Kevin,

So we talked about paint leveling on the bodyshop side of things, what if we look at paint leveling on the detailing side of things. Generally speaking Im not talking about a level surface as in orange peel removal, but as in complete scratch and defect removal. The old theory of compounding with a wool pad and then refining to remove the wool the coming back to remove holograms has obviously been changed with product development and game changing abrasives whether they would be liquid or foam. Now let me talk about my experiance with the Abralon system that you highly speak of. One thing I should say is that, I should have purchased it sooner and listened to you.

So were are working on a car where the general defects ( swirls, rids, waterspot etching, and so on. ) The defects are deep and will take some time to level. Is it safer to sand them or polish them.

From experiance, I find that certain abrasives will safelty remove less clear then the old school traditional methods. Persay what if the abrasive is Mirka abralon in 4000 grit on soft paint. The 4000 grit may remove defects cooler and safer then opposed to a so called "buffing the paint" Now on the flip side of things on harder paint. 4000 grit abralon may not remove the swirls and a heavier abrasive may be needed such as 2000 grit or even something like your personal favorite Kevin, Surbuff and M101 or should I say m105. :biggrin: In theory paint is being leveled no matter which way you like to do it. What if we could changed the rules of thinking even further and almost entirely remove any polishing, or knock it down to only one step of polishing. Which can be done! Im sure you know this. :bow Whats stopping us as detailers to look into finer papers likes 6000, 8000, 12000 grit? Virtually allowing us to use a super fine polish to remove the sanding defects. Obvious a factor that would come into play would be interface, pad pressure, rotation speed, and such. What would you find safer and and a whole lot more fun to do?

Lets take a paper like 12000 girt, and add water to the mix. Thinks its possible to hydroplane a film disc across the paint to create a almost final shine? Just something running threw my head as thoughts and playing around happens. could we see the day of polish liquids be virtually gone? Keep in mind a few years ago if you said you could correct paint without a rotory I would have laughed at you! Now today I find my rotory collecting dust more and more.

So when does the madness stop. Is it these crazy thoughts that become a reality into game changing products? I guess only time will tell.

Barry, your mind runs as fast as your fingers type.

Let me break this down in sections, and give my opinion that way.

Kevin,

So we talked about paint leveling on the bodyshop side of things, what if we look at paint leveling on the detailing side of things. Generally speaking Im not talking about a level surface as in orange peel removal, but as in complete scratch and defect removal.

I hope we can agree to reserve the term

leveling for those instances when we want to minimize the peak and valley variances of a paint surface. This way, discussions about leveling or truing of the surface won't get overly confusing for newbies.

At least for the remainder of this discussion:

To

level a surface means to minimize the peak and valley variances of the surface.

Orange peel, waviness, and long, level sanding marks shall be categorized here.

To

refine a surface means to minimize or eliminate unwanted elements from the surface other than those listed above.

Elements include scratches, pinhole-sized divets, or etching marks (isolated low spots).

These definitions are as distinct as I can think to make them right now.

I wish to make the distinction because we could feasibly refine or eliminate the imperfections from an orange peeled surface without eliminating its curvy peaks and valleys landscape.

In other words, if you said to me:

Barry: Kevin, see that sandy desert out yonder?

Kevin: Yes Barry.

Barry: If I asked you to level it with this flat shovel, how would you do it?

Kevin: I would take shovels full of sand from the flowing hills, and place them into the valleys until the surface was flat.

Barry: And if I asked you to refine the desert landscape, what would you do?

Kevin: Well Barry, I would take my flat shovel and pat the sand flat until it all of the sand grains were tightly packed together.

Barry: You're hired! :dig

The old theory of compounding with a wool pad and then refining to remove the wool the coming back to remove holograms has obviously been changed with product development and game changing abrasives....

... Whats stopping us as detailers to look into finer papers likes 6000, 8000, 12000 grit, effectively allowing us to use a super fine polish to remove the sanding defects...

Nothing, except technology, and a company that sees the potential for financial gain in making a product for this specific purpose.

Suppose

you made sheets and discs for us?

Better yet, what if you only made sanding squares, 1"x1"? :mmph:

Call 'em Barry Squareys or something like that.

Hey, squares make it easier for me to explain this stuff. :typing:

What might occur as we use the squares?

What would be the factors that limit sanding performance?

I'm thinking this through as I type, so take it all with a grain of salt. :hairpull

No scientific data or research going on at my desk.

ray1:

These two factors pop into my head:

Pressure points and void areas.

Pressure points.

Instead of grading Barry Squareys by

grit size, you use a rating system that identifies your sheets by

how many grains each one uses.

These are

perfect grains by the way- all exactly the same and shape.

Pyramid shaped I suppose, with the base of the pyramid attached to the square.

Taking into account the machine's weight and user applied pressure, your engineers determine that each sanding square can withstand 1 pound of downward pressure before the sheet crumbles.

In real-world sanding, too much pressure causes sanding particles to dislodge.

We don't have a problem with sandpaper crumbling, thank goodness for that!

Therefore:

The 4-grain square would have .250 pounds of pressure atop each grain.

The 8-grain square would have .125 pounds of pressure atop each grain.

The 16-grain square would have .0625 pounds of pressure atop each grain.

The 32-grain square would have .03125 pounds of pressure atop each grain.

The 64-grain square would have .015625 pounds of pressure atop each grain.

The 128-grain square would have .0078125 pounds of pressure atop each grain.

This goes on and on to whatever degree you want it to.

But, there comes a point when there's very little pressure placed upon each grain, so cutting power is virtually nil. In fact, each grain barely cuts into the paint.

Suppose you place the maximum amount of grains you can possibly fit onto your sheet, and the number is virtually uncountable. In fact, the surface is so tightly packed with abrasive pyramids, it

feels as smooth as a piece of glass. You magnify the face of the sheet under a microscope, you realize that the sanding face of the sheet even

looks as smooth as a piece of glass!

Void areas.

With so little space available between the grains:

Where is the abraded paint going to go?

If you happen to wet sand, where is the water going to go?

This could be a problem, eh?

If the residue immediately suffocates cutting power by coating the abrasive pyramids, your sanding squares would offer very short lived cutting power.

If the water had no channels to enter, the sanding square would simply hydroplane until the water was eventually pushed aside.

Would there be a suction problem, causing the square to stick to the surface like a suction cup?

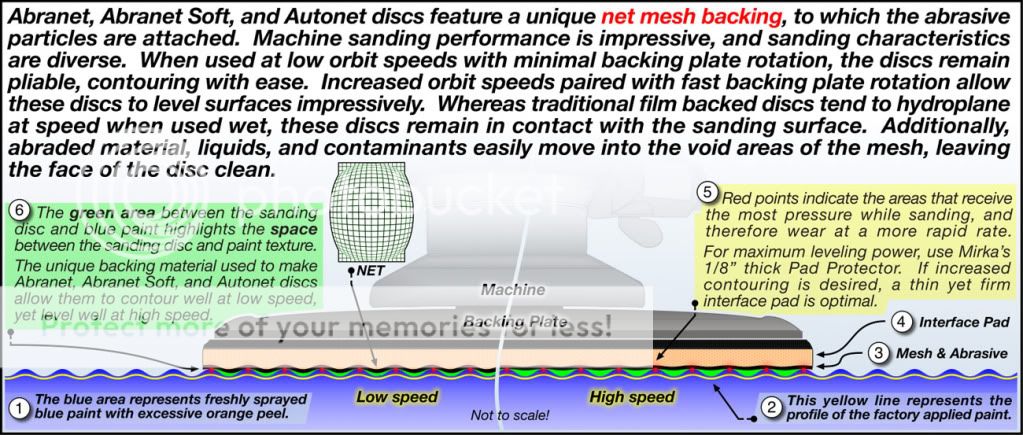

Interesting. Perhaps not a great analogy, but I hope that it makes a little bit of sense. At some point, it seems to me that we'd have to use a mesh backing, or a pin-holed film backing, or some sort of material that would allow water and abraded paint residue to evacuate the area between the disc and the paint.

Vacuuming? A slurry and pump system? Perhaps.

In the case of sanding discs, maybe the abrasives could be lined up like straight spokes on a wheel?

Perhaps curved in a spiral fashion? Or just in straight and parallel lines? Hundreds or thousands of them?

I think someday we'll see discs and buffing pads that work in a manner similar to stone polishing flexible diamond discs. Hard yet flexible pads impregnated with diamond grains, or some sort of abrasive. Envision the way paint cleansing clay works.

We'd use them along with a mist-on lube, or water.

Is it possible to hydroplane a film disc across the paint to create an almost final shine? Just something running threw my head as thoughts and playing around happens. could we see the day of polish liquids be virtually gone?

You're wondering if we could somehow fill the low points of the paint with water or some other filler, so that only the high points remain, and the disc will only affect those points?

I think we discussed something similar to this a while back.

In that discussion, I mentioned this:

"In reference to water or lubricating agents in general:

Since liquids are not easily compressed (most times they are deemed to be not compressible for simplicity sake), the layer of liquid might cause the pad to "float" or ride atop the liquid to some degree. If the pad also features a layer of liquid spread across it, the net effect might be one that sees only minimal contact between the pad and paint surface. Consequently, only the highest of points of the paint surface are being affected, and the newly formed paint surface would lack sharp or inconsistently shaped features.

To envision this, imagine that you are going to skip a rock across a pond of water, and the water is at rest (so its surface is basically flat). The pool of water has small pieces of grass sticking through the top, and you want to cut a path through the grass so that it is flush with the water level. You sharpen the edge of the rock so it will cut through, and you make sure when you throw the rock, it has a lot of rotational speed.

This scenario is very similar to what is likely occurring during your "burnishing" step when you polish paint with a finishing polish. In this case, the pond water represents the liquid covering the paint, the grass blades represent the high points of paint that your pad is going to "cut through", and the rock represents your buffing pad. Not a perfect analogy, but I hope you get the gist of the comparison."