different than cars, lol. Very satisfying to do, but a lot more work than I imagined! I was going to do the trailer as well (polish the wheels and dress the tires but I just ran out of time). Your input and feedback are GREATLY appreciated!

View attachment 57874

View attachment 57875

View attachment 57876

View attachment 57877

View attachment 57878

View attachment 57879

View attachment 57880

View attachment 57882

View attachment 57883

View attachment 57884

View attachment 57874

View attachment 57875

View attachment 57876

View attachment 57877

View attachment 57878

View attachment 57879

View attachment 57880

View attachment 57882

View attachment 57883

View attachment 57884