am I correct or am I still going to need/want a rotary for gelcoat correction?

Depends on how deep the oxidation is and your expectations for a "nice" finish.

I cover deep oxidation in my boat classes, the next class is February 10th and 11th, 2018 - The fastest and easiest way to remove deep oxidation is to machine sand and then compound with a wool pad on a rotary buffer.

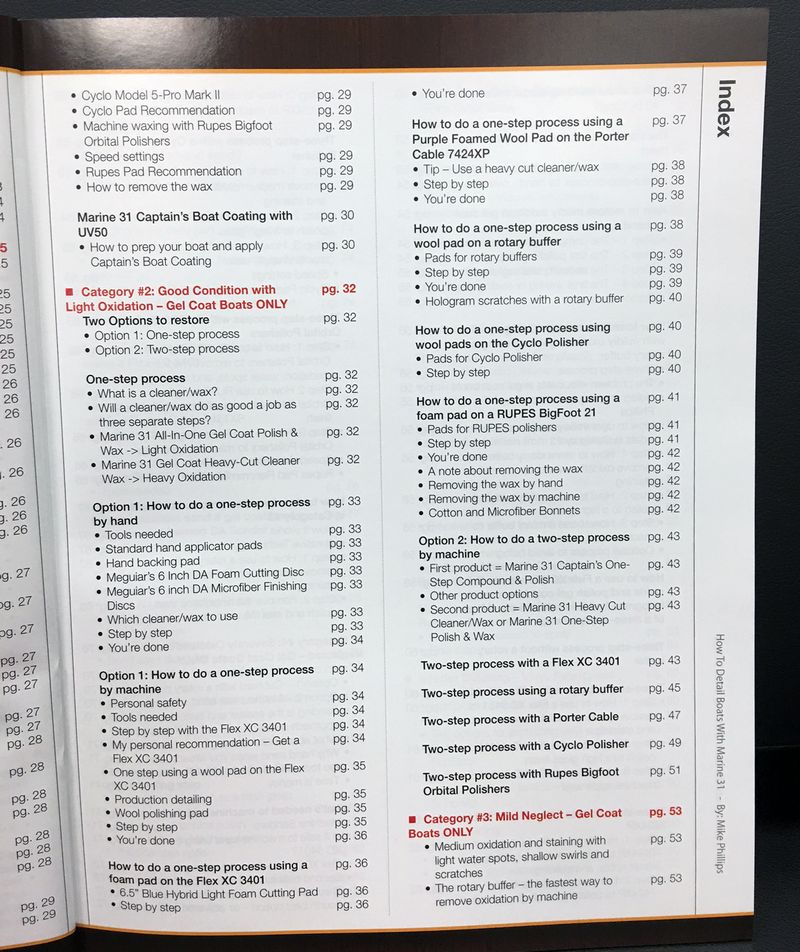

I also cover this in my boat detailing how-to book. This is the most in-depth how-to book I've ever written due to how many tools there are on the market and also the wide spectrum of "conditions" boats can be in. Suffice to say, it's a lot more complex to "type" about than car detailing.

There a 6 pages to the index alone. Here's the third page,

I divided boat conditions into 4 categories,

Category #1 New or Like New

Category #2 Good Condition with Light Oxidation

Category #3 Mild Neglect

Category #4 Severely Oxidized and Neglected

Category #1 you're good to go with a free spinning orbital polisher. Any free spinning orbital polisher s long as you can maintain pad rotation and pad oscillation.

Category #2 you're good to go with any gear-driven orbital polisher or rotary buffer. Oxidation can be removed to a satisfactory level with a free spinning tool but it's going to take longer as compared to any gear-driven tool. Your time, you're money.

Category #3 - At this level of oxidation, the fastest way to and here's the key word, thoroughly remove deep oxidation is with a rotary buffer, wool pad and top notch compound. You can use a gear-driven orbital but it's going to take longer to get the same results you can achieve using a rotary with a wool pad.

Category #4 - At this level of deep oxidation the fastest and most effective way to thoroughly remove oxidation is to machine sand to a fresh base of gel-coat and then remove your sanding marks using a rotary buffer. You can skip sanding and only use a rotary buffer but >you< are going to PUSH hard for HOURS against a surface that

declines or angels away from you, very tough to do for hours. The results will look splotchy unless you REALLY focus on working small areas and closely monitor your pad overlap not only for the section you're buffing but when moving to a new section.

At our boat detailing classes I bring in the WORST condition dark colored gel-coat boats and then show All of the above.

Heck, you can oxidation by hand if you want and I show how in my boat detailing book but what I also say in the chapter on removing oxidation on boats in category #3 on page 54 is this,

Mike Phillips said:

My guess is that anyone attempting to correct the finish on a boat in Category #3 by hand will get about an hour into the correction process before deciding to switch to a machine.

I didn't address how to remove deep oxidation by hand for boats in category #4 because I don't know if there's a human alive that could do an entire boat. BUT if someone wanted to the 4-step process I outline for boats in category # would also work for boats in category #4.