Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any PC 7424xp cord mod?

- Thread starter Gussi41

- Start date

- Thread starter

- #3

Thanks for the reply. I opened the PC and it's completely different.

I noticed that the black wire is grouped with other wires in a quick connect housing, three total, and the white wire terminates in the variable-speed dial housing.

In each case I'm not sure if I should/could pull it out and even if I could, being that it's 18 gauge, would the 16 gauge wire fit in.

My first thought is to leave both wires terminated and splice my new connection, similar to the Rupes LHR15ES Mod, but I'd prefer using crimp-on butt connectors.

Anyone see any issues in doing that? If so, any better ideas or advice.

Gussi

I noticed that the black wire is grouped with other wires in a quick connect housing, three total, and the white wire terminates in the variable-speed dial housing.

In each case I'm not sure if I should/could pull it out and even if I could, being that it's 18 gauge, would the 16 gauge wire fit in.

My first thought is to leave both wires terminated and splice my new connection, similar to the Rupes LHR15ES Mod, but I'd prefer using crimp-on butt connectors.

Anyone see any issues in doing that? If so, any better ideas or advice.

Gussi

JSou

New member

- Dec 17, 2012

- 1,635

- 0

Photecs

New member

- Feb 18, 2014

- 127

- 0

http://www.autogeekonline.net/forum...-polishers/69919-harbor-freight-cord-mod.html

Ah! I just posted the same thing....

Took me a bit to find it. So the xp different then this PC shown?

Ah! I just posted the same thing....

Took me a bit to find it. So the xp different then this PC shown?

- Thread starter

- #7

I didn't know the xp was any different then the original 7424... I have it on order, and just went out and bought a 25' 14g extension to wire it up.

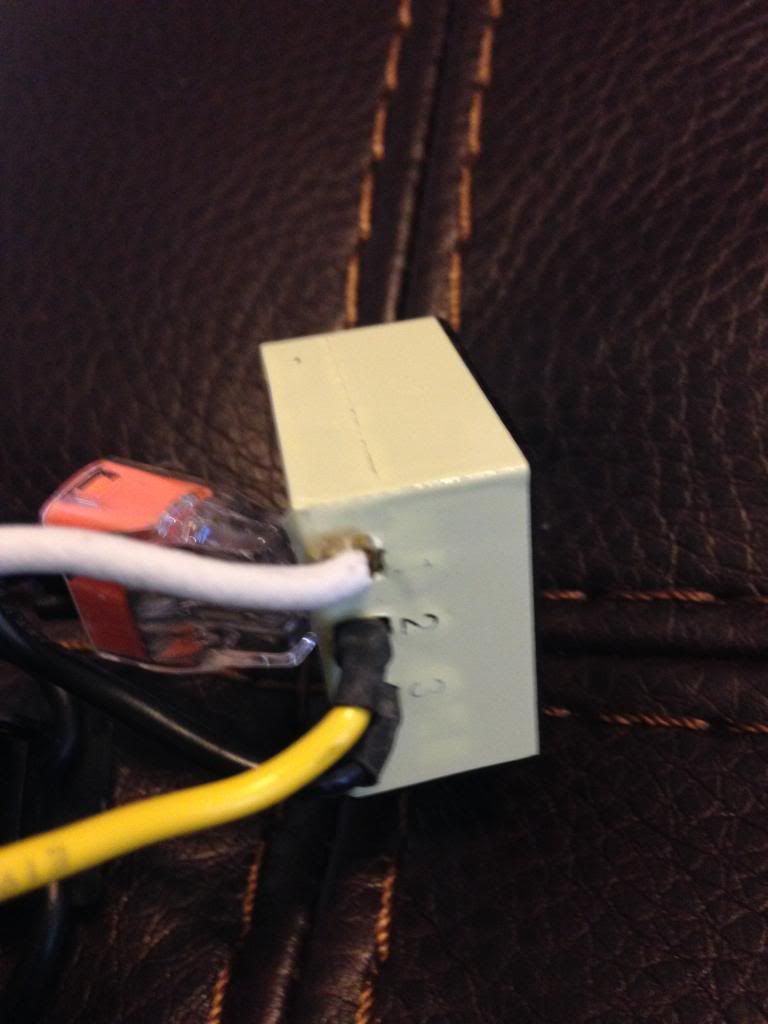

Can you take a photo of what we're looking at?

Here you go.

Photecs

New member

- Feb 18, 2014

- 127

- 0

WOW, that is much different then I thought it would be... thanks for the pics.

Really, by just looking at that, I don't see any other way then to cut/soldier together the new wire. Snip th black and whites, and soldier the new 25' extension cable to them... cover it up with shrink tube.

There's no way i'm going to mess around with that white box!

Really, by just looking at that, I don't see any other way then to cut/soldier together the new wire. Snip th black and whites, and soldier the new 25' extension cable to them... cover it up with shrink tube.

There's no way i'm going to mess around with that white box!

- Thread starter

- #12

Splice in, solder, heat shrink, done. Haha.

Not anything different compared to any other machine. Two power wires as expected,

Thanks bro, I'll be doing just that.

My original concern was splicing different gauge wires, but after some research I've learned that it's ok to go from source 18 awg to 16 awg, but not vice-versa.

Also, realized after the fact that you're the arthur of the "Rupes LHR15ES!!!" mod. Excellent instructions.

Gussi

Haha, thanks.

And yeah you wouldn't want to do it backwards, but I'm glad you've gotten it figured out.

I had no idea though, that the PC was 18ga from factory. Crazy.

And yeah you wouldn't want to do it backwards, but I'm glad you've gotten it figured out.

I had no idea though, that the PC was 18ga from factory. Crazy.

Thanks bro, I'll be doing just that.

My original concern was splicing different gauge wires, but after some research I've learned that it's ok to go from source 18 awg to 16 awg, but not vice-versa.

Also, realized after the fact that you're the arthur of the "Rupes LHR15ES!!!" mod. Excellent instructions.

Gussi

lawrenceSA

New member

- Feb 7, 2012

- 1,713

- 0

Please excuse my ignorance, but what does modifying the cord do?

What is the benefit?

What is the benefit?

Please excuse my ignorance, but what does modifying the cord do?

What is the benefit?

No need to carry an extension cord with you.

lawrenceSA

New member

- Feb 7, 2012

- 1,713

- 0

Ah I see. Ok thanks.

I seem to recall reading somewhere that the length and gauge of the cord will effect the power of the machine.

Is this correct?

I assume then the cord should be as short as practically possible? But how do I know what gauge wiring to use?

Any help would be most welcomed.

TIA

I seem to recall reading somewhere that the length and gauge of the cord will effect the power of the machine.

Is this correct?

I assume then the cord should be as short as practically possible? But how do I know what gauge wiring to use?

Any help would be most welcomed.

TIA

BobbyG

New member

- Dec 29, 2009

- 13,211

- 0

Ah I see. Ok thanks.

I seem to recall reading somewhere that the length and gauge of the cord will effect the power of the machine.

Is this correct?

I assume then the cord should be as short as practically possible? But how do I know what gauge wiring to use?

Any help would be most welcomed.

TIA

Generally speaking you are correct but if you're using an extension cord you'll also suffer from the same affects...load and resistance...

The longer the run of wire, the more resistance, and thus, more heat. So how does this effect you? Well, power tools draw a certain amount of amperage to run both correctly and efficiently.

This electrical load may be too great for the size of extension cord it is attached to. Because of wire size, resistance of the wire, and the voltage drop due to the distance, these variables can damage both extension cords and the power tools that are connected to them.

Voltage drop in the cord often doesn't allow the power tools to run at full speed. This causes them to heat up and often inflicts damage to them. Wiring inside the tools can melt as well as inflicting damage to the contacts. As the power tools heat up, so does the extension cords that they are connected to. That in turn leads to circuit breakers tripping, often due to a heating up of the breaker and/or overloading of the circuit breaker.

This is why proper wire sizing is important...

lawrenceSA

New member

- Feb 7, 2012

- 1,713

- 0

Thanks for the information Bobby - much appreciated. I know have a much better understanding of this.

How does one then calculate the ideal length (presumably as short as practically possible) and gauge of cord to be used in order to ensure you are not stressing the machine unnecessarily?

How does one then calculate the ideal length (presumably as short as practically possible) and gauge of cord to be used in order to ensure you are not stressing the machine unnecessarily?