bwatereagleman

New member

- Sep 17, 2012

- 34

- 0

Test Spot vs Working Area - Using a Flex 3401

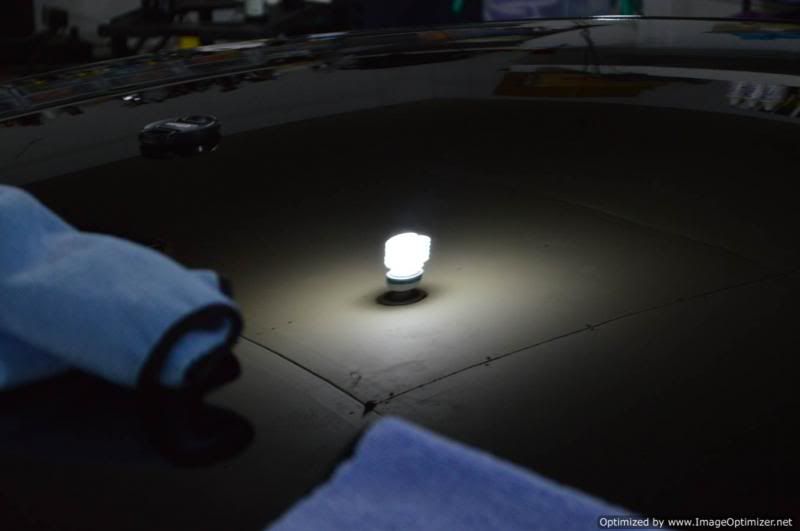

As with all new projects, I use a test spots to see what is going to work best for the project. Once I have nailed down the process, I get to work. Unfortunately though, due to poor lighting in the garage space (which is going to be another post later and no swirl light yet), I will finish out a couple of panels before I check the results again. What I find is sometimes the results of the worked panels aren't as good as the test spot. Usually, I find there are more swirls and defects left behind than the test spot.

So, with everything being equal such as pads, machine, and product, there must be something I am doing differently in my "working" process than the test spot. Correct? After thinking it through, I used the same number of passes as well as kept my arm speed relatively the same. I racked my brain trying to think about what is happening to finally have the light bulb flicker on.

I say flicker on for a reason. Sometime ago, I read a post/thread about "expanding the work area when using the Flex 3401." I don't know if that was the name of the post or not, but I seem to remember a large, older model Chevrolet hood where Mike Phillips buffed/polished an entire hood. Or was it a half? I've searched for the thread/post, but I just cannot seem to find it.

Here is what I think might be happening. The test spot is usually the first step. What I mean is the test spot is performed with a freshly primed pad with three dime-sized dabs of product worked into an approximately 2ft x 2 ft section, however when I get to work, I spread that amount into a larger working area. I suppose my question is, could this be the reason I am getting a different result? If so, when using the Flex, is not a good practice to work on a larger area than the test spot? But if it is ok to work on a larger area, are you still using 3 dime sized drops or do you increase the amount of working product for the larger working area (ie. double the amount of working product for doubling the working area)? As far as the test spot is concerned, is 3 dime sized drops ample or excessive?

Just for additional consideration, I am working at a used auto dealership where the vehicles greatly differ in condition, and as expected, turn around time is important. I primarily use Wolfgang Uber Compound for the vehicles with heavier defects and XMT 360 for polishing/waxing. The vehicles with lesser defects, I may only one-step with the XMT 360. I also have a variety of pads which include yellow, orange, and white Lake Country CCS 6.5 pads.

As with all new projects, I use a test spots to see what is going to work best for the project. Once I have nailed down the process, I get to work. Unfortunately though, due to poor lighting in the garage space (which is going to be another post later and no swirl light yet), I will finish out a couple of panels before I check the results again. What I find is sometimes the results of the worked panels aren't as good as the test spot. Usually, I find there are more swirls and defects left behind than the test spot.

So, with everything being equal such as pads, machine, and product, there must be something I am doing differently in my "working" process than the test spot. Correct? After thinking it through, I used the same number of passes as well as kept my arm speed relatively the same. I racked my brain trying to think about what is happening to finally have the light bulb flicker on.

I say flicker on for a reason. Sometime ago, I read a post/thread about "expanding the work area when using the Flex 3401." I don't know if that was the name of the post or not, but I seem to remember a large, older model Chevrolet hood where Mike Phillips buffed/polished an entire hood. Or was it a half? I've searched for the thread/post, but I just cannot seem to find it.

Here is what I think might be happening. The test spot is usually the first step. What I mean is the test spot is performed with a freshly primed pad with three dime-sized dabs of product worked into an approximately 2ft x 2 ft section, however when I get to work, I spread that amount into a larger working area. I suppose my question is, could this be the reason I am getting a different result? If so, when using the Flex, is not a good practice to work on a larger area than the test spot? But if it is ok to work on a larger area, are you still using 3 dime sized drops or do you increase the amount of working product for the larger working area (ie. double the amount of working product for doubling the working area)? As far as the test spot is concerned, is 3 dime sized drops ample or excessive?

Just for additional consideration, I am working at a used auto dealership where the vehicles greatly differ in condition, and as expected, turn around time is important. I primarily use Wolfgang Uber Compound for the vehicles with heavier defects and XMT 360 for polishing/waxing. The vehicles with lesser defects, I may only one-step with the XMT 360. I also have a variety of pads which include yellow, orange, and white Lake Country CCS 6.5 pads.