CEE DOG

New member

- Jul 12, 2009

- 7,358

- 0

Review: CarPro CeriGlass

Product Description From AG:

Formulated with mild abrasives, CeriGlass deep cleans and polishes all glass surfaces with ease. It quickly removes acid rain spots, hard water spots, road film, stubborn bird stains, and interior glass film. CeriGlass is so effective; it even removes fine to medium scratches from glass! It leaves glass crystal clear and sparkling.

Introduction:

Until now I've never tried to polish glass with the object of actually removing scratches. I do however regularly use M105 or M205 to clean the glass when polishing a car. As you may know this works fine for cleaning the glass but paint polishes are designed to cut paint not glass, therefore they won’t remove scratches. It would be like trying to cut concrete with a plastic knife.

Until this product came along I had not had the inclination to attempt removal of scratches from glass. I considered it for my daily driver but the thought of polishing glass and the things I had read about its difficulty dissuaded me from placing it among my priorities. Not to say my windshield doesn’t seriously need to be either polished or replaced (as you will soon see).

There was a time when the last thing I ever thought about was caring for my vehicle. Years ago while in school and working a full time job my priorities consisted of working, studying, eating, and sleeping in that order. When you get 4 hours of sleep a night for an extended period of time you’re lucky if you even remember how you got from one point to another.

So back to the point! Years of not washing this poor soul allowed the sand under the wipers to drag against the glass and cause the damage at an accelerated rate. Many windshields have these types of scratches but on a lesser scale.

The chemical compound “silicone dioxide” (silica) is extremely hard and is used to make glass. In its natural state it’s found in quartz and of course sand. Therefore sand is often as hard as glass giving it the capability to leave scratches. By the time I started washing my vehicle regularly the damage was done and I lived with it… until now.

CarPros new product Ceri Glass is a water-based product, which contains no oils and utilizes the chemical compound Cerium Oxide along with other nano components.

Cerium Oxide is an off white colored powder that comes from a rare metal called Cerium. It’s used for polishing glass, polishing gemstones, and in self-cleaning ovens among other things.

Details:

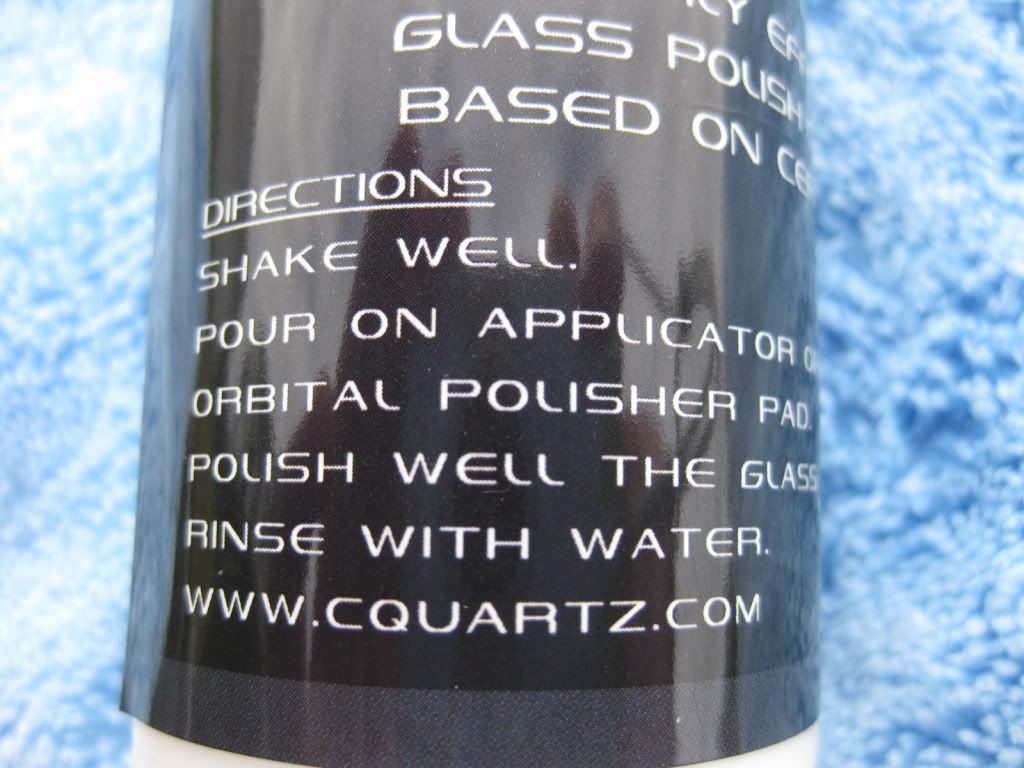

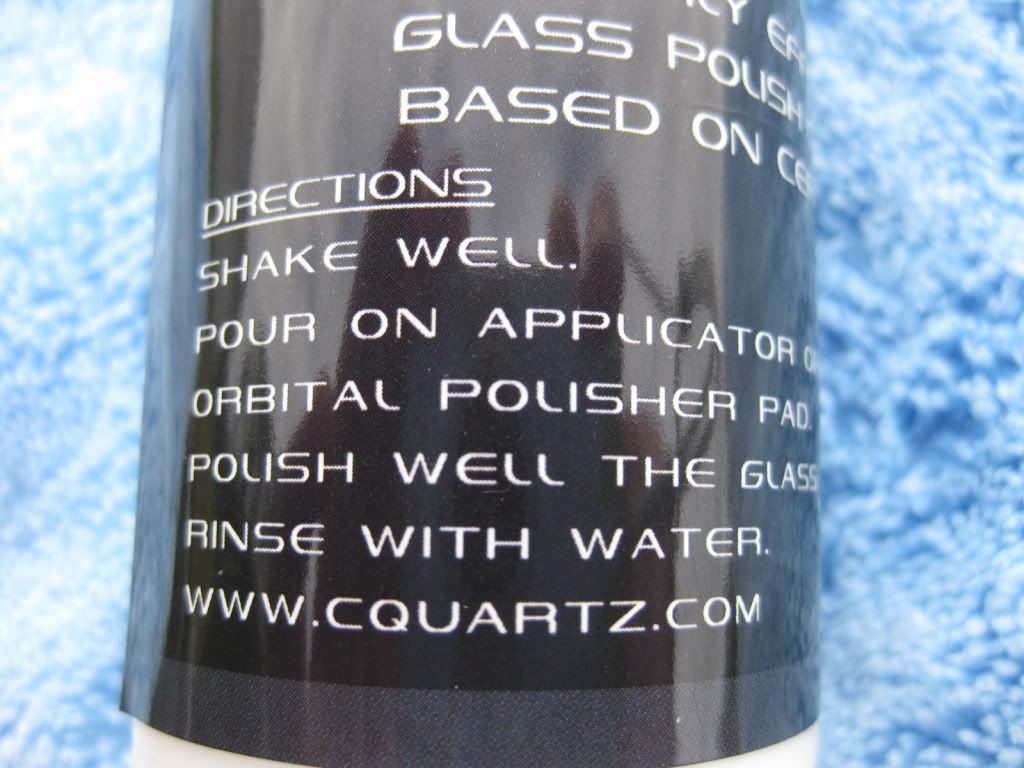

1.- Packaging: Plastic bottle with well designed applicator nozzle and screw off lid

2.- Kit Option: Contains CeriGlass, 2 hand applicators, and a CarPro terry weave mf towel

3.- Viscosity: On the thinner side for a polish

4.- Color: Off White

5.- Scent: Didn’t detect any

6A.- Intro Price: 5.1 oz. (150ml) = $8.99

6B.- Regular Price: 5.1 oz. (150ml) = $10.99

7A.- Intro Price: Kit - $11.99.

7B - Regular Price: Kit – $14.99

8.-Manufacturer: CarPro

9.-Made in: Korea

Product

Small & Precise Applicator Nozzle

Precautions:

1.- Not for use on aftermarket window tint or painted glass

2.- For best results apply in the shade on cool glass

3.- Wear a facemask to prevent inhalation of polish powder

4.- Always try a test spot first

Instructions:

1.- Cover neighboring body panels and seals to avoid dust cleanup

2.- Shake the bottle well

3.- Apply small amount on the glass polish pad or hand glass applicator

4.- Buff thoroughly in circular motion

5.- Rinse the surface, wipe with mf towel and check results

6.- Repeat if necessary

Rotary Application:

For rotary application CarPro recommends a speed between 800-1000 rpm. I didn’t know this until some time after I first used the product so this led to some exciting experimentation on my part, which leads to the beginning of my adventure with CeriGlass.

Honestly my windshield was nothing short of a hazard that I’ve lived with for far too long. You can imagine what it looked like when aimed into the sun!

This was what I started with.

Video: Before

[video=youtube_share;ME8_mDqQ2B0&feature=colike"]Before CeriGlass.wmv - YouTube[/video]

I had no glass polishing pads the first time I used CeriGlass but I was determined to give it a go so I retrieved my Flex PE-14 Rotary, a 6 1/2" Cyan HT pad and my CeriGlass. I had just finished washing all the cars so the glass was ready to be polished.

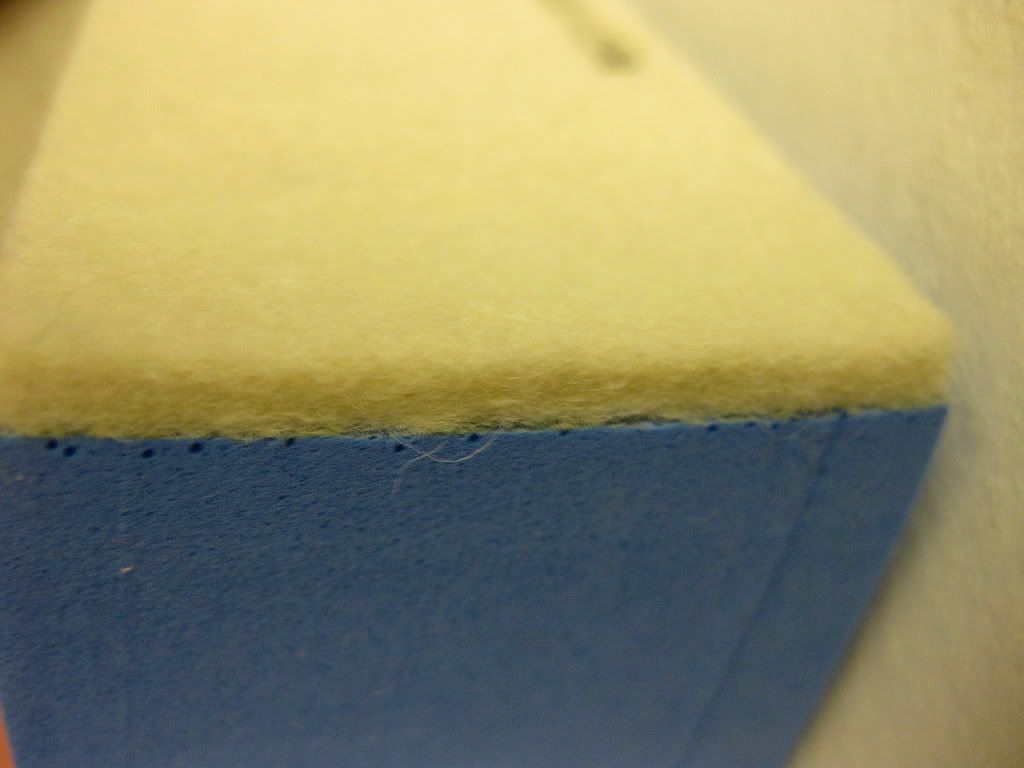

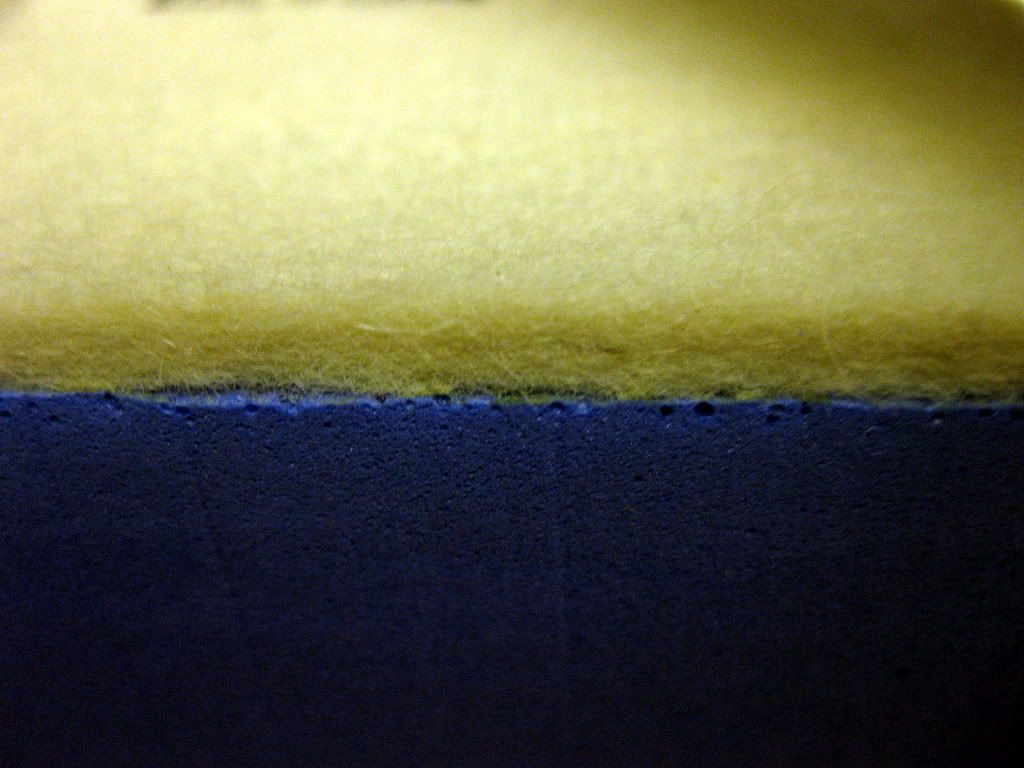

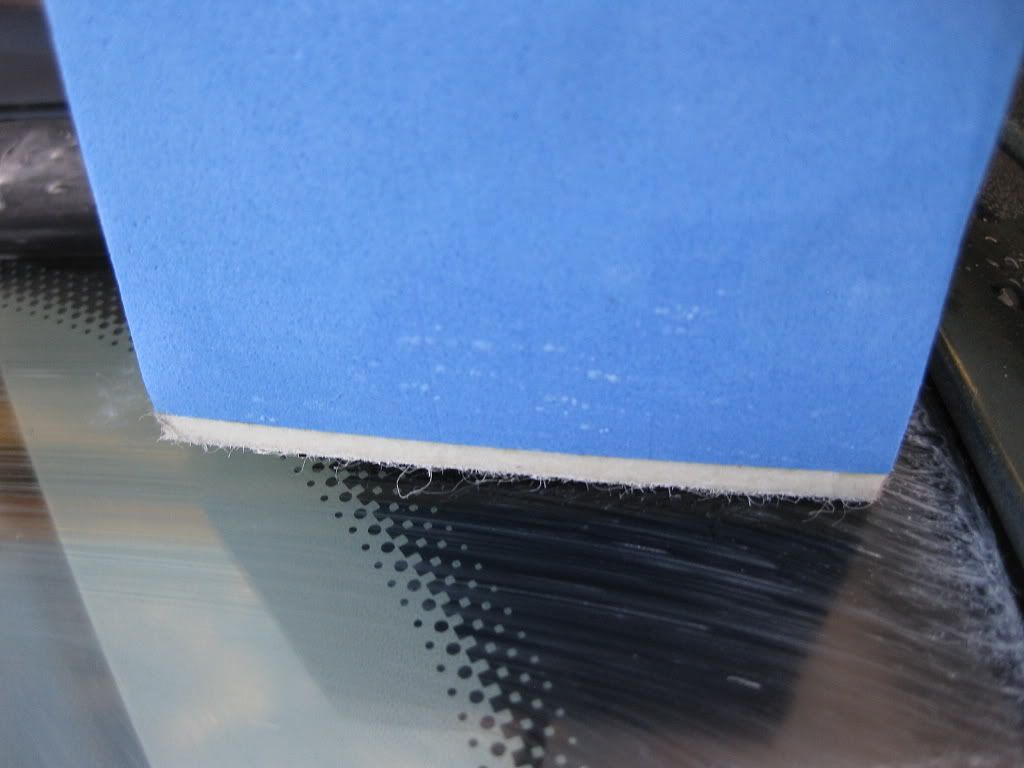

Cyan Hydrotech pad

With no knowledge of how much product to use and the logical thought that foam cannot cut glass on its own I used an ample amount of product to start with. After spreading the product across the section I bumped the speed up to about 1800 rpm. (Note: CarPro recommends 800-1000 rpm) I applied fairly heavy pressure and slowly polished the surface until the polish started to dry up. At this point I misted my pad with water from a bottle and continued until once again it began to dry up. Finally I slowed the machine to about 1500 rpm and with one more mist of water and less pressure I finished it off.

Video: Rotary and Cyan HT pad in use

[video=youtube_share;4jFEPyoiTRw&feature=colike"]CeriGlass Rotary & HT foam pad.wmv - YouTube[/video]

For cleanup I used a wet mf towel and to my surprise found a big difference in the scratches on the side of the tapeline I had polished. I believe the fact that this is closed cell foam probably made a difference in its ability to remove scratches relative to an open cell foam pad.

It did not remove the scratches completely but the huge difference made it clear to me that with additional passes that could be achieved. I also figured (at the time) that if the foam pad had done this a glass polishing pad should do even better…

While the scratches were improved by probably about 80-95% this was difficult to see in the shade. What was obvious right away was the delineation where I had polished. The glass itself looked as though it was a different color, far more clean and transparent. When I did apply light to the subject the difference in the scratches really popped out at me!

Video: Results Rotary and Cyan HT pad

[video=youtube_share;ojJRmD7wWqg&feature=colike"]CarPro Ceriglass Results 1.wmv - YouTube[/video]

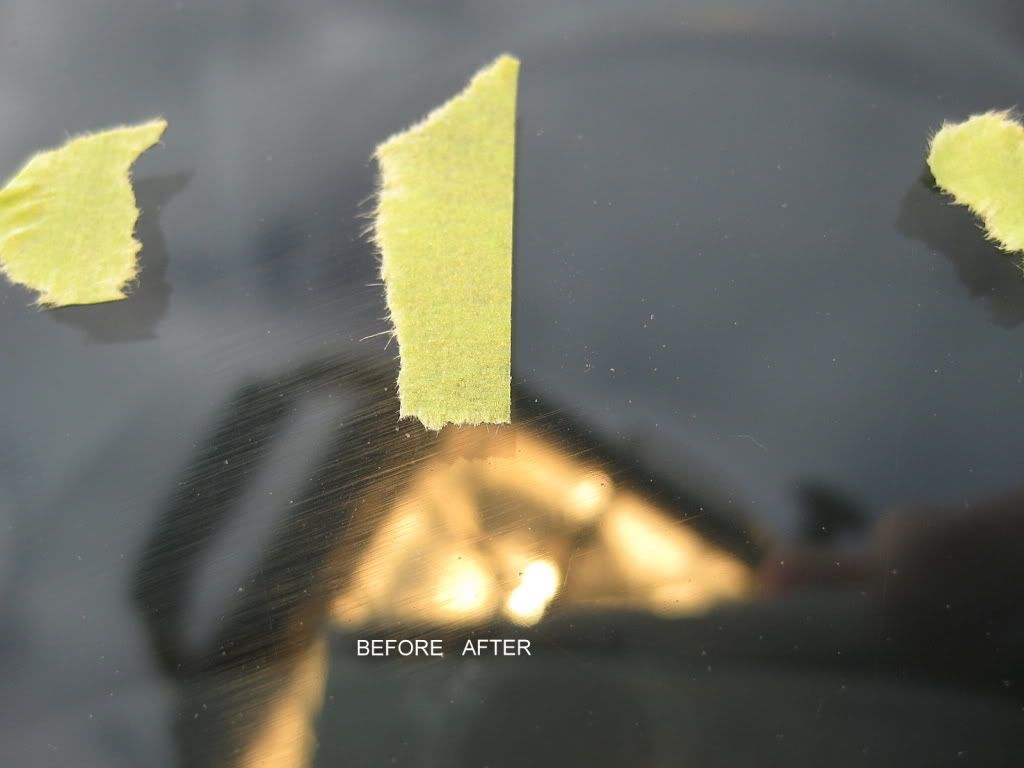

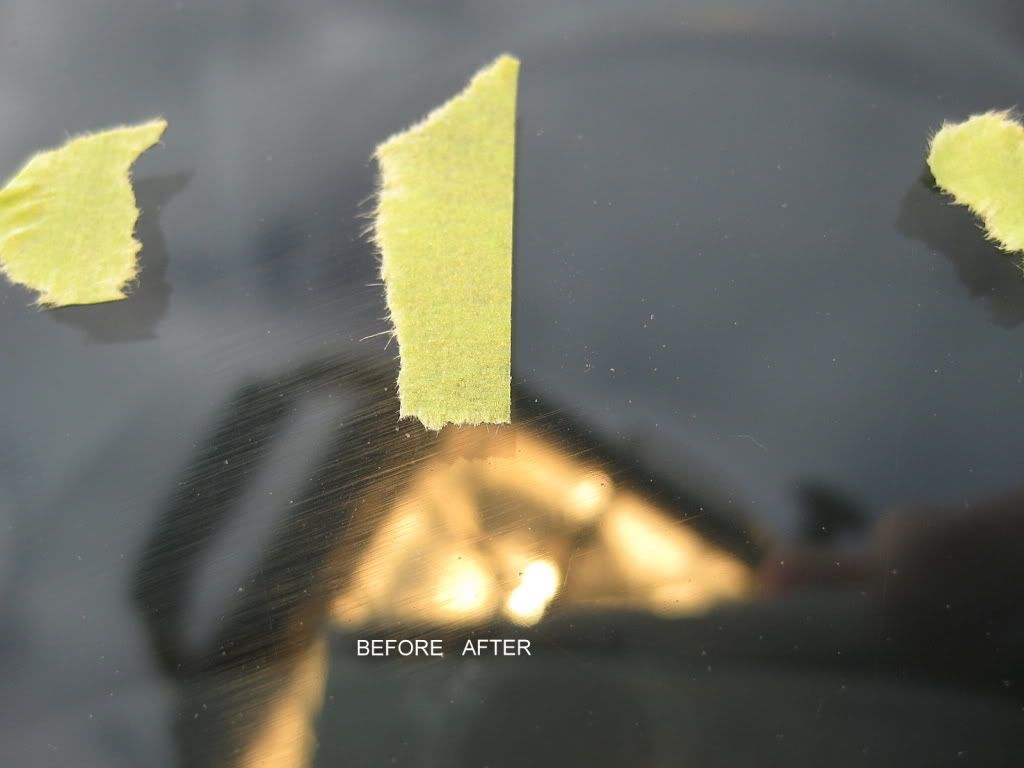

After many futile attempts at photographing the scratches I decided to wait till later to take some 50/50 photos (and the video above) when a satisfactory light source in the correct location would present itself. Here are some 50/50 photos that were taken over the following days. Please excuse any dirt and dust on the glass.

50/50

In my first go round with glass polishing I had really put an excessive amount of speed and pressure down and I had also neglected to spray water except for twice on the pad if I recall correctly. Checking the heat of the glass with my hand confirmed this. It was very hot! The heat generated by foam pads is certainly at least part of the reason CarPro recommends using a shorthaired wool pad such as this one.

CarPro mentions to rinse with water after completion of polishing. If by chance you did not follow their directions and (based on the pad, speed, and pressure you use) you end up heating the glass more than you should have I would allow the glass to cool a bit before applying a large amount of cool water to the surface. Just to note, you should not be allowing the glass to get that hot!

This brings me to an important subject which is keeping the surface of the glass as cool as possible. If you use glass polishing pads or the pads CarPro recommends heat should not be an issue but if you decide otherwise you should bring along a bottle of water to spray on the glass occasionally or as needed. In fact even with the use of the gpp which ran much cooler than foam I found a timely mist of water to be useful to keep the product from drying up and the machine running smoothly.

What you don’t want is to spray so much water that you start spinning slop all across the vehicle and yourself.

Product Description From AG:

Formulated with mild abrasives, CeriGlass deep cleans and polishes all glass surfaces with ease. It quickly removes acid rain spots, hard water spots, road film, stubborn bird stains, and interior glass film. CeriGlass is so effective; it even removes fine to medium scratches from glass! It leaves glass crystal clear and sparkling.

Introduction:

Until now I've never tried to polish glass with the object of actually removing scratches. I do however regularly use M105 or M205 to clean the glass when polishing a car. As you may know this works fine for cleaning the glass but paint polishes are designed to cut paint not glass, therefore they won’t remove scratches. It would be like trying to cut concrete with a plastic knife.

Until this product came along I had not had the inclination to attempt removal of scratches from glass. I considered it for my daily driver but the thought of polishing glass and the things I had read about its difficulty dissuaded me from placing it among my priorities. Not to say my windshield doesn’t seriously need to be either polished or replaced (as you will soon see).

There was a time when the last thing I ever thought about was caring for my vehicle. Years ago while in school and working a full time job my priorities consisted of working, studying, eating, and sleeping in that order. When you get 4 hours of sleep a night for an extended period of time you’re lucky if you even remember how you got from one point to another.

So back to the point! Years of not washing this poor soul allowed the sand under the wipers to drag against the glass and cause the damage at an accelerated rate. Many windshields have these types of scratches but on a lesser scale.

The chemical compound “silicone dioxide” (silica) is extremely hard and is used to make glass. In its natural state it’s found in quartz and of course sand. Therefore sand is often as hard as glass giving it the capability to leave scratches. By the time I started washing my vehicle regularly the damage was done and I lived with it… until now.

CarPros new product Ceri Glass is a water-based product, which contains no oils and utilizes the chemical compound Cerium Oxide along with other nano components.

Cerium Oxide is an off white colored powder that comes from a rare metal called Cerium. It’s used for polishing glass, polishing gemstones, and in self-cleaning ovens among other things.

Details:

1.- Packaging: Plastic bottle with well designed applicator nozzle and screw off lid

2.- Kit Option: Contains CeriGlass, 2 hand applicators, and a CarPro terry weave mf towel

3.- Viscosity: On the thinner side for a polish

4.- Color: Off White

5.- Scent: Didn’t detect any

6A.- Intro Price: 5.1 oz. (150ml) = $8.99

6B.- Regular Price: 5.1 oz. (150ml) = $10.99

7A.- Intro Price: Kit - $11.99.

7B - Regular Price: Kit – $14.99

8.-Manufacturer: CarPro

9.-Made in: Korea

Product

Small & Precise Applicator Nozzle

Precautions:

1.- Not for use on aftermarket window tint or painted glass

2.- For best results apply in the shade on cool glass

3.- Wear a facemask to prevent inhalation of polish powder

4.- Always try a test spot first

Instructions:

1.- Cover neighboring body panels and seals to avoid dust cleanup

2.- Shake the bottle well

3.- Apply small amount on the glass polish pad or hand glass applicator

4.- Buff thoroughly in circular motion

5.- Rinse the surface, wipe with mf towel and check results

6.- Repeat if necessary

Rotary Application:

For rotary application CarPro recommends a speed between 800-1000 rpm. I didn’t know this until some time after I first used the product so this led to some exciting experimentation on my part, which leads to the beginning of my adventure with CeriGlass.

Honestly my windshield was nothing short of a hazard that I’ve lived with for far too long. You can imagine what it looked like when aimed into the sun!

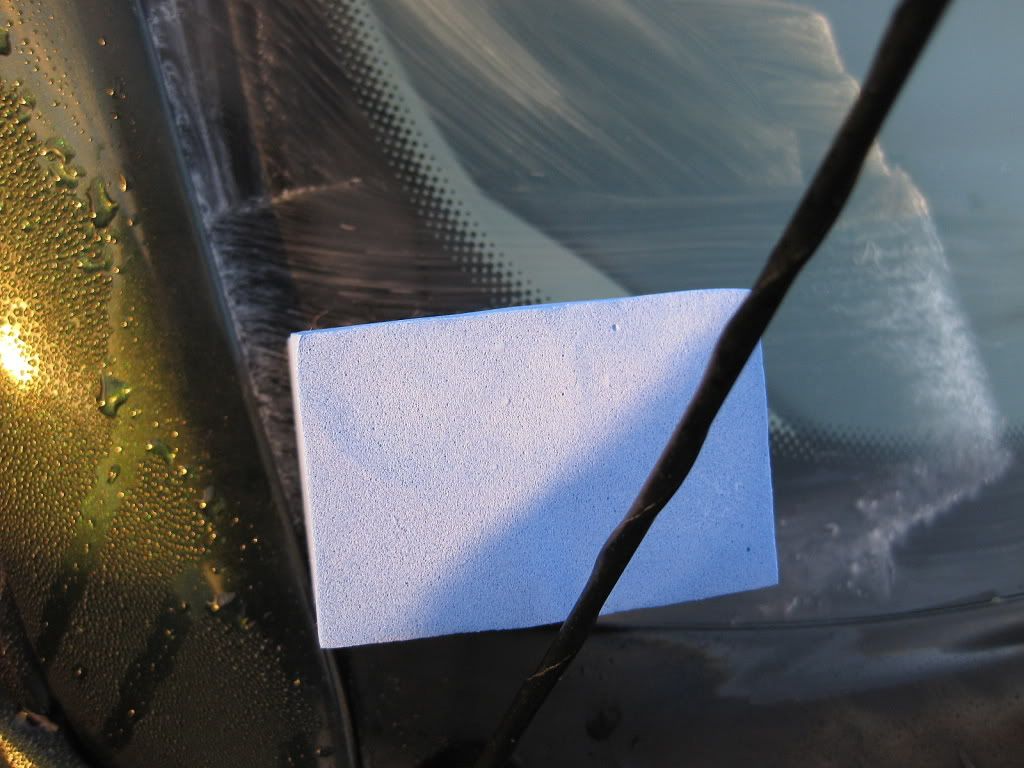

This was what I started with.

Video: Before

[video=youtube_share;ME8_mDqQ2B0&feature=colike"]Before CeriGlass.wmv - YouTube[/video]

I had no glass polishing pads the first time I used CeriGlass but I was determined to give it a go so I retrieved my Flex PE-14 Rotary, a 6 1/2" Cyan HT pad and my CeriGlass. I had just finished washing all the cars so the glass was ready to be polished.

Cyan Hydrotech pad

With no knowledge of how much product to use and the logical thought that foam cannot cut glass on its own I used an ample amount of product to start with. After spreading the product across the section I bumped the speed up to about 1800 rpm. (Note: CarPro recommends 800-1000 rpm) I applied fairly heavy pressure and slowly polished the surface until the polish started to dry up. At this point I misted my pad with water from a bottle and continued until once again it began to dry up. Finally I slowed the machine to about 1500 rpm and with one more mist of water and less pressure I finished it off.

Video: Rotary and Cyan HT pad in use

[video=youtube_share;4jFEPyoiTRw&feature=colike"]CeriGlass Rotary & HT foam pad.wmv - YouTube[/video]

For cleanup I used a wet mf towel and to my surprise found a big difference in the scratches on the side of the tapeline I had polished. I believe the fact that this is closed cell foam probably made a difference in its ability to remove scratches relative to an open cell foam pad.

It did not remove the scratches completely but the huge difference made it clear to me that with additional passes that could be achieved. I also figured (at the time) that if the foam pad had done this a glass polishing pad should do even better…

While the scratches were improved by probably about 80-95% this was difficult to see in the shade. What was obvious right away was the delineation where I had polished. The glass itself looked as though it was a different color, far more clean and transparent. When I did apply light to the subject the difference in the scratches really popped out at me!

Video: Results Rotary and Cyan HT pad

[video=youtube_share;ojJRmD7wWqg&feature=colike"]CarPro Ceriglass Results 1.wmv - YouTube[/video]

After many futile attempts at photographing the scratches I decided to wait till later to take some 50/50 photos (and the video above) when a satisfactory light source in the correct location would present itself. Here are some 50/50 photos that were taken over the following days. Please excuse any dirt and dust on the glass.

50/50

In my first go round with glass polishing I had really put an excessive amount of speed and pressure down and I had also neglected to spray water except for twice on the pad if I recall correctly. Checking the heat of the glass with my hand confirmed this. It was very hot! The heat generated by foam pads is certainly at least part of the reason CarPro recommends using a shorthaired wool pad such as this one.

CarPro mentions to rinse with water after completion of polishing. If by chance you did not follow their directions and (based on the pad, speed, and pressure you use) you end up heating the glass more than you should have I would allow the glass to cool a bit before applying a large amount of cool water to the surface. Just to note, you should not be allowing the glass to get that hot!

This brings me to an important subject which is keeping the surface of the glass as cool as possible. If you use glass polishing pads or the pads CarPro recommends heat should not be an issue but if you decide otherwise you should bring along a bottle of water to spray on the glass occasionally or as needed. In fact even with the use of the gpp which ran much cooler than foam I found a timely mist of water to be useful to keep the product from drying up and the machine running smoothly.

What you don’t want is to spray so much water that you start spinning slop all across the vehicle and yourself.