7PaintGuns

New member

- Oct 6, 2015

- 359

- 0

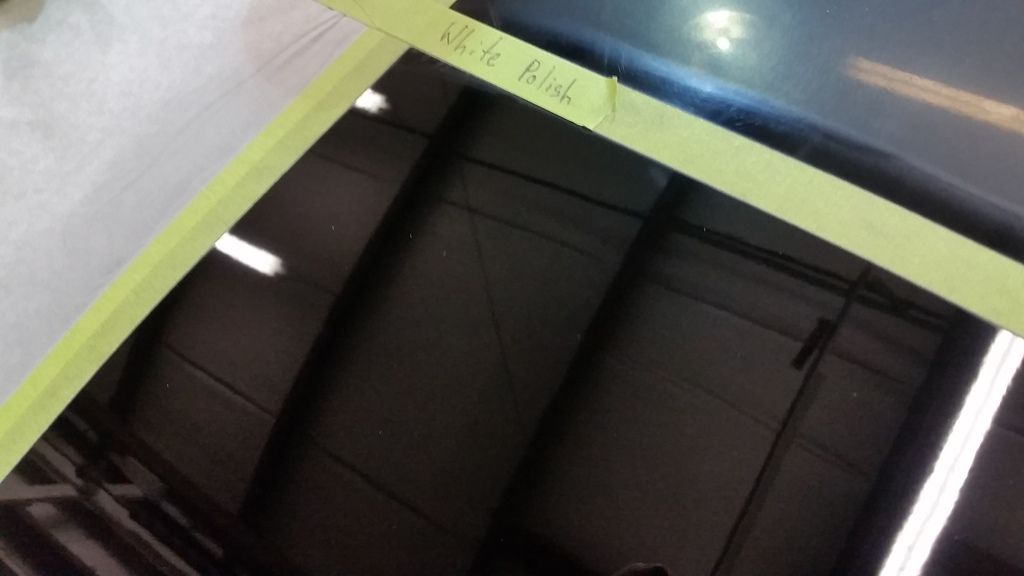

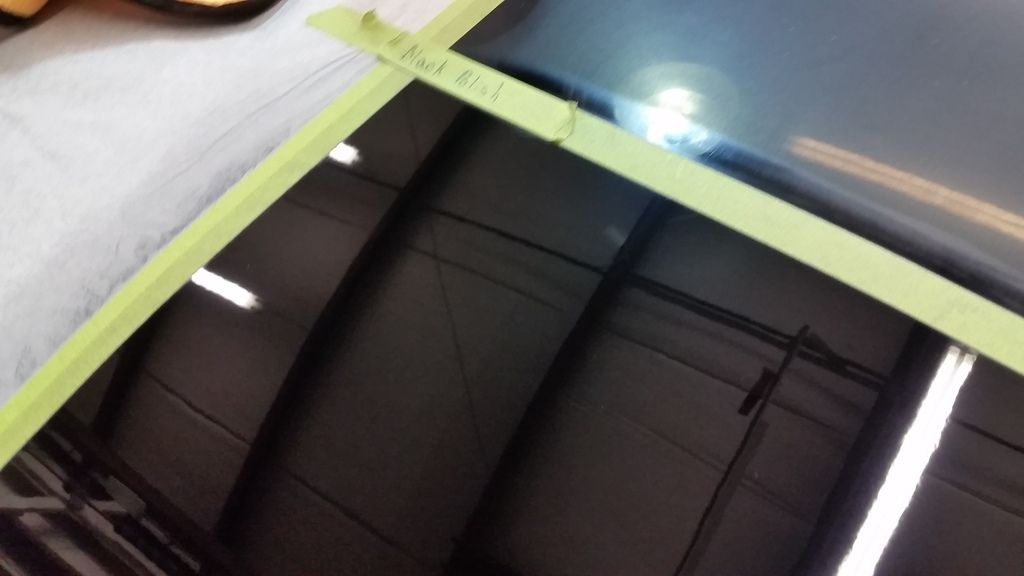

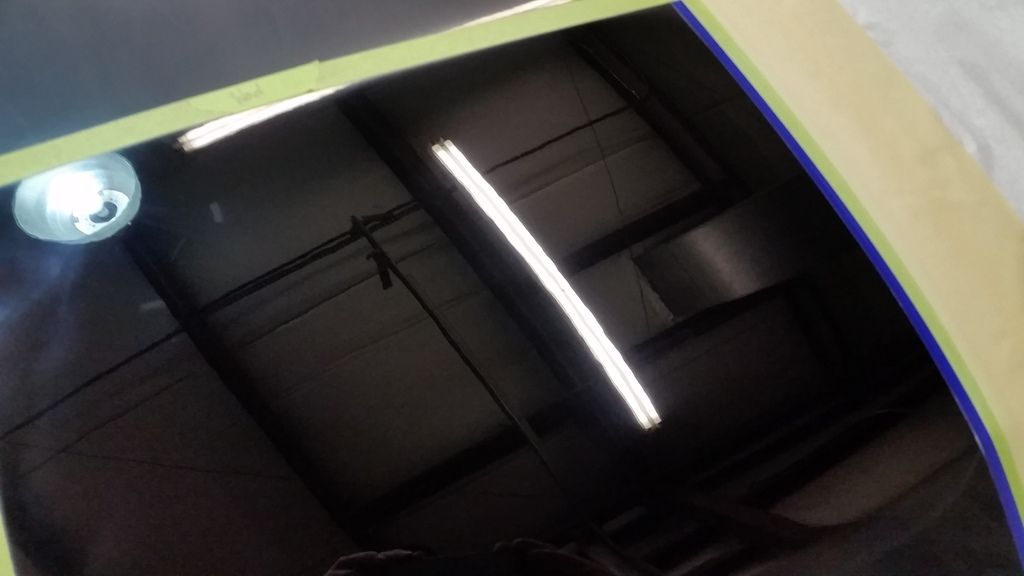

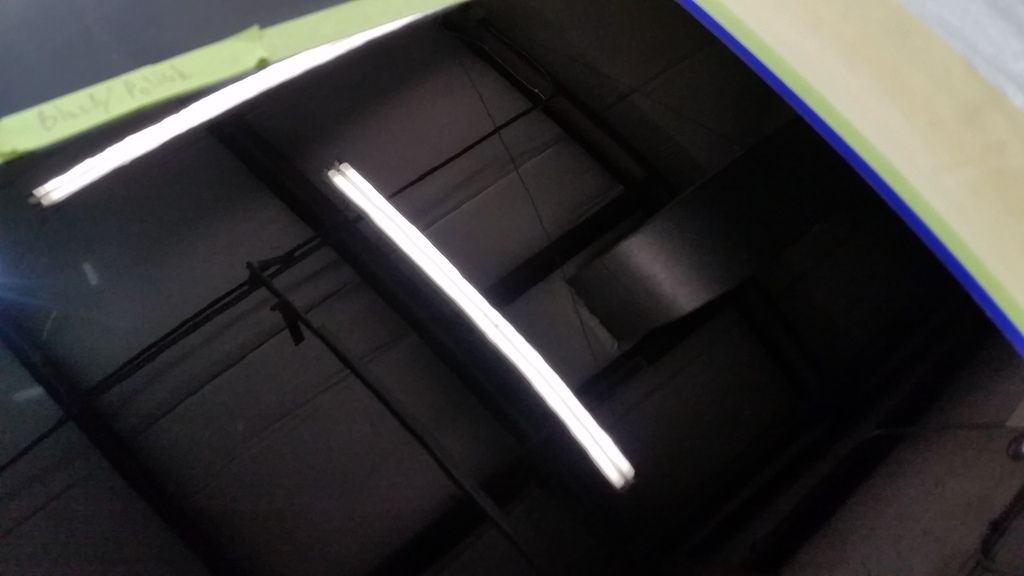

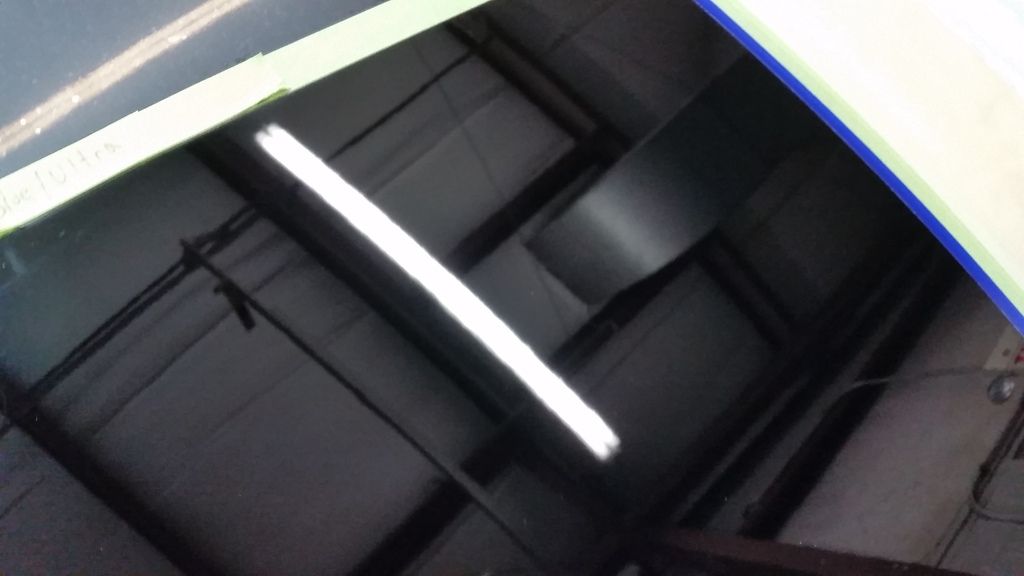

As I had mentioned in this thread http://www.autogeekonline.net/forum/flex-polishers/97011-flex-xc-3401-first-options.html I decided to purchase a Flex 3401 to test at work for assisting with clear coat finishing, mostly on black and really dark colors for hologram elimination. Having used a rotary buffer for many years I would say my skills are just as proficient as the next professionals. Working with recently painted panels (buffed next day) can be difficult as the paint has not fully cured and scratches very easily.

Usually holograms are not something a customer will notice or mention because most cars aren't black and the vast majority of vehicles we paint finish fantastically, but there are exceptions.

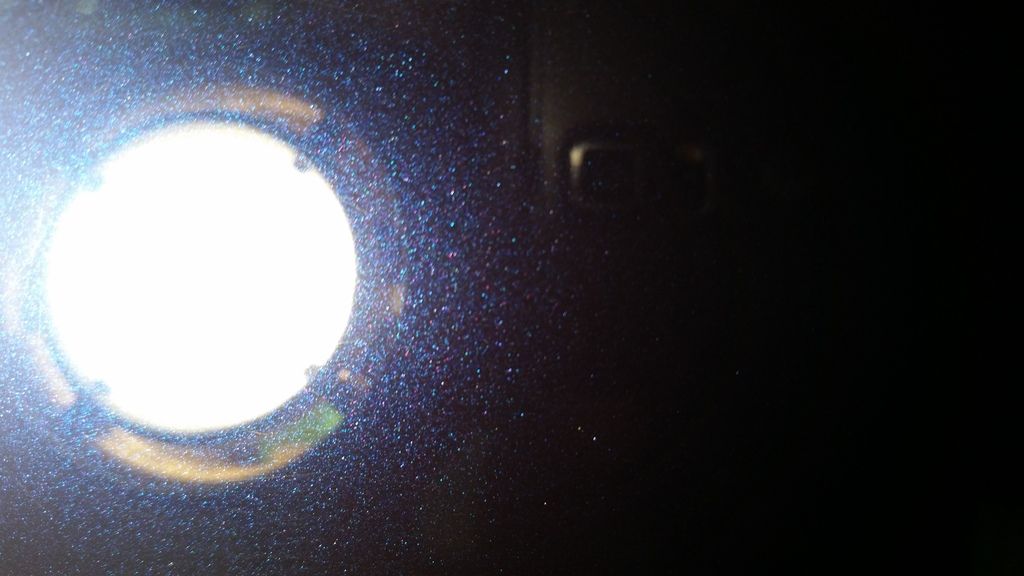

Example 1: Seasons and Time of Day

Most forum members will obviously know that a recently polished or corrected vehicle will look way better in the shade vs the sun. In the winter time, when its cold and grey here in the mid-west, holograms aren't a problem because they cant be seen. In the spring and summer months, the sun is high and holograms become much more noticeable. Autumn represents a different story. Don't ask me why, but having painted for 12 years, swirls and holograms are extremely obvious in the fall, especially in the evening. It may be because the sun is lower in the sky, it might be because there is less humidity in the air distorting the light. I'm not sure, but its obvious if you pay attention year to year.

Example 2: Higher end Vehicles

More than 3/4 of the vehicle delivered from our shop are higher end vehicles. Not Lamborghini and Ferrari, but normal DD vehicles involved in accidents such as Lexus, Mercedes, Ford (Mustang GT, Shelby ROUSH) Acura, BMW, you name it. Obviously these customers can be very picky and they should be. They pay their insurance and want their care repaired properly. Saying that, all delivered cars are finished to the best quality physically possible.

I have written all this because I want to spend 2016 periodically updating this thread regarding rotary and dual action buffers/polishers and their finishing qualities at my experience level. This will include Winter/Spring/Summer/Fall for a full spectrum of situations and conditions. I will be doing this at my leisure throughout the year but updating when I can. I'm mainly doing this to log my own experiences and for my own knowledge, but thought some members would like to see what I come up with. This wont be a perfectly written thread and there will be a lot of variable so you will have to take this for what it is. :buffing:

Usually holograms are not something a customer will notice or mention because most cars aren't black and the vast majority of vehicles we paint finish fantastically, but there are exceptions.

Example 1: Seasons and Time of Day

Most forum members will obviously know that a recently polished or corrected vehicle will look way better in the shade vs the sun. In the winter time, when its cold and grey here in the mid-west, holograms aren't a problem because they cant be seen. In the spring and summer months, the sun is high and holograms become much more noticeable. Autumn represents a different story. Don't ask me why, but having painted for 12 years, swirls and holograms are extremely obvious in the fall, especially in the evening. It may be because the sun is lower in the sky, it might be because there is less humidity in the air distorting the light. I'm not sure, but its obvious if you pay attention year to year.

Example 2: Higher end Vehicles

More than 3/4 of the vehicle delivered from our shop are higher end vehicles. Not Lamborghini and Ferrari, but normal DD vehicles involved in accidents such as Lexus, Mercedes, Ford (Mustang GT, Shelby ROUSH) Acura, BMW, you name it. Obviously these customers can be very picky and they should be. They pay their insurance and want their care repaired properly. Saying that, all delivered cars are finished to the best quality physically possible.

I have written all this because I want to spend 2016 periodically updating this thread regarding rotary and dual action buffers/polishers and their finishing qualities at my experience level. This will include Winter/Spring/Summer/Fall for a full spectrum of situations and conditions. I will be doing this at my leisure throughout the year but updating when I can. I'm mainly doing this to log my own experiences and for my own knowledge, but thought some members would like to see what I come up with. This wont be a perfectly written thread and there will be a lot of variable so you will have to take this for what it is. :buffing: