Just to chime in...

Keep in mind these to rotary buffers are two different categories of machines,

Full size

Compact

I touch on what the key point is between these two categories in my Bumblebee thread here,

Bumblebee - Testing out the NEW DeWALT DWP849X

For some reason when I look at the new

DWP849X I think of

Bumblebee

1949 Chevy Sedan Delivery

And here's

post #45, the entire thread is actually a how-to for buffing out a car using a rotary buffer with lots of tips and techniques. I probably have at least 4-5 hours of photography work inserted into this thread with text to explain things. FWIW

Note the text in blue, I think this makes Dave's point about why he likes a full size rotary buffer for the style of buffing he does.

As Mike has mentioned in one of his posts in this thread, the PE-14 is smooth, quiet running, well balanced and comfortable to use.

I do like the tool for those reasons but I thought I was pretty clear about the tool not fitting in well with "my own style" of compounding which is to keep my foam pads (which measure at about 7" in diameter) primed, as flat to the paint as possible (as in the entire face of the pad spinning flat on the paint) with a good amount of pressure applied.

It's my style and it produces nice results fast. The PE-14 just doesn't have the power to support my style of polishing for any extended period of time like the 9227 does.

Begin post #45

Very nice review Mike. That Flex sure does have plenty of good things going for it. The only real negative seems to be the high initial cost.

Quality never costs money it makes money...

The one remaining unanswered question I have is, can it be used for high volume paint correction work? The DeWalt looks heavy duty, like it was made for high volume work. Can the same be said of the Flex?

According to Flex the answer is yes. They state that up to an 8" diameter pad can be used with the Flex PE14 but I prefer to stay a little smaller especially for wool pads.

More reciprocating mass creates more torque

My personal thoughts are that if you're going to be buffing out sanding marks all day long or removing oxidation from large boats all day long that a full size rotary buffer would be a better choice. The gears are bigger in size as are the rest of the components in a full size rotary buffer and I think having more reciprocating mass creates more torque and this is something you would want if you're going to be doing heavy compounding and polishing with full size pads, (8" and larger), 6 days a week.

It does look beautiful indeed. No way i could swing that kinda cash for a rotary right now but its nice to have some input as to a comparison of the 2 polishers.

Quick question...what major differences do you see between the PE and the 3403 flex rotary?

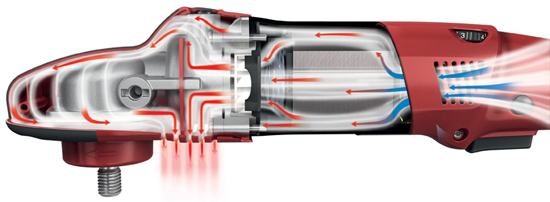

First major difference is the new Flex PE14 has the design that flushes the tool with air to help the tool run cooler.

More information and a video on this page,

The New FLEX PE14-2-150 Rotary Buffer

Also to those who were interested in the 3" pads...AG does sell some...they are made by Griots...of course!

Correct and these work well too. You can see them in action here,

Pictures + Video of 1932 Ford Highboy Extreme Makeover

The 3" pads I'm using are some prototypes...

I must say that detailing cart looks super sweet....another wish list item...grrr....i wont buy it till i finally have a stationary place to do my detailing...too bulky for mobile detailing..im 25..i can still lean over to clean my pads LOL.

The cart is nice, it makes using the pad washer a lot easier plus gives you plenty of storage space for other related tools.

After about 6 hours of running both rotary buffers here's what I think, the new DeWALT is a great rotary buffer especially for the price. The 600 RPM low range is the most valuable feature. I also really like the rubber bumpers on the back side that enable you to set it down on a polished fender or hood without scratching the paint.

Apples to Oranges

Comparing the Flex PE14 to any of the full size DeWALT rotary buffers, or the Makita, or any other brand of full size rotary buffers is like comparing apples to oranges in that the Flex PE14 is a true compact rotary buffer and falls into the

Compact Size category, while the DeWALT DWP849X falls into the

Full Size category for rotary buffers.

Makita 9227C vs DeWALT DWP849X

A better comparison would be to compare the Makita 9227C with the DeWALT DWP849X as they are much more similar and my guess is that DeWALT introduced this new model to compete against the Makita rotary buffer. Both of these buffers, the Makita or the DeWALT would be great choices. I've always been a fan of Makita rotary buffers if for no other reason because I used one for years until it finally wore out having purchased it new in 1988.

The best of both worlds

In a perfect world a person would have at least

two rotary buffers, a

full size working dog for doing all of the

grunt work and a

compact, light-weight rotary buffer for when you need to do surgical

precision work. This way you can use the one that best fits the job at hand.

The compact size and low weight of the Flex PE14 plus the 600 RPM range are the features I'm most attracted to. It's

light weight and

small size make it really easy to control when doing intricate work. Perhaps we'll see the introduction of other compact, lightweight rotary buffers into the future.

After the compounding the upper half of the 1949 Sedan Delivery, I just switched over to the Flex PE14 due to the light weight and compact size features. I could have used either for the rest of the job by my preference was for the easiest tool to work with as this streetrod has a lot of real-estate to buff.

Here's some pictures to show relative sizes...

The two Flex rotary buffers on the left are in the

Compact category while the other 4 rotary buffers are in the Full Size category. Comparing the compacts with the full size rotary buffers can be done but it trends towards the comparing applies to oranges analogy as in person and in use you can tell right away when you switch from a full size to a compact or visa-versa.

The new DeWALT DWP849X is wider and more bulky like the other full size rotary buffers in these pictures.

You can that the Flex is more narrow from top to bottom...

END OF POST #45

As I said earlier it does have a place in my arsenal of tools if I need to do what Mike calls "surgical detailing" using 3 and 4 inch pads.

A compact, that is small, non-bulky rotary buffer is the best way to go for intricate and delicate work.

You can use small pads and extension on full size rotary buffers but until you've used BOTH types of rotary buffers like this you will never be able to appreciate the

finesse of a compact, lightweight rotary buffer for doing surgical buffing.

Example - Working out sanding marks on a Blown 1934 Ford Pickup. I, and I'm certain all of you would not want to make a mistake while sanding or using a rotary buffer on a paint job like this because the repair would be expensive.

Blown 1934 Ford Pick-up - Show Car Makeover - Modeled by Kristin

Meanwhile I tackled the random, isolated deeper scratches, some by dampsanding with Meguiar's #3000 Finishing Discs and some just using the new Optimum 3" Microfiber Pads on a Flex PE 14 Rotary Buffer using Pinnacle Advanced Swirl Remover.

In a perfect world, and when your budget allows, having both a quality Full Size rotary buffer and a Compact size rotary buffer would enable you to pick and choose the best tool for the specific job you're undertaking.

rops:

rops: