spiralout462

New member

- Dec 14, 2012

- 1,771

- 0

I would hate to stick that magnet on the hood of my truck! I wonder what the retail price of that thing is?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

<--- pulls up a chair, pops open a Pliney and waits for VIP special on new Rupes 12

Hey Mike,

I know in the past you said the Rupes wasn't your go to polisher due to the bogging down, how is the Rupes 12 when faced with similar situations? Just wondering because I like my Rupes 15 but I'm always looking for the latest tools. Thank you.

Could you post a link to where you believe Mike said this? I'd like to read the context of it.

All free-rotating DAs will slow or stop rotating with friction/pressure so that would be like saying all DAs except the Flex are inadequate as a go-to polisher, and I have a feeling there's more to the context of what he was saying than the way you've summarized it. Seeing the full discussion would help frame it.

Thanks.

Hey Mike,

I know in the past you said the Rupes wasn't your go to polisher due to the bogging down, how is the Rupes 12 when faced with similar situations? Just wondering because I like my Rupes 15 but I'm always looking for the latest tools.

Thank you.

Could you post a link to where you believe Mike said this? I'd like to read the context of it.

All free-rotating DAs will slow or stop rotating with friction/pressure so that would be like saying all DAs except the Flex are inadequate as a go-to polisher, and I have a feeling there's more to the context of what he was saying than the way you've summarized it. Seeing the full discussion would help frame it.

Thanks.

The technique I left it on the youtube channel. Lol

When I attempted this. Michael Stoops got out Meguiars MF polishing pad and M100.

I asked him why not use the MF cutting pad instead of the polishing pad?

He just looked at me, smiled and just said "just try it" so I did

And yep they were removed, i'd say just as easy or even easier then the Dewalt I was using that night. It did leave a haze however. But I used zero pressure.

I asked him about the Rupes bogging down. So he turned it on, put a ton of pressure and it kept spinning. So I am still not sure what everyone is talking about? :dunno:

But just polished the haze out with M205

I'm not sure if we were even supposed to be "technically" wet sanding and buffing lol. Since it was Thursday night.

A few AG members were there. I also want to take the advanced class. My Body shop skills came out pretty easily that night. My wet sanding, I had spattered compound everywhere haha :laughing:

Yet the Meguiar's guys were working just like me or maybe even more than me, and they were spotless clean, I looked like I had came out working at a body shop the whole day haha

It was a blast however

I want to see how the Rupes reacts to curved panels. I've only gotten the chance test it out on flat test panels.

Joe Fernandez from Superior Shine has a little thread on FB. "Ask Superior Shine" So I asked, the Rupes or Flex

Art

The technique I left it on the youtube channel. Lol

When I attempted this. Michael Stoops got out Meguiars MF polishing pad and M100.

I asked him why not use the MF cutting pad instead of the polishing pad?

He just looked at me, smiled and just said "just try it" so I did

And yep they were removed, i'd say just as easy or even easier then the Dewalt I was using that night. It did leave a haze however. But I used zero pressure.

hernandez.art said:I asked him about the Rupes bogging down. So he turned it on, put a ton of pressure and it kept spinning. So I am still not sure what everyone is talking about? :dunno:

It was a blast however

I want to see how the Rupes reacts to curved panels. I've only gotten the chance test it out on flat test panels.

Joe Fernandez from Superior Shine has a little thread on FB. "Ask Superior Shine" So I asked, the Rupes or Flex

Art

Saw this discussion over the weekend and I'm happy to have chimed in to straighten out any confusion.

The pads work great. The tools works great too. Here's what I posted to a thread on Facebook that Paul Dalton started and that's,

I'm not impressed easily my new tools, pads or products but these two new tools impress me.

The 1932 Ford Phaeton we had here I buffed out using these new tools and I really fell in love with them. Next I re-polished out my 1987 Silverado because it's BIG and that gave me hours of buffing time to really punish these new tools and again I was impressed.

I also de-swirled the 1986 Porsche using these new tools and I was impressed.

You guys are going to love these two new tools. I never jumped on the hype train for the 15 and 21 after they reached the tipping point and their names and popularity went cyber-mainstream, but I'm impressed with these two new tools so much that I'll volunteer to be the Conductor of this train.

We'll be showing these new tools the Thursday after SEMA and the following Thursday and I have a list of cool cars to buff out using and showcasing these tools.

I'm excited about these new tools.

:dblthumb2:

Mike Phillips said:Secret meeting with the Flex Engineers!

Upon our arrival on Thursday afternoon, we were welcomed to the Flex Corporate Offices and then introduced to most of management and key personal.

After introductions we had what I think was one of the best parts of our trip and that was a chance to meet with and discuss power tools with the Flex Engineers. Sorry but no pictures of the actual meeting as it was private but here's the skinny... both Nick and I had a chance to talk one-on-one with all the top engineers at Flex including Dirk Rock, the engineer behind the Flex PE14

This was our opportunity to share our thoughts about tool design and the direction and needs of both the enthusiast and professional markets. It was truly an honor to sit and discuss tools and technology with the Flex engineers. I brought along two Brinkmann Swirl Finder Lights and gave one to Dirk since his job includes testing the paint polishing tools on painted hood panels in the training room.

Sorry but I can't share what we discussed nor any pictures of Nick and I with the engineers, but here's the meeting room...

Meeting Room

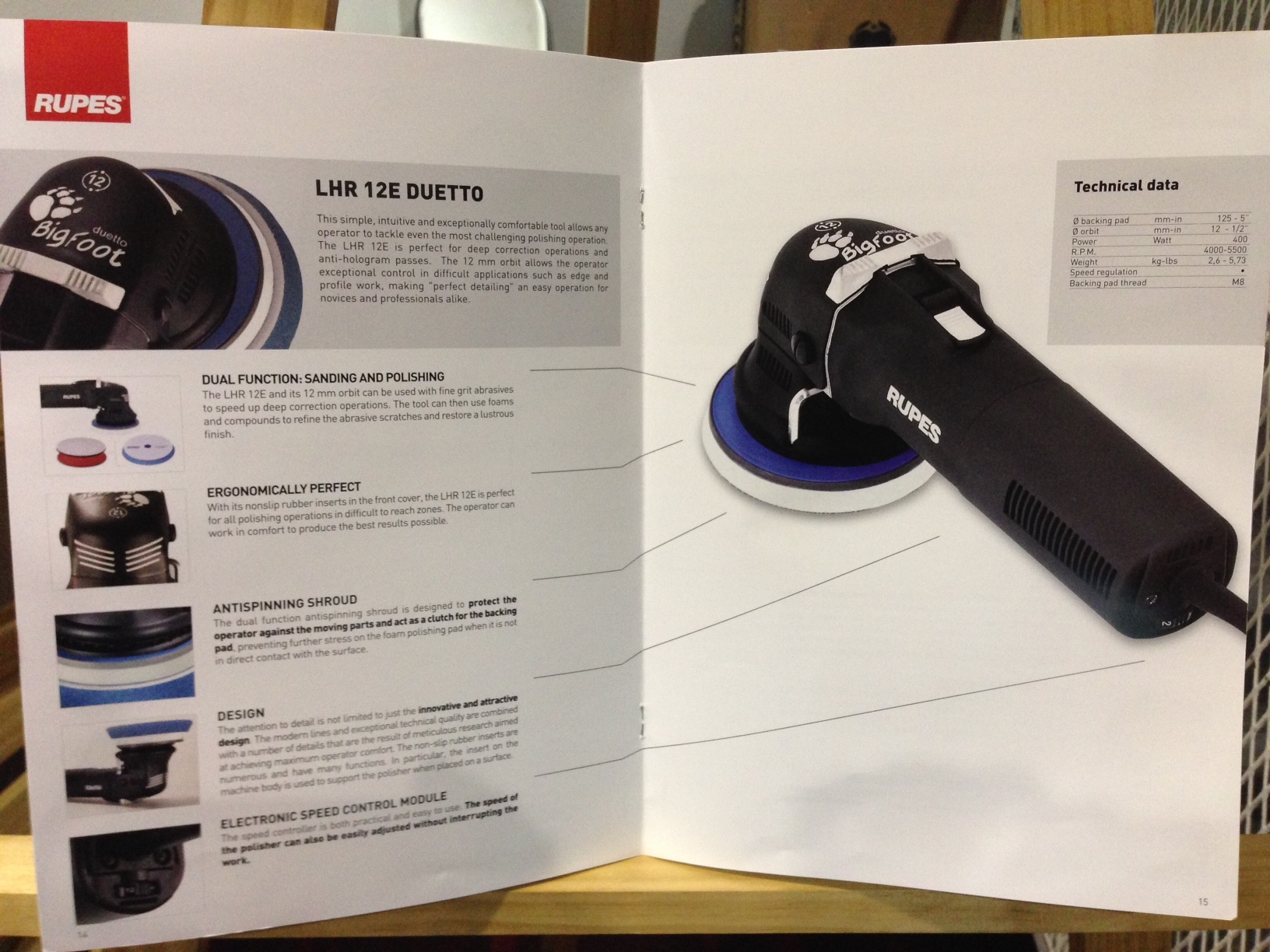

Mike--what is it about the Duetto that impressed you more than the 15 and 21?

The simple answer is I like how it works better. I didn't know why I liked how it works better till I spoke with Marco at SEMA.

He told me because it has a shorter orbit stroke than the Bigfoot 15 and Bigfoot 21 they purposefully desinged it to offer a higher rotation speed or higher rpm to go with the smaller orbiter stroke.

I didn't know this technical feature for this tool when I recieved the prototypes back in April, all I knew after using the tool is that I really liked how it operated.

I can believe that. One thing I notice with the Bigfoot, sometimes the large stroke makes it hard to judge how close you can get to the edge of something with the pad.

The simple answer is I like how it works better. I didn't know why I liked how it works better till I spoke with Marco at SEMA.

He told me because it has a shorter orbit stroke than the Bigfoot 15 and Bigfoot 21 they purposefully desinged it to offer a higher rotation speed or higher rpm to go with the smaller orbiter stroke.

I didn't know this technical feature for this tool when I recieved the prototypes back in April, all I knew after using the tool is that I really liked how it operated.

I've personally never stated either the Rupes 15 or 21 were not my go-to dual action polishers due to them bogging down.

I appreciate RS99's asking for a link to anywhere I used the words bogging down in context with the Rupes polishers as the context will show my use of the words bogging down were in a reply to Art and the words bogging down were his words not mine. I simply repeated them as a reference to his post because he used them in his post.

In this article I wrote about removing sanding marks using the Rupes Bigfoot 21,

Removing #1500 Sanding Marks with Rupes Bigfoot 21 Polisher

The discussion about the Rupes polishers bogging down comes up when Art Hernandez brings it up in a discussion he had with Mike Stoops at Meguiar's.

in Post #11 of my thread on removing wetsanding marks with the Rupes Bigfoot 21 Polishers, here's Art's post followed by my post in context...

Here's my answer "in context" and the pertinent part of my opinion and experience in bold red letters.

Mike's a sharp guy and remember...

"You don't know what you can do until you try"

The bogging down is when buffing out curved panels as you'll have only a small portion of the panel touching a small portion of the face of the pad and this can impede pad rotation.

The Thursday Night Open Garage classes were always fun and it's good to see they continue the tradition.

I make it a best practice to buff out entire cars, not just spots on a flat panel to really get the feel for a tool, pads, product or technique when possible.

The first time I used the Rupes polishers I chose a BIG car with lots of flat panels and LOTS of curved panels. Even made a time lapse video of the project and I think this was the FIRST time lapse video ever made showing a car being buffed out from beginning to end using the Rupes polishers.

Here's the link to the full write-up and a portion below...

Rupes Polisher Time Lapse Video - 1955 Ford Crown Victoria

Here's the time-lapse video Yancy took for me as I buffed this classic out from start to finish...

On the passenger side I used the Rupes 21 and on the driver's side I used the Rupes 15. There was about a 20 minute time savings using the larger pad, larger stroke machine over the smaller pad, smaller stroke machine but my opinion is that for most body panel designs on modern cars the 6" pad will be a better match.

This tool definitely has a lot more correction ability plus power over a traditional DA Polisher like the Porter Cable 7424XP.

I did find that when buffing a curved panel, either concave or convex, the uneven pressure applied to the face of the pad will slow down and even stop pad rotation. The key is to focus on the panel and keep the pad as flat as possible to the surface.

And here's the complete and in-depth write up using the very cool 1955 Ford Crown Victoria...

Rupes side by side detail - 1955 Crown Victoria

Joe is not only incredibly nice he's also very knowledgeable and always conducts himself in a professional manner. His word is as good as gold. I count him as a very good friend.

Saw this discussion over the weekend and I'm happy to have chimed in to straighten out any confusion.

:xyxthumbs:

Dear Sirs,

Please stop posting pics of the Duetto and the Mini until the items are for sale.

Thank you,

An Interested Customer

PS Thank you and have a nice day

I guess my point of the post I made was what machine do you prefer flex 3401 or Rupes?