O.C.Detailing

New member

- Jul 24, 2009

- 740

- 0

Okay, so John and I received 2-each of the redesigned Lake Country Hydro-tech pads. 1-Cyan and 1-Tangerine each for a total of 4 pads.

We were asked to test them and test them hard, so today we were asked to work on a 2000 BMW 323i Station Wagon...and it's black and SERIOUSLY messed up in reference to it's paint quality as you'll see in the pictures I post in this thread.

First and foremost, here's a short video to show how I polish using my Griot's:

[video=youtube_share;CAPN4I2Oo4o]- How to polish a car[/video]

I had to stop the video because the seal of the window I was polishing under had a bunch of water stuck under it and decided that it would release and soaked my pad, but it still shows my own personal technique when it comes to polishing with my Griot's.

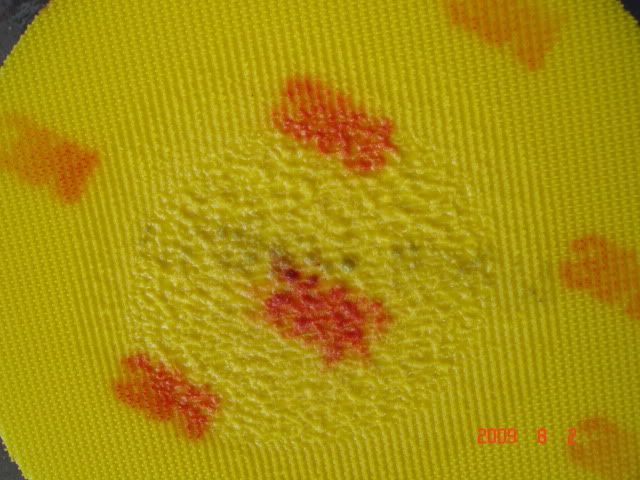

Some observations. I started with the Cyan pad. It started out very firm and correcting nicely. As I really got into polishing the car, the pad got softer and I started noticing that the center of the pad was creating a divot or indention. The center of the pad was MUCH softer than the outer edge but was NOT hot. It was warm, but no where near what I would consider HOT. This was after polishing just half of the hood, the driver's fender, driver's door and half of the rear driver's door. Here is a before and after picture of the pad:

Before:

After today's work:

Please notice the divot in the center.

At the end of the day, I had only cleaned the pad once and the picture above was taken BEFORE I cleaned the pad. The next photos are of the cyan pad after only half of the car next to an Orange 6.5" CCS pad after at least 5 cars worth of work and after I cleaned it at the end of the day so that it could be set up to dry:

So what I'll show you now are some photos of the condition of the car we worked on and a few 50/50 photos:

Here's a scratch that I had to wetsand out and a photo of that same area being buffed out:

Here's a photo of the hazing the Cyan pad left in the paint using the Griot's DA. It's hard to see, but look below the light and not exactly where the light is shining in the reflection:

Here's a before and after of half of the front fender after 1 pass of M105 on the Cyan:

Here's a 50/50 of that same fender, notice the heavy marring left by the Cyan pad as well:

Here is a 50/50 of the driver's door with marring after 2 passes of M105 on Cyan:

And here's a picture of the Cyan pad, again, after having been used on just half of the car and the wear that the pad is undergoing after just half of it's first car:

John has some close-up pictures of the pad and I'm sure he'll post them once he gets a chance.

In conclusion, the pad is wearing ENTIRELY too quickly for just having used it on half of a car. The foam appears to be breaking down VERY quickly in the center of the pad, but it doesn't seem to be affecting the correcting power of the pad. The center of the pad also seems to be tearing a little at a time and not at the edges, so at least with the backing taken to the edge of the pad, the tearing issue seems to be solved, but it's hard to say that after just the first use.

Please stay tuned for more as we break out the Tangerine pad tomorrow and show what happens after one use on that one as well.

We were asked to test them and test them hard, so today we were asked to work on a 2000 BMW 323i Station Wagon...and it's black and SERIOUSLY messed up in reference to it's paint quality as you'll see in the pictures I post in this thread.

First and foremost, here's a short video to show how I polish using my Griot's:

[video=youtube_share;CAPN4I2Oo4o]- How to polish a car[/video]

I had to stop the video because the seal of the window I was polishing under had a bunch of water stuck under it and decided that it would release and soaked my pad, but it still shows my own personal technique when it comes to polishing with my Griot's.

Some observations. I started with the Cyan pad. It started out very firm and correcting nicely. As I really got into polishing the car, the pad got softer and I started noticing that the center of the pad was creating a divot or indention. The center of the pad was MUCH softer than the outer edge but was NOT hot. It was warm, but no where near what I would consider HOT. This was after polishing just half of the hood, the driver's fender, driver's door and half of the rear driver's door. Here is a before and after picture of the pad:

Before:

After today's work:

Please notice the divot in the center.

At the end of the day, I had only cleaned the pad once and the picture above was taken BEFORE I cleaned the pad. The next photos are of the cyan pad after only half of the car next to an Orange 6.5" CCS pad after at least 5 cars worth of work and after I cleaned it at the end of the day so that it could be set up to dry:

So what I'll show you now are some photos of the condition of the car we worked on and a few 50/50 photos:

Here's a scratch that I had to wetsand out and a photo of that same area being buffed out:

Here's a photo of the hazing the Cyan pad left in the paint using the Griot's DA. It's hard to see, but look below the light and not exactly where the light is shining in the reflection:

Here's a before and after of half of the front fender after 1 pass of M105 on the Cyan:

Here's a 50/50 of that same fender, notice the heavy marring left by the Cyan pad as well:

Here is a 50/50 of the driver's door with marring after 2 passes of M105 on Cyan:

And here's a picture of the Cyan pad, again, after having been used on just half of the car and the wear that the pad is undergoing after just half of it's first car:

John has some close-up pictures of the pad and I'm sure he'll post them once he gets a chance.

In conclusion, the pad is wearing ENTIRELY too quickly for just having used it on half of a car. The foam appears to be breaking down VERY quickly in the center of the pad, but it doesn't seem to be affecting the correcting power of the pad. The center of the pad also seems to be tearing a little at a time and not at the edges, so at least with the backing taken to the edge of the pad, the tearing issue seems to be solved, but it's hard to say that after just the first use.

Please stay tuned for more as we break out the Tangerine pad tomorrow and show what happens after one use on that one as well.

Last edited: