Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 6

Review: RUPES Mark III BigFoot 21 Polisher by Mike Phillips

RUPES BigFoot LHR21 MARK III Random Orbital Polisher

Used this red 2014 Corvette Stingray for a video and as a thank you to the owner, machine polished the exterior using Pinnacle Jeweling Wax. This gave me a chance to test out the new RUPES BigFoot 21 Mark III

So let's take a look at what's inside the box.

There's the polisher, a User Guide and a printout with some extra information on lubricating the backing plate where it rubs against the rubber shroud and the extension cord.

Nice. And the suggested retail price for this tool by itself is = $465.00

Now let's take a look at the features of the tool itself.

First up - it comes with a 9 meter long power cord, for we in the States that never learned the metric system this works out to be about 30 feet.

Sexy piping to make the tool look visually pleasing to any hardcore tool guy....

Extra large speed dial that's easier to read and easier to adjust.

Speed dial goes from 1 to 6

Graph imprinted on the top of the tool body shows you the OPMs for each speed setting.

Soft rubber tool rests - this one just above the speed dial.

The other tool rest is towards the front of the tool. The soft rubber tool rests enable you to lay the tool upside down without it falling over. Because the tool rests are soft rubber, if they are clean you could lay this on the hood, roof or trunk lid of a car. (I do)

Soft rubber overmold around the head of the tool makes it easier to grab and grip.

Hex Head Wrench stores onboard for removal or re-tightening of the backing plate.

Progressive Trigger provides easier control over tool speed with exact precision. (nice)

Soft rubber grip on trigger makes it easy for your finger to grip the trigger for easy speed adjustment - even if wearing gloves.

Speed lock button to lock the tool in the ON position at a determined speed setting.

Dirt and dust cover on the backing plate to keep it clean.

RUPES is not a big fan of co-mingling their system.

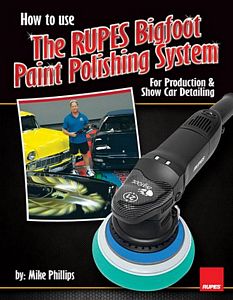

This means they prefer you to use tier pads and products with their tool. I completely understand this and back when I wrote the RUPES how-to book - if you notice the title states,

The RUPES BigFoot Paint Polishing SYSTEM

That's because it's truly a system - not just a tool.

Identification Tag - Shows it is assembled in the USA From parts made in the European Union.

The RUPES BigFoot backing plates are thin with a tapered rubber outer flange.

I strongly recommend placing a mark on the backing plate to make it easier for your eyes to watch the backing plate during operation to monitor pad rotation.

There's a lot of controversy around the practice of stuffing a spacer washer between the spindle and the backing plate. I don't do it myself as a practice but I DO apply a lubricant to the back of the backing plate to reduce friction between the backing plate and the rubber shroud. Looks like RUPE recommends the same thing.

Apply the lubricant to the blue portion of the backing plate here.

Multiple cooling holes in the backing plate align with the cooling vents on their microfiber pads.

From the Autogeek.com store page

Technical Data

• Ø backing pad mm-in - 150 – 6”

• Ø Orbit mm-in - 21 -13/16”

• Power Watt - 500

• R.P.M. - 3000 – 4500

• Weight kg-lbs - 2.7 – 5.95

• Speed regulation •

• Backing pad thread - M8

• Cord Length m-ft - 9 – 29.5

On Autogeek.net

RUPES BigFoot LHR21 MARK III Random Orbital Polisher

RUPES BigFoot LHR21 MARK III Random Orbital Polisher

Used this red 2014 Corvette Stingray for a video and as a thank you to the owner, machine polished the exterior using Pinnacle Jeweling Wax. This gave me a chance to test out the new RUPES BigFoot 21 Mark III

So let's take a look at what's inside the box.

There's the polisher, a User Guide and a printout with some extra information on lubricating the backing plate where it rubs against the rubber shroud and the extension cord.

Nice. And the suggested retail price for this tool by itself is = $465.00

Now let's take a look at the features of the tool itself.

First up - it comes with a 9 meter long power cord, for we in the States that never learned the metric system this works out to be about 30 feet.

Sexy piping to make the tool look visually pleasing to any hardcore tool guy....

Extra large speed dial that's easier to read and easier to adjust.

Speed dial goes from 1 to 6

Graph imprinted on the top of the tool body shows you the OPMs for each speed setting.

Soft rubber tool rests - this one just above the speed dial.

The other tool rest is towards the front of the tool. The soft rubber tool rests enable you to lay the tool upside down without it falling over. Because the tool rests are soft rubber, if they are clean you could lay this on the hood, roof or trunk lid of a car. (I do)

Soft rubber overmold around the head of the tool makes it easier to grab and grip.

Hex Head Wrench stores onboard for removal or re-tightening of the backing plate.

Progressive Trigger provides easier control over tool speed with exact precision. (nice)

Soft rubber grip on trigger makes it easy for your finger to grip the trigger for easy speed adjustment - even if wearing gloves.

Speed lock button to lock the tool in the ON position at a determined speed setting.

Dirt and dust cover on the backing plate to keep it clean.

RUPES is not a big fan of co-mingling their system.

This means they prefer you to use tier pads and products with their tool. I completely understand this and back when I wrote the RUPES how-to book - if you notice the title states,

The RUPES BigFoot Paint Polishing SYSTEM

That's because it's truly a system - not just a tool.

Identification Tag - Shows it is assembled in the USA From parts made in the European Union.

The RUPES BigFoot backing plates are thin with a tapered rubber outer flange.

I strongly recommend placing a mark on the backing plate to make it easier for your eyes to watch the backing plate during operation to monitor pad rotation.

There's a lot of controversy around the practice of stuffing a spacer washer between the spindle and the backing plate. I don't do it myself as a practice but I DO apply a lubricant to the back of the backing plate to reduce friction between the backing plate and the rubber shroud. Looks like RUPE recommends the same thing.

Apply the lubricant to the blue portion of the backing plate here.

Multiple cooling holes in the backing plate align with the cooling vents on their microfiber pads.

From the Autogeek.com store page

Technical Data

• Ø backing pad mm-in - 150 – 6”

• Ø Orbit mm-in - 21 -13/16”

• Power Watt - 500

• R.P.M. - 3000 – 4500

• Weight kg-lbs - 2.7 – 5.95

• Speed regulation •

• Backing pad thread - M8

• Cord Length m-ft - 9 – 29.5

On Autogeek.net

RUPES BigFoot LHR21 MARK III Random Orbital Polisher