dsms

New member

- Dec 16, 2007

- 190

- 0

I got my cyclo a few days ago and went right to work testing it. I figured the cyclo would be a simple "One Step" and finishing polish machine only and that any real correction work would need to be done using my rotary, but I was wrong. I took out my trusty test panel today and wanted to see just how much correction power the Cyclo and Gloss It polishes had.

First let me say I really like this machine. Its smooth, balanced and leaves a hologram free finish even after heavy correction...plus one handed polishing is a breeze. As an owner of a Flex 3401 and Makita I will say the cyclo impressed me. The whole time I was comparing it to the both machines and it definatley held its own. Yes of course the raw power of the rotary is far more than the cyclo but with the cyclo I dont have to worry about nasty holograms, even on the softest of paint. Plus the new twin edge adapters are great, changing the double sided pads is so nice. I can go from cutting pads to fiishing pads in 20seconds.

Now onto the test...

I swirled up one section of the panel with a stiff bristle carpet brush using heavy pressure.

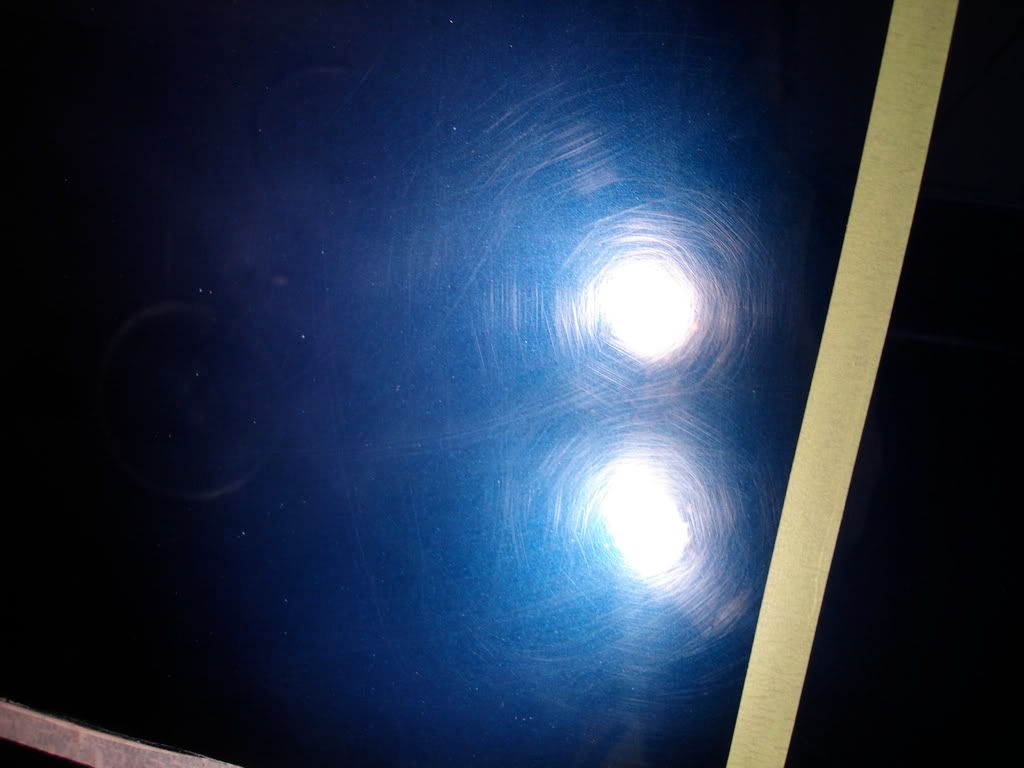

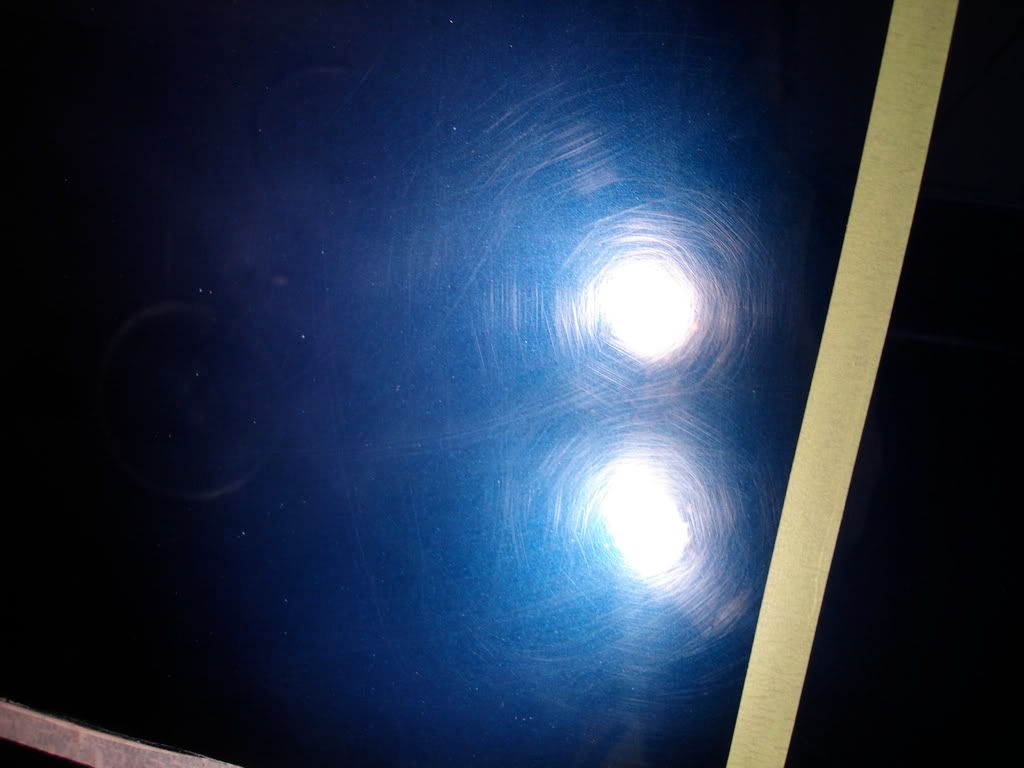

This is what I was left with

The swirls were pretty heavy and as you can see there are many RDS left in the finish.

I knew it would take an agressive combo to correct this so out with the orange pads and Gloss it Extreme cut

The pads were brand new so I used a little extra polish to prime them

And now I dry spread Extreme cut evenly acorss the panel to reduce splatter when I turned the machine on

After spreading the polish and a few passes

The end result after ONLY 1 hit of Gloss It Extreme cut and the cyclo

A very good amount of defect was removed, still some RDS were left but it was to be expected, so far I was super impressed.

I made sure to apply a good amount of pressure when working extreme cut so I could polish out the deeper defects and as it began to breakdown further I lightened up the pressure and refined the finish. I would say after only 1 hot of EC and the cyclo using orange pads I achieved 70% correction, around 85% in some of the areas without as many RDS.

Now onto removing the finer scratches I went to Gloss It Evolution cut and the yellow pads. I would have gone to green pads because this techinically would be the finishing stage of polishing but I needed some more bite from the pad if I was going to remove even more defects so I used a yellow pad instead.

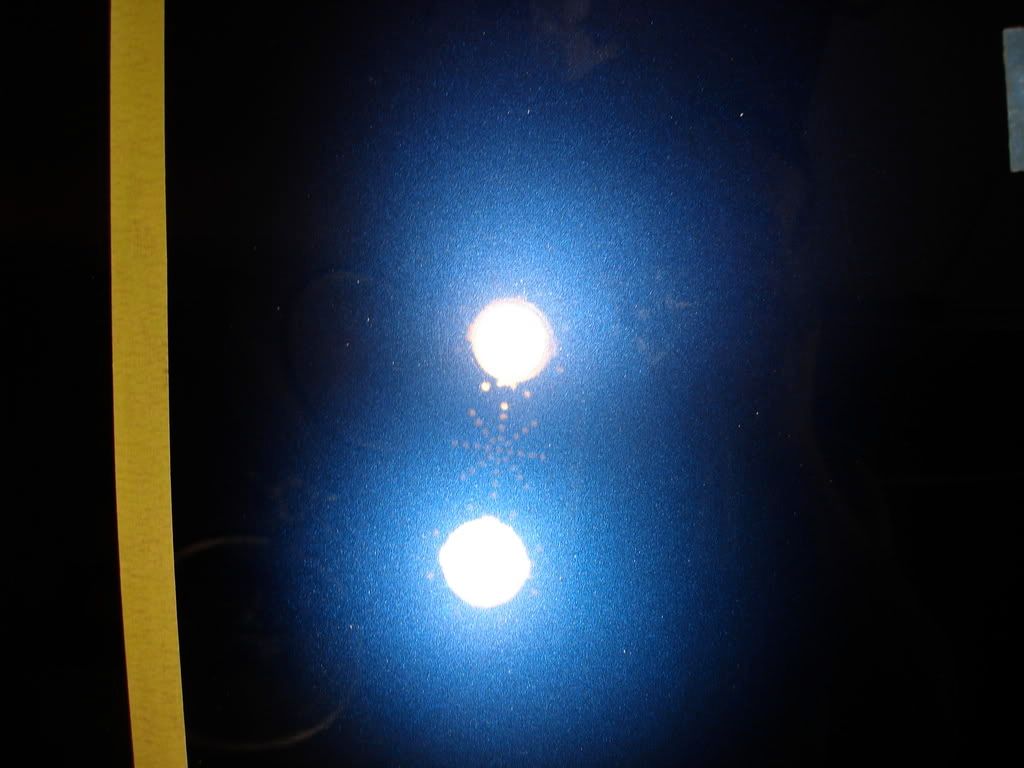

After using Evolution cut

After an IPA wipedown I made sure there was no filling and carefully inspected the finish. I would say it was 90% perfect, the only exeptions being a few deep deep RDS which I wasnt able to polish out.

This was a bit of an "extreme situation" being as the swirls I induced were from stiff brushes and not regular washing towels etc. If I was going for 100% correction on this bad of a finish and used my rotary I would have choosen a wool cutting pad - either gloss it white lambswool or edge yellow with extreme cut BUT the only problem would be the left over nasty holograms. With the Cyclo I dont have to worry about that and still I was able to achieve a 90% perfect finish in only 2 steps.

So from this

To this

....In 2 steps using a Cyclo

First let me say I really like this machine. Its smooth, balanced and leaves a hologram free finish even after heavy correction...plus one handed polishing is a breeze. As an owner of a Flex 3401 and Makita I will say the cyclo impressed me. The whole time I was comparing it to the both machines and it definatley held its own. Yes of course the raw power of the rotary is far more than the cyclo but with the cyclo I dont have to worry about nasty holograms, even on the softest of paint. Plus the new twin edge adapters are great, changing the double sided pads is so nice. I can go from cutting pads to fiishing pads in 20seconds.

Now onto the test...

I swirled up one section of the panel with a stiff bristle carpet brush using heavy pressure.

This is what I was left with

The swirls were pretty heavy and as you can see there are many RDS left in the finish.

I knew it would take an agressive combo to correct this so out with the orange pads and Gloss it Extreme cut

The pads were brand new so I used a little extra polish to prime them

And now I dry spread Extreme cut evenly acorss the panel to reduce splatter when I turned the machine on

After spreading the polish and a few passes

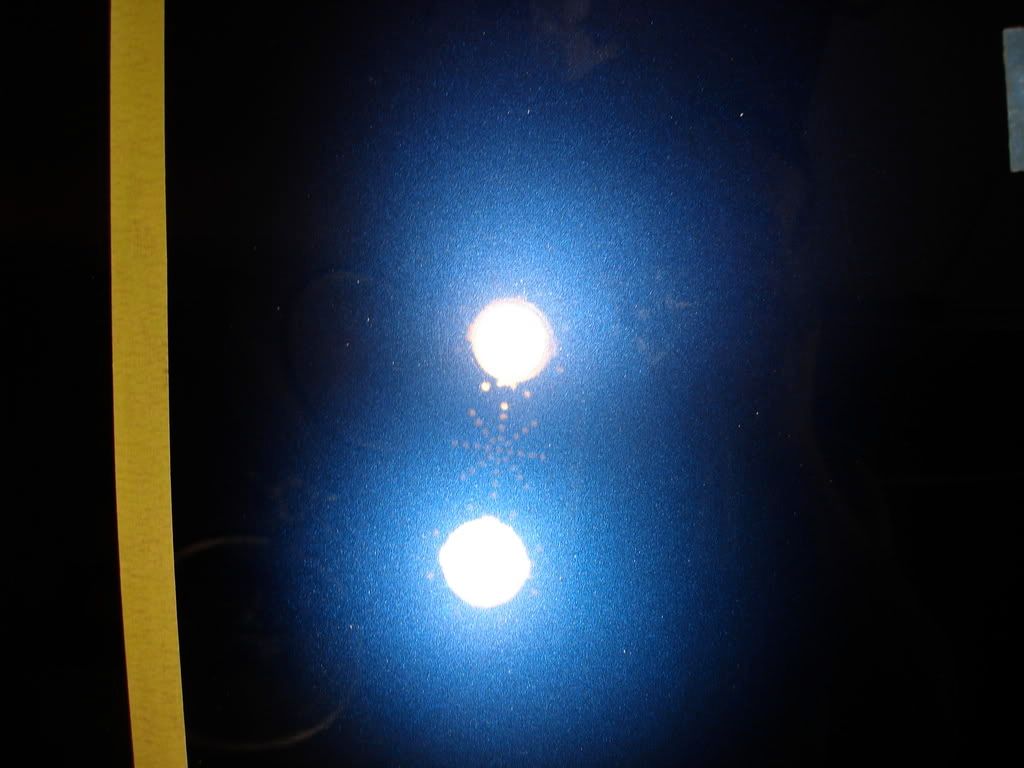

The end result after ONLY 1 hit of Gloss It Extreme cut and the cyclo

A very good amount of defect was removed, still some RDS were left but it was to be expected, so far I was super impressed.

I made sure to apply a good amount of pressure when working extreme cut so I could polish out the deeper defects and as it began to breakdown further I lightened up the pressure and refined the finish. I would say after only 1 hot of EC and the cyclo using orange pads I achieved 70% correction, around 85% in some of the areas without as many RDS.

Now onto removing the finer scratches I went to Gloss It Evolution cut and the yellow pads. I would have gone to green pads because this techinically would be the finishing stage of polishing but I needed some more bite from the pad if I was going to remove even more defects so I used a yellow pad instead.

After using Evolution cut

After an IPA wipedown I made sure there was no filling and carefully inspected the finish. I would say it was 90% perfect, the only exeptions being a few deep deep RDS which I wasnt able to polish out.

This was a bit of an "extreme situation" being as the swirls I induced were from stiff brushes and not regular washing towels etc. If I was going for 100% correction on this bad of a finish and used my rotary I would have choosen a wool cutting pad - either gloss it white lambswool or edge yellow with extreme cut BUT the only problem would be the left over nasty holograms. With the Cyclo I dont have to worry about that and still I was able to achieve a 90% perfect finish in only 2 steps.

So from this

To this

....In 2 steps using a Cyclo