Todapwr

New member

- Apr 27, 2009

- 5

- 0

Hello fellow Autogeek members! This is my first time posting and its not a good one! To make a long story short I was detailing a 2012 GT500 over the weekend, using my PC 7424 which I have had for over 3yrs and only used maybe 20 times since I brought it from Autogeek. While using it on the roof of the car with a LC yellow pad @ the 6 setting the backing plate came off along with the spindle. Leaving a 3" scratch all the way down to the metal! I called Porter Cable this morning to see if this was a problem they encounter before and I was told "NO" and they couldn't find any recalls on such issues. Has any one on here had this same problem? Thanks ahead and be CAREFUL with you PC! Now for the pictures

Old PC 7424

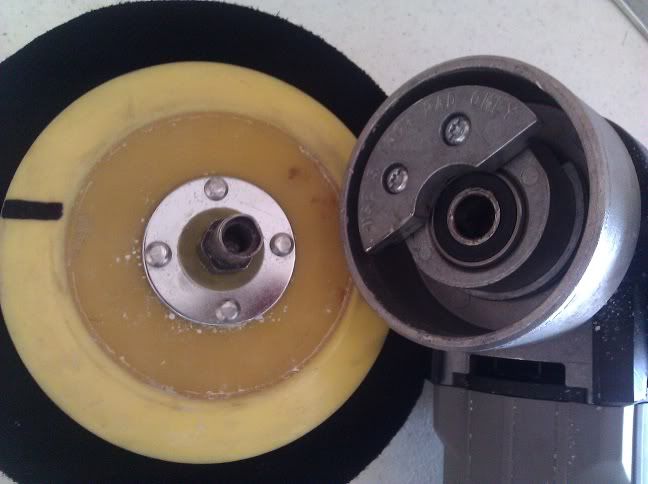

What it should look like when the spindle and bearing is together

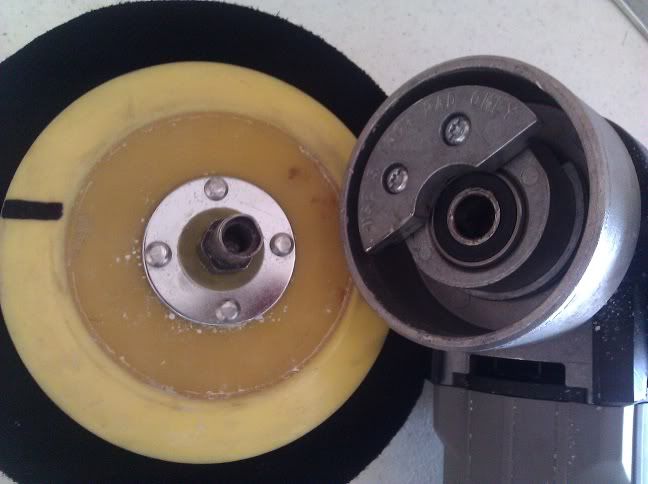

This is what it looked like flying off my PC and scratching the car!

Spindle off the backing plate

I was too upset to take any picture of the damage on the car

Old PC 7424

What it should look like when the spindle and bearing is together

This is what it looked like flying off my PC and scratching the car!

Spindle off the backing plate

I was too upset to take any picture of the damage on the car