Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 8

5.5" SUPER THIN FOAM PAD OPTIONS for your Dual Action Polisher

Super thin 5.5" foam buffing pads

The primary benefit to super thin foam pads is that free spinning orbital polishers are able to rotate and oscillate these pads better than thick pads.

What does this mean to you?

You can compound and polish paint to perfection faster than ever before when using orbital polishers like the Porter Cable 7424XP or the Griot's Garage 6" DA polisher.

Currently Autogeek carries three brands of super thin foam pads,

From left to right

Lake Country 5.5" ThinPro foam pads

Griot's Garage BOSS 5.5" foam pads

Meguiar's 5.5" foam discs

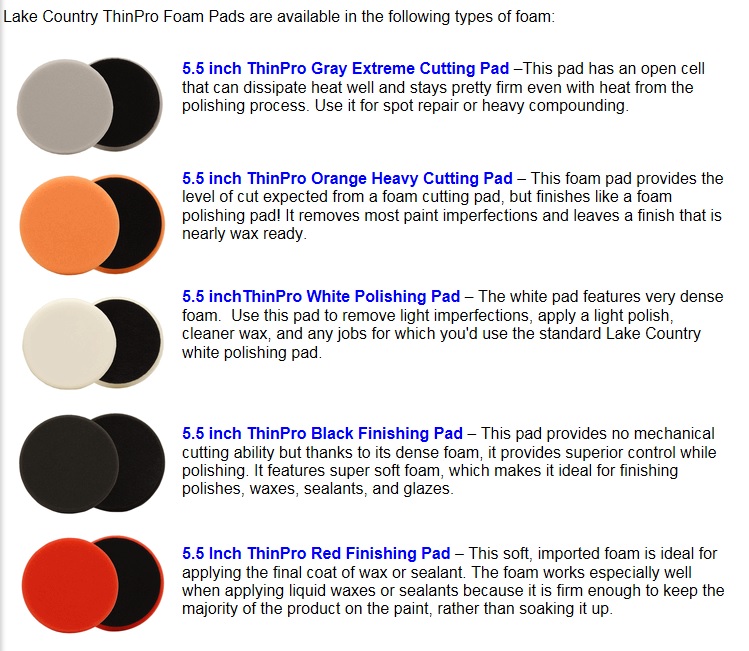

Lake Country 5.5" ThinPro foam pads

Griot's Garage BOSS 5.5" foam pads

The Griot's BOSS foam pads are unique from the rest in that they have a hole in the center of the pad.

Meguiar's 5.5" foam discs

Thinner, smaller pads rotate and oscillate easier simply because they have less mass. Not only do they rotate better because they have less mass but since there is less mass pad saturation is not as influential of a factor as it is for thick pads on dual action polishers.

On Autogeek.com

It's a good idea to purchase a backing plate from the same company you purchase your pads so that way you know you're the velcro attachment system for the pads and the backing plate will match.

Lake Country

Lake Country ThinPro Foam Pad System 5.5 inch

Lake Country 5" Dual-Action Hook & Loop Flexible Backing Plate

Griot's

5.5 Inch BOSS Pads

6.5 Inch BOSS Pads

Griots Garage 5 Inch Vented Orbital Backing Plate

Meguiar's

Meguiars 5 Inch DA Foam Discs

Meguiars Soft Buff DBP5 DA Polisher 5 inch Backing Plate

Need a dual action polisher?

Below are the simple, safe and easy to learn how to use dual action polishers available at Autogeek.com

These tool all offer an 8mm orbit stroke length and work best with the thin pads and matching backing plates shared in this article. These tools all operate the same way just some of them use a longer body style for those that prefer a traditional shaped polisher.

Note: Some polishers are available with a heavy duty 25' electrical cord pre-wired into the tool. These are exclusive to Autogeek and when purchased through Autogeek you get the same factory warranty as the version with the stock electrical cord. The longer cord enables you to safe time because you don't have to mess around with extension cords coming un-plugged. The 25' cords also use the recommended heavy gauge wire to protect the tools electronics. Using an extension cord that uses light gauge wiring can damage your tool and void your warranty. Wiring in your own extended cord will void your warranty.

Porter Cable 7424XP - Standard cord

Porter Cable 7424XP - HD Cord - 25' Heavy Duty Cord already pre-wired

Griot's Garage 6" ROP - Standard cord

Griots Garage 6 Inch Heavy Duty Random Orbital Polisher - HD Cord - 25' Heavy Duty Cord already pre-wired

Meguiars MT300 Dual Action Polisher

Chemical Guys TORQ 10FX Random Orbital Polisher

Shurhold DA Polisher

Super thin 5.5" foam buffing pads

The primary benefit to super thin foam pads is that free spinning orbital polishers are able to rotate and oscillate these pads better than thick pads.

What does this mean to you?

You can compound and polish paint to perfection faster than ever before when using orbital polishers like the Porter Cable 7424XP or the Griot's Garage 6" DA polisher.

Currently Autogeek carries three brands of super thin foam pads,

From left to right

Lake Country 5.5" ThinPro foam pads

Griot's Garage BOSS 5.5" foam pads

Meguiar's 5.5" foam discs

Lake Country 5.5" ThinPro foam pads

Griot's Garage BOSS 5.5" foam pads

The Griot's BOSS foam pads are unique from the rest in that they have a hole in the center of the pad.

Meguiar's 5.5" foam discs

Thinner, smaller pads rotate and oscillate easier simply because they have less mass. Not only do they rotate better because they have less mass but since there is less mass pad saturation is not as influential of a factor as it is for thick pads on dual action polishers.

On Autogeek.com

It's a good idea to purchase a backing plate from the same company you purchase your pads so that way you know you're the velcro attachment system for the pads and the backing plate will match.

Lake Country

Lake Country ThinPro Foam Pad System 5.5 inch

Lake Country 5" Dual-Action Hook & Loop Flexible Backing Plate

Griot's

5.5 Inch BOSS Pads

6.5 Inch BOSS Pads

Griots Garage 5 Inch Vented Orbital Backing Plate

Meguiar's

Meguiars 5 Inch DA Foam Discs

Meguiars Soft Buff DBP5 DA Polisher 5 inch Backing Plate

Need a dual action polisher?

Below are the simple, safe and easy to learn how to use dual action polishers available at Autogeek.com

These tool all offer an 8mm orbit stroke length and work best with the thin pads and matching backing plates shared in this article. These tools all operate the same way just some of them use a longer body style for those that prefer a traditional shaped polisher.

Note: Some polishers are available with a heavy duty 25' electrical cord pre-wired into the tool. These are exclusive to Autogeek and when purchased through Autogeek you get the same factory warranty as the version with the stock electrical cord. The longer cord enables you to safe time because you don't have to mess around with extension cords coming un-plugged. The 25' cords also use the recommended heavy gauge wire to protect the tools electronics. Using an extension cord that uses light gauge wiring can damage your tool and void your warranty. Wiring in your own extended cord will void your warranty.

Porter Cable 7424XP - Standard cord

Porter Cable 7424XP - HD Cord - 25' Heavy Duty Cord already pre-wired

Griot's Garage 6" ROP - Standard cord

Griots Garage 6 Inch Heavy Duty Random Orbital Polisher - HD Cord - 25' Heavy Duty Cord already pre-wired

Meguiars MT300 Dual Action Polisher

Chemical Guys TORQ 10FX Random Orbital Polisher

Shurhold DA Polisher