pampos

New member

- Mar 14, 2008

- 613

- 0

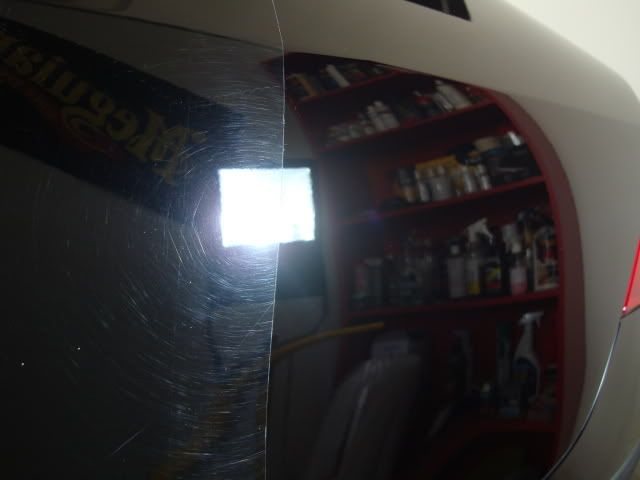

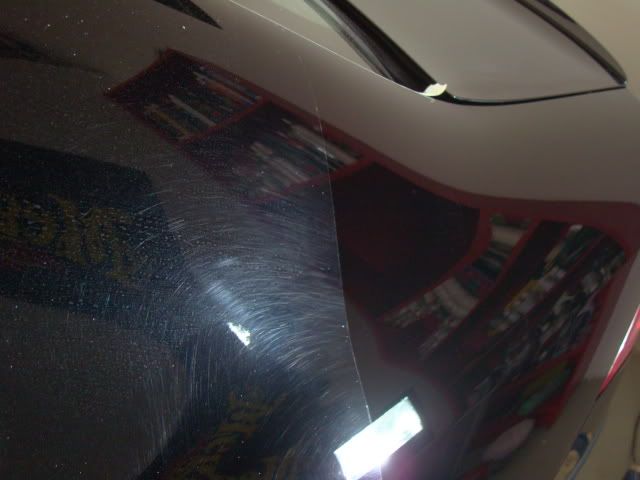

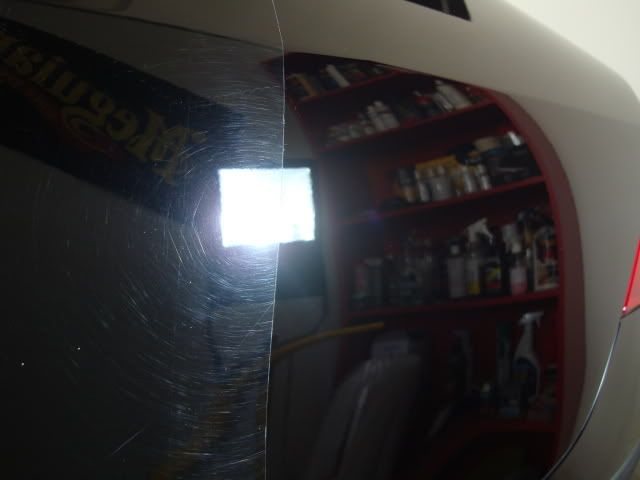

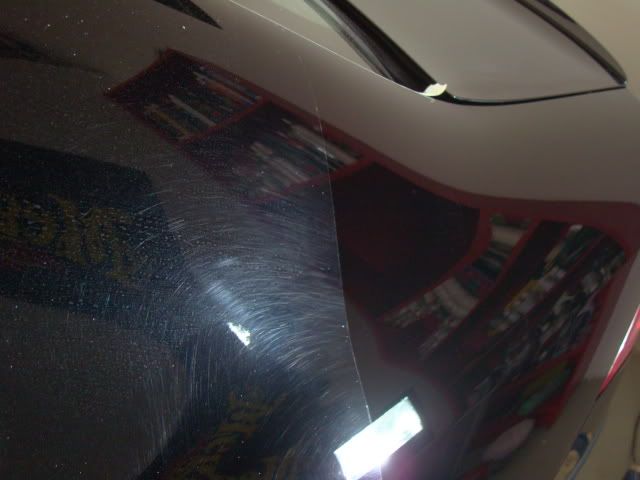

The car was full of swirl marks, RIDS and some deep scratches.

The process was

Mother's clay bar

M105 on 5,5'' LC Green heavy polishing pad with UDM

Menzerna 85RD on 5,5'' LC Black fishing pad with UDM

Sonus paintwork clearness on 5,5'' LC Blue pad with UDM

Nanolex basic paint sealant

Some before pictures

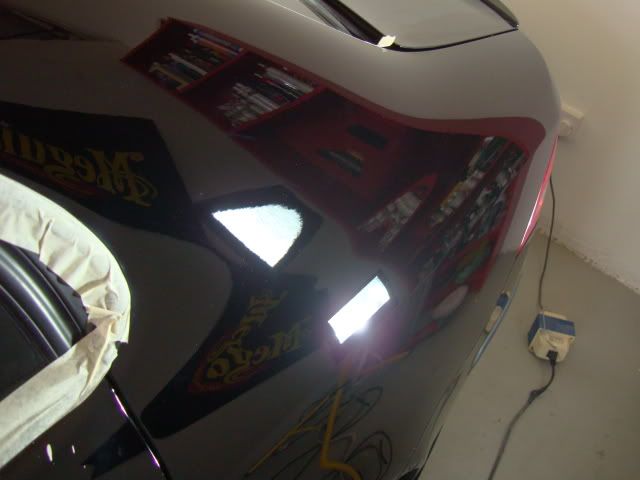

SOME 50/50 pictures

The process was

Mother's clay bar

M105 on 5,5'' LC Green heavy polishing pad with UDM

Menzerna 85RD on 5,5'' LC Black fishing pad with UDM

Sonus paintwork clearness on 5,5'' LC Blue pad with UDM

Nanolex basic paint sealant

Some before pictures

SOME 50/50 pictures