LuxuryMobile

New member

- Feb 12, 2009

- 1,532

- 0

2004 Cadillac XLR

Client contacted us to get the paint on this Cadillac looking how it should. Teamed up with Brett for this one. Although the car is several years old it only has 12,000 miles. The paint on this was BAD. A lot of automatic washes, Brillo pads scrubs, etc. By no means was or has this paint ever been properly cared for.

After some test spots we dialed in a two step process that gave us the results that we were looking for to fit the client’s budget. The Meg MF Cutting pads were primed with D300 and M105 would be used at the start of each section. 5 pads were used during the cutting stage. We followed this up with M205 on a white pad to restore gloss and further refine the finish. Smaller pads were used to reach more difficult areas. Some defects were too deep to safely remove and the budget wouldn’t allow for a %100 correction. Overall most of the paint finished to about 85-90%. The client is very interested in having the car Opti-Coated in the near future, but for now Fuzion was used. Wheels were sealed with DP Poli Coat. Some of the pictures show lenting from the towels that were used.

Interior was also done using APC+, Meg 40, Meg Leather Conditioner, Meg Glass Cleaner. Interior was pretty clean too, so didn’t bother with pictures.

Pictures Upon Arrival, in the sun

Real swirled up, but not too “dirty”

Inside of the wheels needed some attention

The paint was beading pretty well from some type of product still sitting on the surface

A foam gun mixture of APC and Meg Body Solvent were used to wash the surface to remove any product to reveal the true

paint condition.

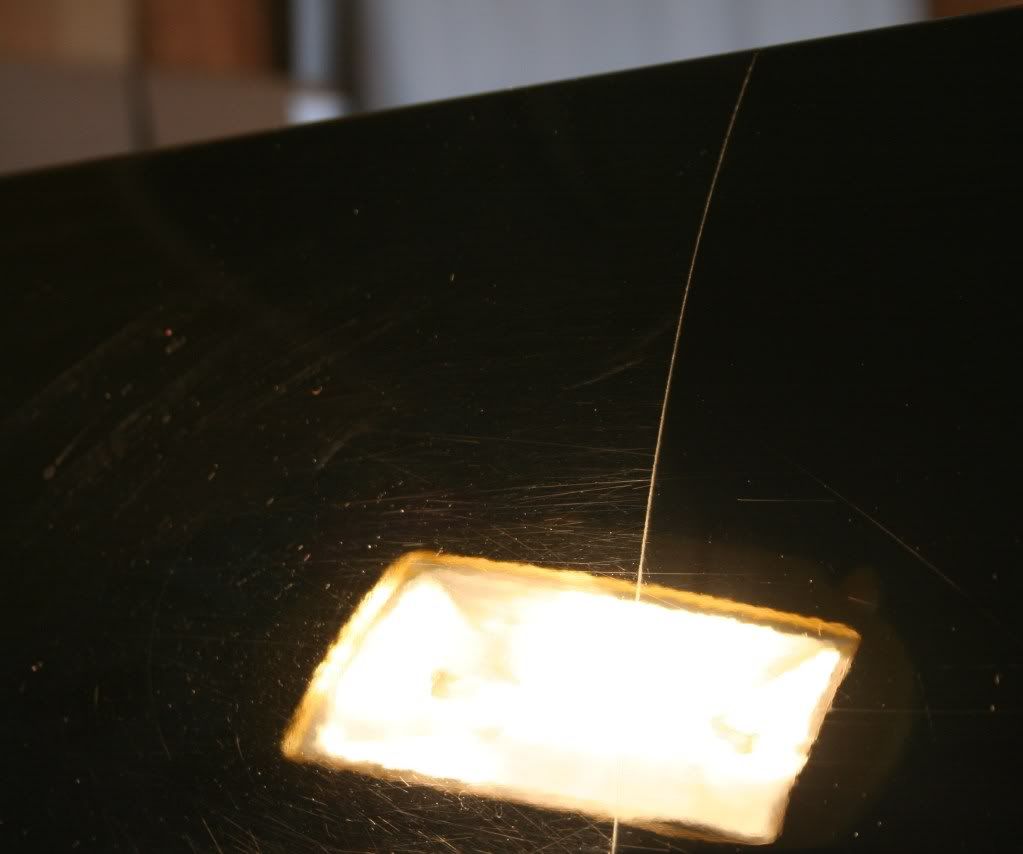

50/50 of wax removed on trunk lid

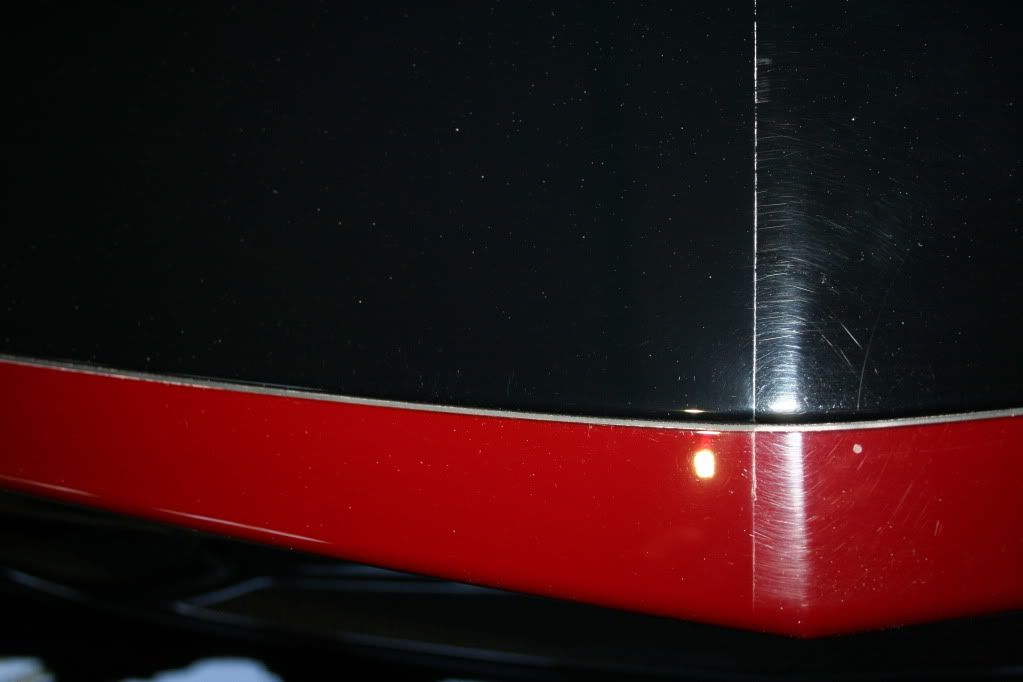

Wax Removed, better look at the true condition of the paint

Client contacted us to get the paint on this Cadillac looking how it should. Teamed up with Brett for this one. Although the car is several years old it only has 12,000 miles. The paint on this was BAD. A lot of automatic washes, Brillo pads scrubs, etc. By no means was or has this paint ever been properly cared for.

After some test spots we dialed in a two step process that gave us the results that we were looking for to fit the client’s budget. The Meg MF Cutting pads were primed with D300 and M105 would be used at the start of each section. 5 pads were used during the cutting stage. We followed this up with M205 on a white pad to restore gloss and further refine the finish. Smaller pads were used to reach more difficult areas. Some defects were too deep to safely remove and the budget wouldn’t allow for a %100 correction. Overall most of the paint finished to about 85-90%. The client is very interested in having the car Opti-Coated in the near future, but for now Fuzion was used. Wheels were sealed with DP Poli Coat. Some of the pictures show lenting from the towels that were used.

Interior was also done using APC+, Meg 40, Meg Leather Conditioner, Meg Glass Cleaner. Interior was pretty clean too, so didn’t bother with pictures.

Pictures Upon Arrival, in the sun

Real swirled up, but not too “dirty”

Inside of the wheels needed some attention

The paint was beading pretty well from some type of product still sitting on the surface

A foam gun mixture of APC and Meg Body Solvent were used to wash the surface to remove any product to reveal the true

paint condition.

50/50 of wax removed on trunk lid

Wax Removed, better look at the true condition of the paint