Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 8

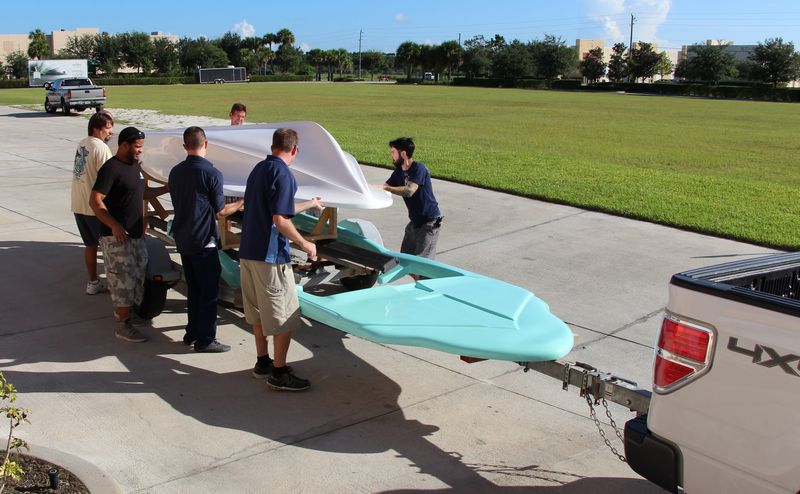

Pictures: 1960 Glastron Wetsanding Class - September, 2014 Ship Shape TV

From September of 2014

This project was featured on Ship Shape TV

First, here's some pictures that show the excessive orange peel or surface texture in the gel-coat after it was sprayed as a part of restoring this classic Glastron.

Not there is zero gloss or shine in the gel-coat finish...

Frame-up shot

I'm take a far show of the corner so you can see what I'm photographing...

Close-up of the above shot...

Extreme close-up of the above shot --> Notice the rough texture? This will all have to be sanded FLAT.

These are the overhead florescent lights....

Notice how hard it is to SEE the florescent lights reflecting off the bow of the boat?

This is due to the rough, pebbled texture of the freshly sprayed gel-coat. This is NORMAL and this is why fresh gel-coat MUST be sanded and buffed to create a beautiful looking finish on the boat. There's basically ZERO reflection of the lights overhead.

Here's the hull before we started....

This too will have to be sanded till the surface is flat....

Here's the finished results....

I took these shots the next morning, both the top cap and the hull had been sanded, compounded, polished and waxed....

Now let's take a look at how this project rolled out....

From September of 2014

This project was featured on Ship Shape TV

First, here's some pictures that show the excessive orange peel or surface texture in the gel-coat after it was sprayed as a part of restoring this classic Glastron.

Not there is zero gloss or shine in the gel-coat finish...

Frame-up shot

I'm take a far show of the corner so you can see what I'm photographing...

Close-up of the above shot...

Extreme close-up of the above shot --> Notice the rough texture? This will all have to be sanded FLAT.

These are the overhead florescent lights....

Notice how hard it is to SEE the florescent lights reflecting off the bow of the boat?

This is due to the rough, pebbled texture of the freshly sprayed gel-coat. This is NORMAL and this is why fresh gel-coat MUST be sanded and buffed to create a beautiful looking finish on the boat. There's basically ZERO reflection of the lights overhead.

Here's the hull before we started....

This too will have to be sanded till the surface is flat....

Here's the finished results....

I took these shots the next morning, both the top cap and the hull had been sanded, compounded, polished and waxed....

Now let's take a look at how this project rolled out....