Hey Bill!

Don't think we've met just yet, but I see we have a few things in common. First, I used to own

one of those *rare* Alabama State Trooper Javelins.

Not just ANY Javelin, but mine was a 401, slap stick auto, Dana positrack,

that never had the holes drilled in the roof (

for that huge bubblegum blue light). I traded a car (

plus him giving me $100) with another guy to get the car, and it was a BEAST! It'd literally smoke the tires till you let off the gas. (

Especially on those old 70 series bias ply tires.)

After I got it I had a car salesman call me for 6 months wanting to buy it.... finally caved in and sold it for a $1500 profit (which was HUGE in the mid 70's). I didn't realize at the time just HOW RARE it was, it was just another car to me (had 3 and 2 bikes and still living at home).

Then he sold it to a collector in NJ (I'm and Atlanta boy all my life)

and he made $2500 profit on it! Fast forward 30 years and I caught one at a Barrett Jackson auction (I think),

while they went on and on about how rare it was, especially being it wasn't a "patrol" car... and then it went on to bring well over $200K! :dunno:

The other thing we have in common is I owned a flatbed (only) towing business for 18 years. (

No city/county work, specialized in hi-line, dealership and insurance company work mainly.)

And lastly... we've both been using Meguiar's stuff since the "old days". :laughing:

But you didn't come here to talk about past lives I'm sure.

As the heat rises our good ol' 105 gets harder and harder to work with. Honestly... since 101 came out I really don't use 105 anymore. Mixing it with UC is the first thing that comes to mind.

First you need to make sure you're properly priming your pad. Assuming that is done correctly there are several options to get the most from 105.

If you go get some Megs Ultimate Compound and prime your pad with that, or at least mixed 50/50 with 105 that'll help a TON. Once the pad is primed you can then say use 2 dollops of 105 and 1 of UC. No big secret that UC will work much longer, but the cool part is it has almost as much cut as 105. I'd say if 105 has a "10 cut" that UC is an "8".

Another thing that works well is mineral oil, (baby oil is what I use). Don't need a huge bottle either as just a small drop works. I keep a small bottle on my cart, I dunno' about 5" tall or so. :dunno: You can take your finger and put a little on your pad and try that.

Also, once 105 is stuck on the paint (as you've found out) it is like freaking CEMENT! Take a little UC, and/or some of the mineral oil and rub it around on the dried/crusty 105 and do a quick working into the surface with your Flex on a low speed and it should remove fairly easily.

That's the easy way.

Of course you ALWAYS want to keep a spray bottle of distilled water on your cart as well. If the product is drying out, mist your pad, as well as the surface. Hit it ONE pass and wipe it off. The thing with 105 is it cuts so darned hard that it'll pick up abraded paint and dirt/contaminates on the first pass and by the time you go over it twice it really starts to dry out with that spent product building up both on the surface and in your pad.

Funny you posted this today though. I just got off the phone with Nick and was discussing how I really tried over the last 2+ years to try and move towards using only SMAT based products. I liked the idea that they cut hard, cut the first time, second time, and each and every time just like when you started. The problem is (as you know) the working time is something a bit different. Whilst the product will cut for as many passes as you care to use it, the WORKING TIME is shorter than the cutting time.

FWIW, you'd be well off to do 2 section passes, 3 tops and remove it. In cold weather it'll work longer, but the hotter it gets the quicker you need to remove it. It needs to be removed wet. Not 'wet wet' but as you can still see the film, and it'll still wipe with your finger it needs to be removed. It does NOT need to be "worked down" (

which leads to more trouble than it's worth) like a DAT product (

which always needs to be worked down).

But guess what?

In the order I did last night (

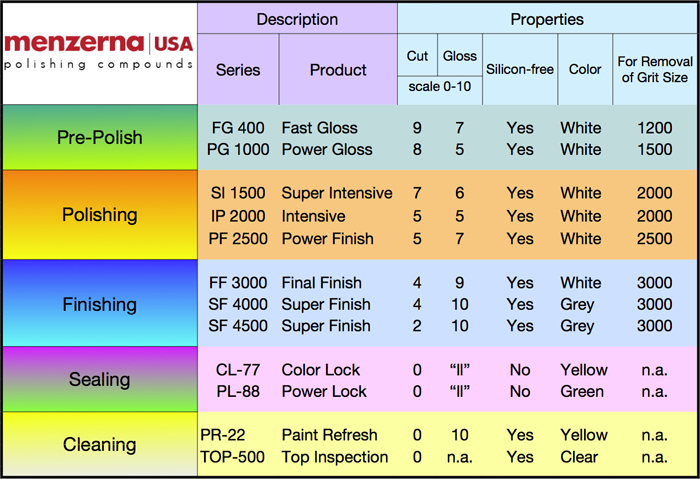

and was talking to Nick about today) nothing but MORE Menzerna products. You want something that'll cut, right? Get FG400!!!!! I am still using Megs SMAT products for my heavy cutting (

even 101 which is friggin' AWESOME, will work as long as you care to whenever you care to... and well worth the high price any day of the week) but have ended up using Menz 1000, 2500 & 4000 for where I needed to "finish down" on paints that were not rock hard, or where I wanted something that just made it easier for others around here to work with. (

As in I don't have to look over their shoulders.)

Then I finally got some FG400. WOW! It really cuts (

at least that first couple of passes) but what is amazing is that it'll finish down with a gloss that just doesn't seem possible.

rops: Now I've got 400, 1000, 1500, 2500, 4000 & Sealing Wax.!

Seemed weird at first, when you look at the Menzerna chart. What with all the different cuts (which I get) but the overlapping gloss factors where one has more cut AND MORE GLOSS then another has less cut and less gloss. Seemed a bit redundant (and is actually) but if you study the chart you'll see why I skipped SI-1500 and went with 1000 and 2500. :dblthumb2:

Although SI-1500 is probably the most popular product that guys use for AIO/single stage buffing processes. It will finish down pretty darned good. Just do 4~5 section passes at higher speed, pull the pad away and spritz it ever so slightly with water, slow the machine speed down a notch and speed up the arm speed just a hair and do 3~4 more section passes. You'll like it! (

FWIW that works with every Menzerna product.)

The trick (with Menzerna, AND Meguiar's as well) is your pad selection. It's very possible to start with one pad for added cut, then finish with another with little to zero cut and you can end up getting what looks like a 2-step process with only a single compound/polish.

I'll still be tried and true a Meguiar's guy till the end, but I've found that even in these days of excellent SMAT products that the room in my inventory where I tried to remove those old school DAT products not only didn't get smaller, but has actually INCREASED over the years. :laughing:

That being said, there are a lot of exciting things being said for the 3D/HD products as of late. Those are SMAT based (although it may be argued that "HD Adapt" is a hybrid). I've not tried it yet, but really want to.

Uhhhhh should someone want to reach out to me and send me a sample of HD Adapt I'd surely not complain.