PrismDetailing

New member

- Feb 25, 2014

- 190

- 0

I was recommended to this customer when he was looking to have his Audi RS4 corrected. The customer had recently purchased the car, so really i was asked to remove the swirls and bring some bling back to the paintwork again.

When the car turned up:

The car was rined, then snowfoamed:

rinsed and the alloys were cleaned:

washed with Nanotech Shampoo then the decontaminiation stage consisting of Tardis, Iron Cut and claying:

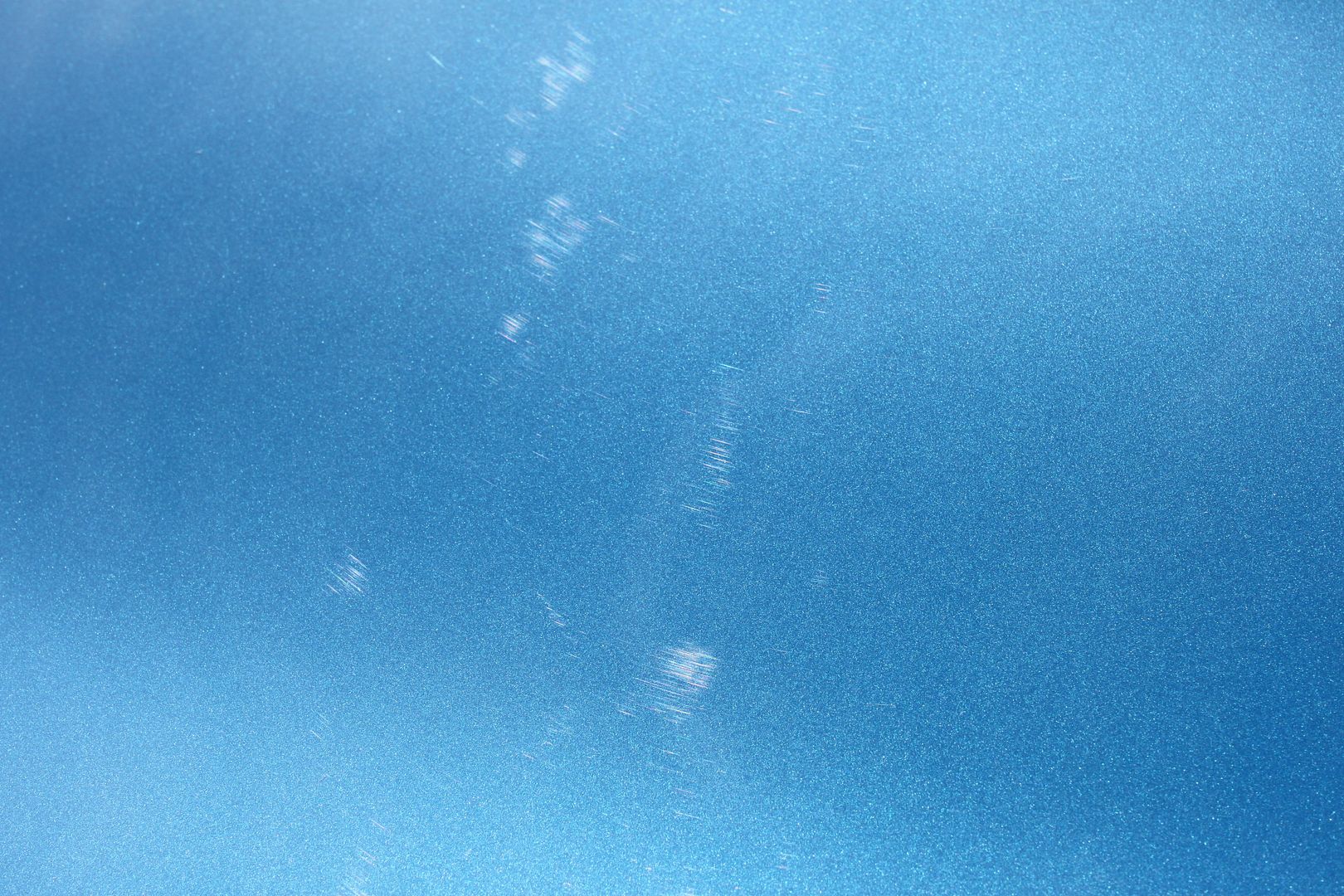

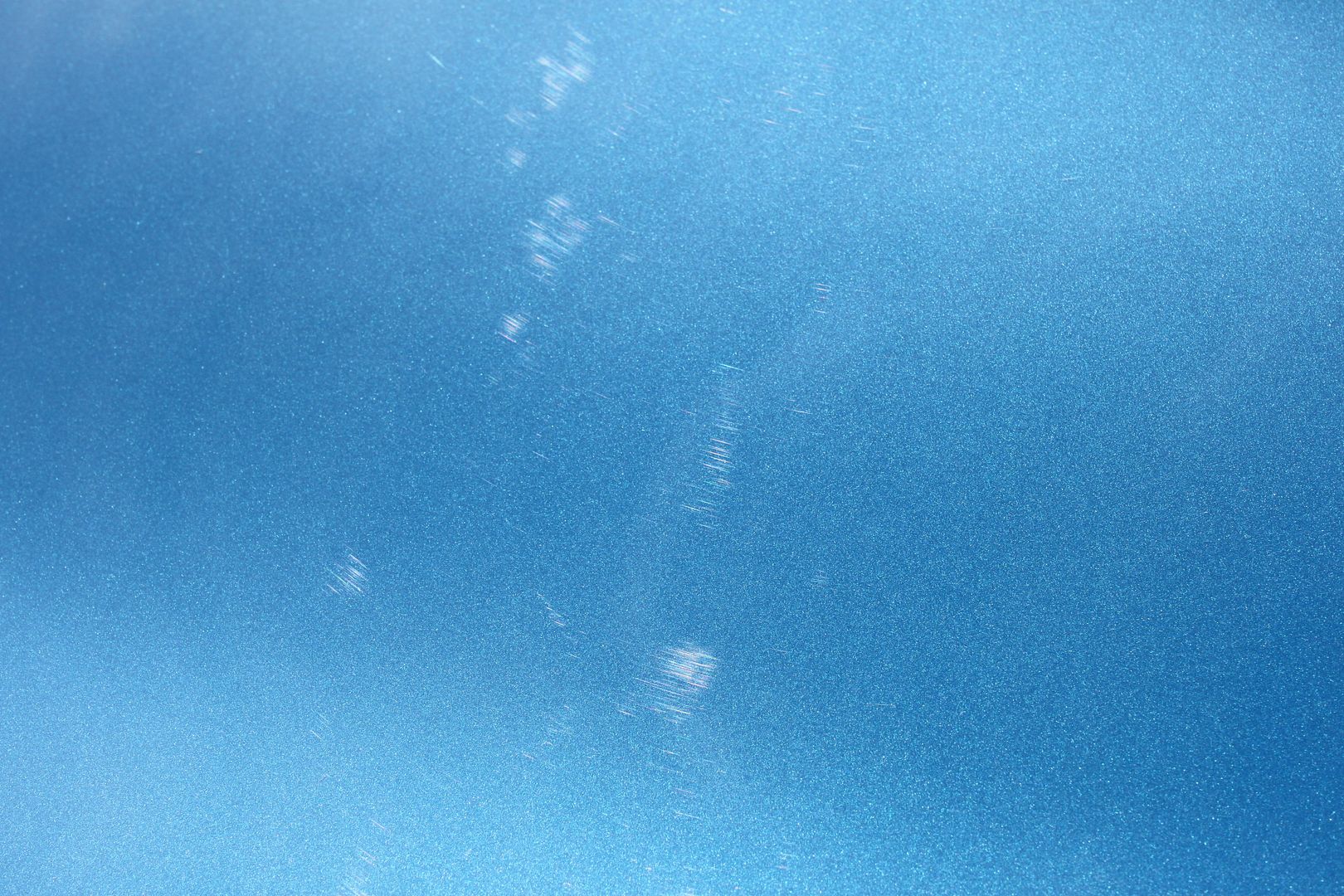

Then i rewashed, rinsed and dried with a Dodo Juice Supernatural Towel....moved onto the inspection of the paintwork and determining what needed done:

Using Scholls Concept S17+ for a majority and in some cases moving to S3 Gold and finally refining with S40, correction was achieved:

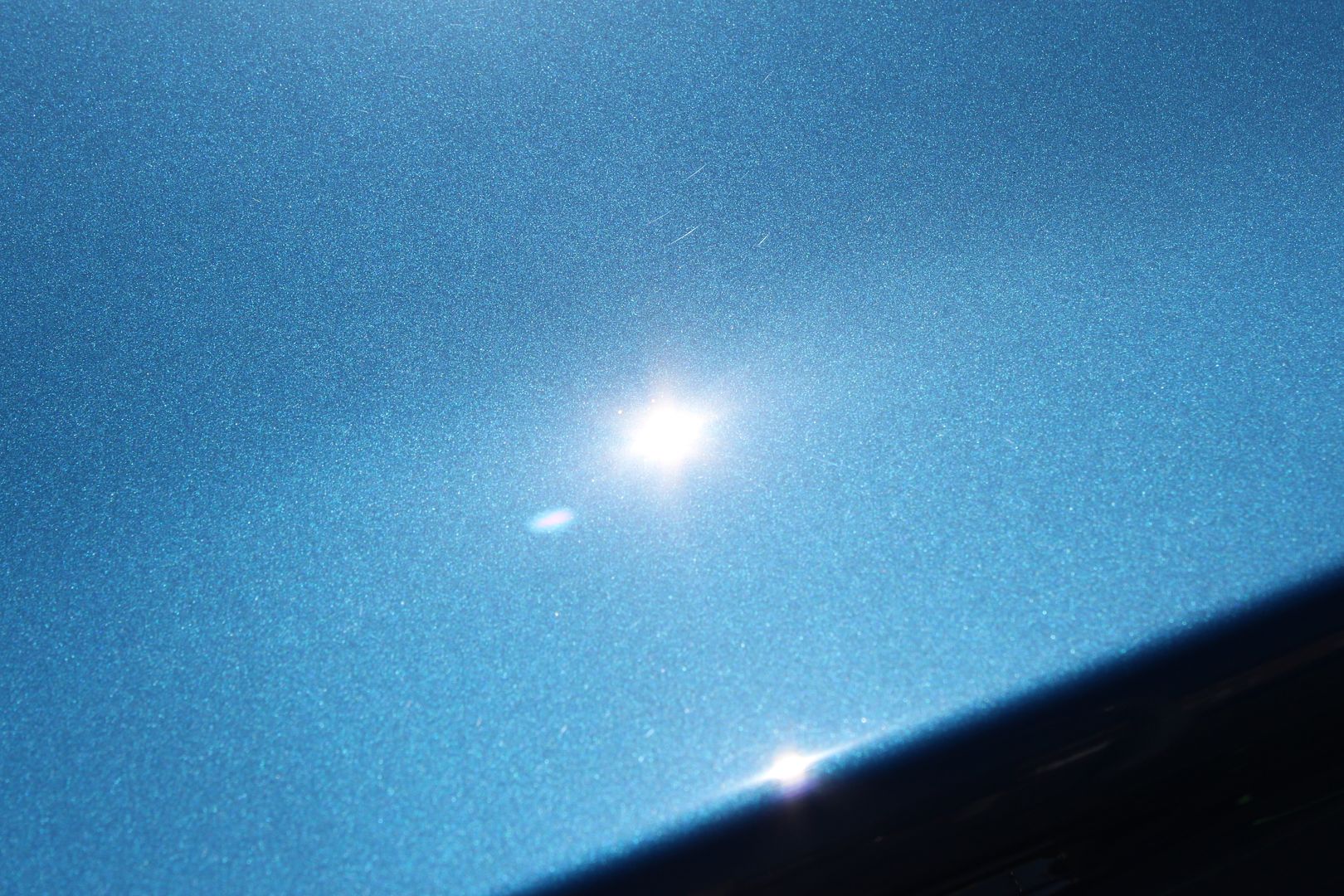

50/50:

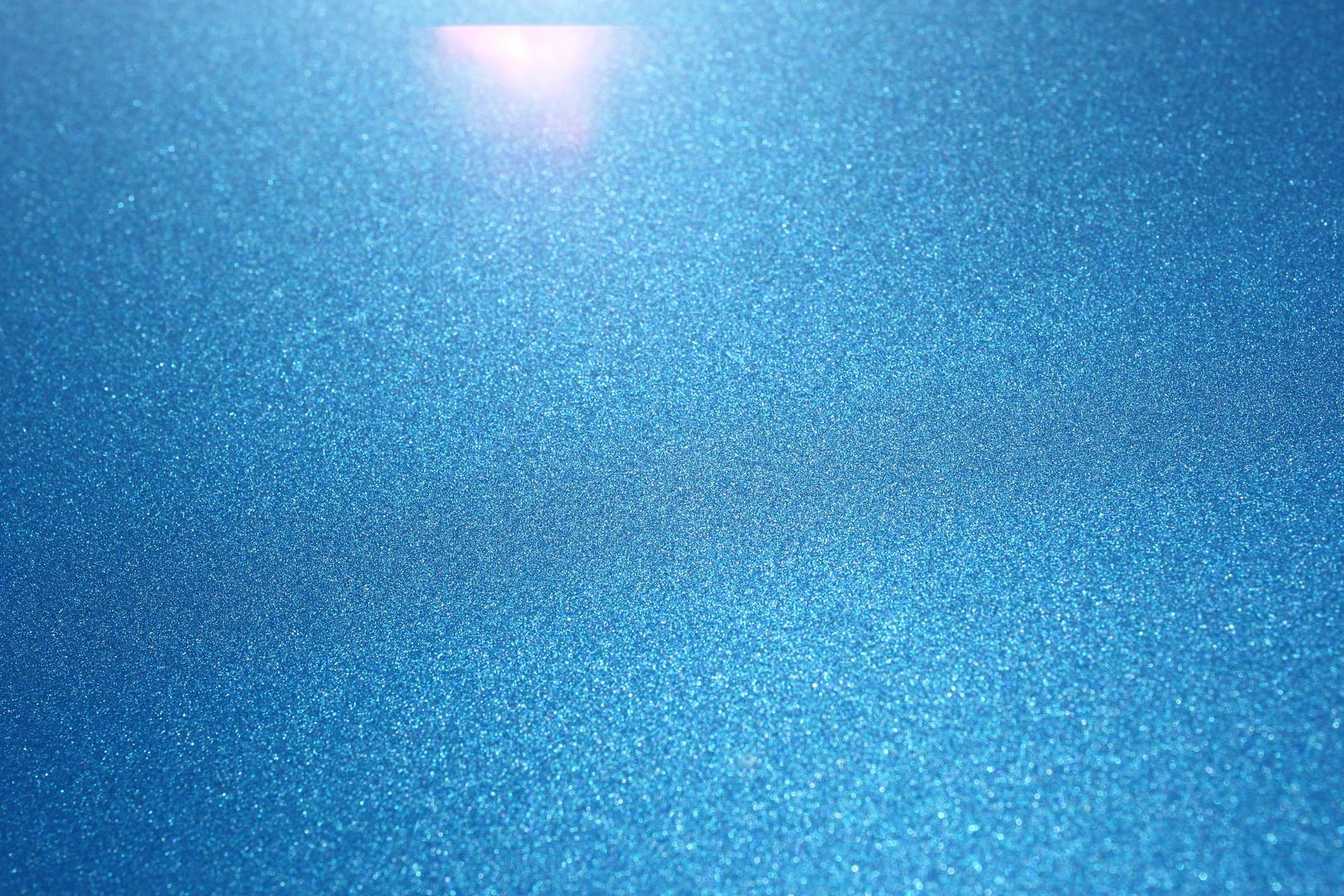

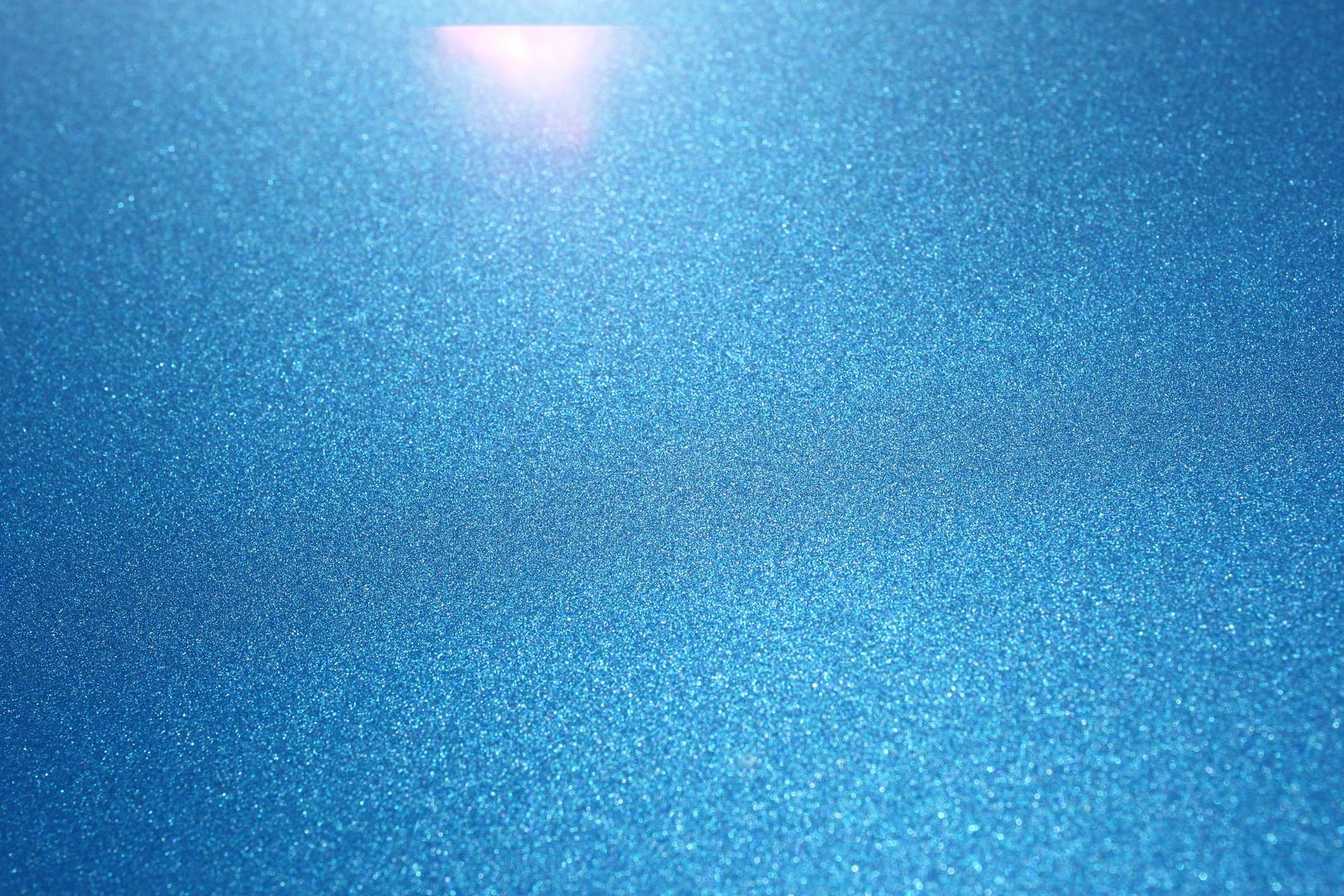

Corrected:

The paintwork was protected using Swissvax Shield, Glass with Permanon Glass (exterior) and Dodo Juice Clearly Menthol (interior), alloys were protected with Swissvax Autobahn and tyres dressed with Swissvax Pneu. All the trim was treated to Swissvax Nano Express and the rubbers to Seal Feed. The interior trim treated to Swissvax Quick Interior Finish and the leather to LTT products. Enine bay treated to Chemical Guys Silk Shine Dressing, Exhaust to Swissvax Metal Polish (noticed this had been worked previously!!!) the end results:

and finally a little walk round video, highlighting the gloss which pictures cant show moving over the curves of the car:

[ame=http://www.youtube.com/watch?v=_OLPjpDKSXo]Audi RS4 Full Correction Detail (Swissvax) by Prism Detailing - YouTube[/video]

Thanks for viewing

Rob @ Prism Detailing

Prism Detailing - Car Detailing Specialist

info@prismdetailing

FB: PrismDetailingUK

When the car turned up:

The car was rined, then snowfoamed:

rinsed and the alloys were cleaned:

washed with Nanotech Shampoo then the decontaminiation stage consisting of Tardis, Iron Cut and claying:

Then i rewashed, rinsed and dried with a Dodo Juice Supernatural Towel....moved onto the inspection of the paintwork and determining what needed done:

Using Scholls Concept S17+ for a majority and in some cases moving to S3 Gold and finally refining with S40, correction was achieved:

50/50:

Corrected:

The paintwork was protected using Swissvax Shield, Glass with Permanon Glass (exterior) and Dodo Juice Clearly Menthol (interior), alloys were protected with Swissvax Autobahn and tyres dressed with Swissvax Pneu. All the trim was treated to Swissvax Nano Express and the rubbers to Seal Feed. The interior trim treated to Swissvax Quick Interior Finish and the leather to LTT products. Enine bay treated to Chemical Guys Silk Shine Dressing, Exhaust to Swissvax Metal Polish (noticed this had been worked previously!!!) the end results:

and finally a little walk round video, highlighting the gloss which pictures cant show moving over the curves of the car:

[ame=http://www.youtube.com/watch?v=_OLPjpDKSXo]Audi RS4 Full Correction Detail (Swissvax) by Prism Detailing - YouTube[/video]

Thanks for viewing

Rob @ Prism Detailing

Prism Detailing - Car Detailing Specialist

info@prismdetailing

FB: PrismDetailingUK