4u2nvinmtl

New member

- Jun 9, 2015

- 443

- 0

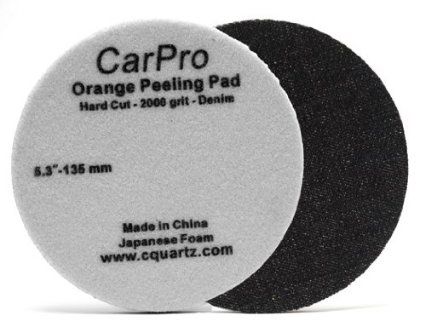

CarPro Denim Orange Peel Removal Pads

After detailing my silver 09 Jeep SRT8 for about a year the orange peel really started to get to me. At first I thought my only option was to have the entire Jeep wet sanded but after a few more Google searches I came across these pads. Once I saw Mike Phillips post about how to remove Orange Peel using a PC-7424xp and these pads I was committed to try for myself.

Processes:

Notes:

Impressions:

FAQ’s:

Other details:

Post Orange Peel paint thickness results (in microns):

Pictures:

After detailing my silver 09 Jeep SRT8 for about a year the orange peel really started to get to me. At first I thought my only option was to have the entire Jeep wet sanded but after a few more Google searches I came across these pads. Once I saw Mike Phillips post about how to remove Orange Peel using a PC-7424xp and these pads I was committed to try for myself.

Processes:

Each week I 2 bucket washed the whole Jeep and fully decontaminated just one panel. I chose to work one panel per week as not to rush the process and to get the results I wanted. I used M101 with 5.3inch and 4inch CarPro Denim Orange Peel Removal Pads using a PC-7424xp on speeds 5 and 6. I primed the pads by using one or two sprits of quick detail spray and four pea-sized dots of M101, once the pad was primed I only added 2-3 drops of M101 as needed. I did 3 overlapping crosshatch passes then inspected. I found 5 overlapping crosshatch passes was the sweet spot for my paint. I used 2-3 pads per panel as they get gunked up with clear/paint rather quickly. After the Orange Peel was removed (buffed flat) I went back over it with 5.5inch tangerine Hydro-Tech pads and Klasse All-In-One in order to remove any Trade Secrete Oils left behind from the M101 compound. I then applied a very thin layer of Klasse Sealant Glaze by hand using a foam applicator using the wipe on wipe off method. The following week when moving to the next panel I applied another layer of Klasse SG to the completed panel(s) layering a total of 6 times on all panels by the time I had completed.

Notes:

I did not have the paint thickness checked prior to starting I was confident it was more than thick enough. Don’t pass over any edges more than once or your will quickly cut right through the clear. My hood was made out of aluminum and the paint was significantly harder and subsequently much harder to correct and took 18-21 passes! I did not bother doing the roof or doorjambs as it’s an SUV and those parts are rarely seen.

Impressions:

The pads worked as advertised but would get clogged up quickly so you will need many pads or a good pad cleaner to do a whole car at once. The pads worked very well with M101 and the finish looked LSP ready, all though I did follow up with an m205 polish and a new LSP a month later with little to no improvement. The pads do a great job of transferring the power to the cutting surface because they are so thin, this also means they get hot very quickly and don’t absorb much product if any at all. I was quickly able to grasp how much pressure to apply when working with these pad’s and you could feel a change once they were clogged and not cutting. I also noticed that there’s a sweet spot once the pad and the compound are warmed up I would slow back down to speed 5 and let it work.

FAQ’s:

How long does it take? If anyone else plans to do this with a PC-7424, M101 and 4x Denim pads (two 5.25 inch two 4inch pads), please keep in mind it takes about 2-3 hours a panel done section by section (for me on my Jeep's paint), plus the time it takes to wash and clay/decontaminate (takes me 2-3 hours), so I typically spend around 6 hours start to finish just to do one panel, not including polishing that I did once all of the orange peel was removed from every panel.

How am I protecting/sealing the compounded panels before I polish? I’m using Klasse AIO applied by PC-7424 followed up by 6 layers of Klasse SG applied by hand (24-hour cure time, WOWO application of each layer) as winter protection until I polish.

Who taught me? I'm getting a few people asking where I learned my technique and I’ve got to say I learned it from Junkman2000 on YouTube. Junkman breaks it down in such a way that I totally understood how to buff my paint before I had even purchased my PC-7424 (never had buffed a car before)

Other details:

My Jeep SRT8 is daily driven and sees about 20,000 miles of city driving a year. I live in Montreal, Canada where there are 5 months of relentless winter weather, where the streets a riddled with potholes, roads are layered with salt, and cars are caked with rust preventing grease (including my Jeep SRT8) that eventually that leaks out all over the paint/finish and onto other cars by way of road spray.

Post Orange Peel paint thickness results (in microns):

- Hood 148-173

- Driver side front fender 132-212

- Drivers side front door (bottom) 200-280 (top) 265-303

- Drivers side back door 152-181

- Drivers side rear fender 154-180

- Passengers side front fender 212-320

- Passengers side front door 175-200

- Passengers side back door 166-200

- Passengers side back fender 154-185

- Back hatch 250-300

FYI: took 3-5 readings per panel- Driver side front fender 132-212

- Drivers side front door (bottom) 200-280 (top) 265-303

- Drivers side back door 152-181

- Drivers side rear fender 154-180

- Passengers side front fender 212-320

- Passengers side front door 175-200

- Passengers side back door 166-200

- Passengers side back fender 154-185

- Back hatch 250-300

Pictures:

Rear hatch before

Rear hatch after

Rear hatch before

Rear hatch after

Rear pillar before

Rear pillar after

Close up of the rear pillar before

Close up of the rear pillar after

Hood: Middle corrected with 18 passes, right side corrected with 10 passes, left side corrected with 3-5 passes (took this picture to show how more passes were improving the reflections and reducing the OP)

Final polish with BFWD/BFMS LSP (no filters or HDR):

At the track months later:

Rear hatch after

Rear hatch before

Rear hatch after

Rear pillar before

Rear pillar after

Close up of the rear pillar before

Close up of the rear pillar after

Hood: Middle corrected with 18 passes, right side corrected with 10 passes, left side corrected with 3-5 passes (took this picture to show how more passes were improving the reflections and reducing the OP)

Final polish with BFWD/BFMS LSP (no filters or HDR):

At the track months later: