I'm glad I stumbled on this thread. Found myself in quite a pickle today. While working on a black ZL-1 with minor swirls but some nice scratches, I started off using the M105 and an orange LC CCS pad on my Flex 3401.

The swirls and most of the scratches were gone within one pass and all that was left was the typical marring that 105 tends to leave behind.

Put a brand new white pad on the Flex and started with the 205, and it was barely making a difference. Hardly any marring was being corrected even after three passes on various speeds and pressure applications. I was getting worried.

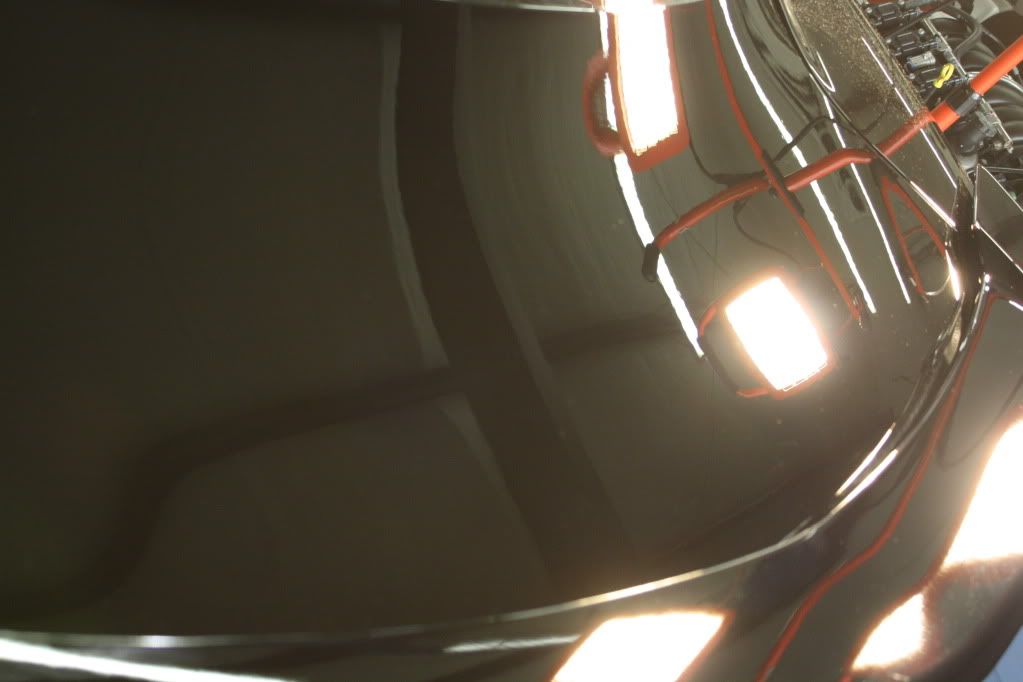

As a last-ditch attempt before re-doing the whole car with 105 and a white pad to decrease marring so 205 could do its job, I tried an LC VC pad and 205 on my Makita 9227C and it worked, but left the typical buffer trails. Hindered by time limitations, I needed a solution that would leave the paint ready for LSP as my next step. I slapped on the white CCS pad I was using on the Flex to the rotary backing plate, and BAM! I suddenly found myself not only removing the marring from the 105, but it was actually jeweling the paint in the process without any trails. A plus side was that it was working in about 2/3rds the time that it would have taken me to accomplish this with the Flex.

Moral of the story is, without my Flex, I could have potentially been too hard on the clear while removing minor scratches and squirrels. Without my rotary, the job would have been done and done well, but would have taken a lot more time for me to do it.

So the question I pose to all of the "DA or die" folks is, without working knowledge of how to use a rotary buffer, how do you know that you are not missing out on some great time saving and problem solving opportunities as a detailer? Why write off a great machine that you may not use on every car, but can save your butt when its in a sling?

The rotary is not dead. Its just not the cool kid anymore.