Hey all,

I'm having some problems with removing Pinnacle Black Label Surface Polish in preparation for Black Label Diamond Surface Coating application. Now, I am a former detailer, but I have been out of the business since '07, and haven't applied a coating before. Lots has happened in 7 years! I would imagine the surface needs to be free of any and all contaminants (including dust and microfiber lint) before application, or the coating would likely trap those contaminants within or underneath the coating layer, correct? With the surface polish not removing completely, I'm at a loss for how to proceed.

I've noticed two distinct issues so far:

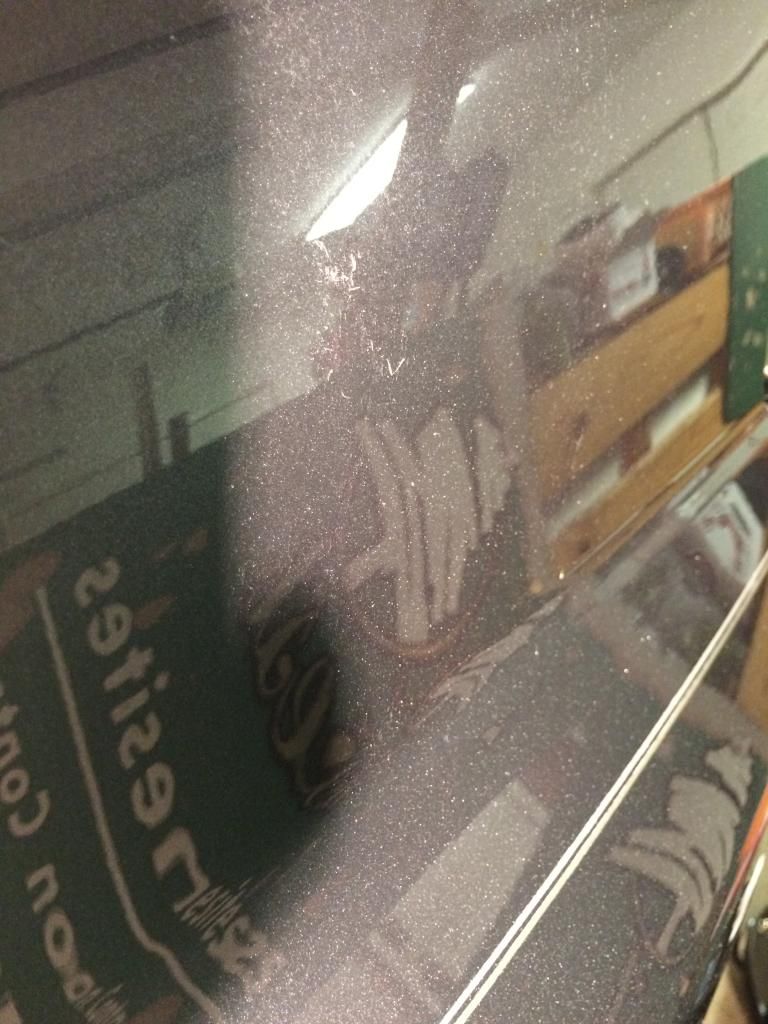

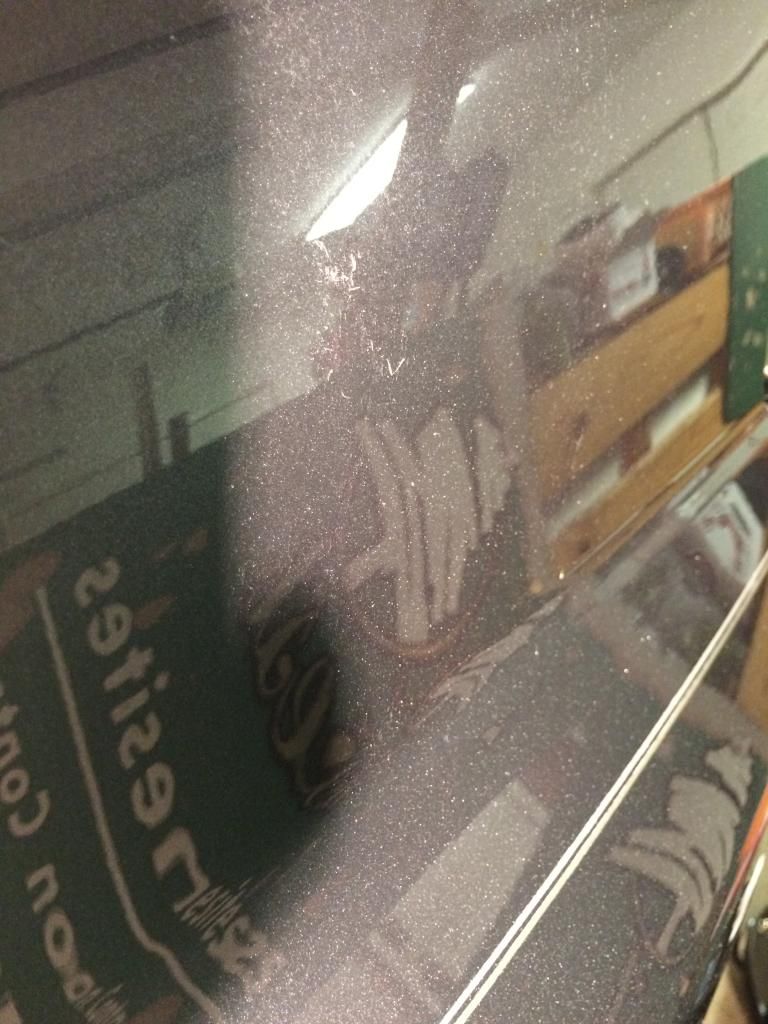

First the polish seems to "clump" into long, almost rolled bunches at the edges of my microfiber wiping zone towards the end of the removal wipedown... below are two pictures, from different spots:

This stuff will wipe off with micro, but is a pain in the rear, as it wants to redeposit on random areas of paint all the time. Relatively deep nap towels (Wolfgang Concours edgeless, bought on BOGO) do a decent job of containment, but it's taking one full towel per 1/2 panel! I don't have enough on hand to keep up!

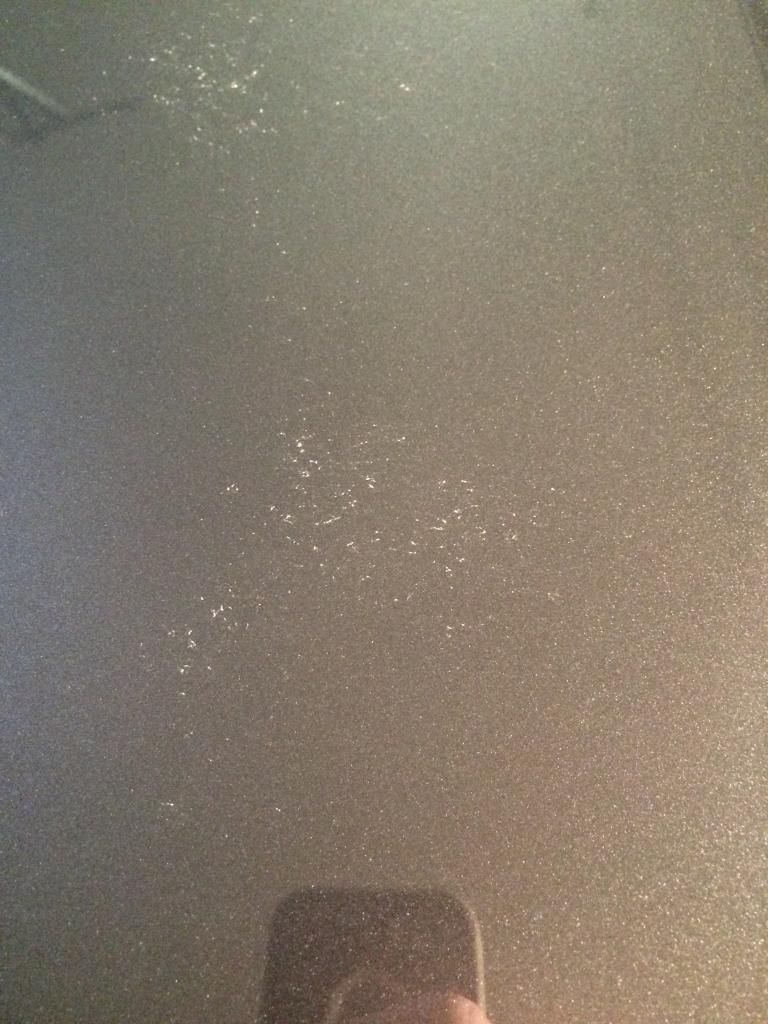

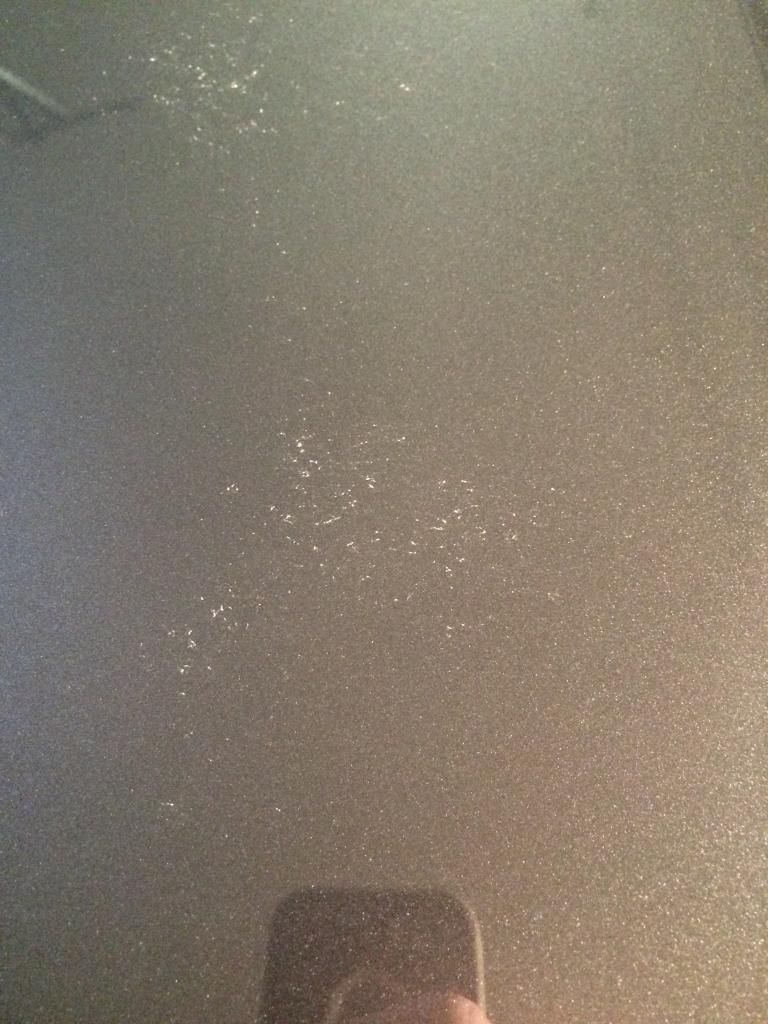

The second big problem is this:

Areas are forming on the panel where the product is impossible to remove by microfiber alone (unless using a dangerous amount of pressure). I can wipe them off with my palm or fingertip, and I immediately notice the same kind of sticky clumps.

It looks as though both are a collection of microfiber lint bound together by a gummy (but not necessarily sticky) substance. I'm assuming that the gummy substance is the polish, and not underlying product like Meg's UP residue being stripped. But I could be wrong... is this the way it reacts to an underlying product? I tried applying by machine to strip a somewhat stubborn LSP towards the beginning of the process (after washing and before claying) and got the same results, which I chalked up to overworking with the polisher. I decided to hand apply since I don't have a decent DA polisher with variable speed (anyone looking to donate one to a good cause? ).

).

I've tried applying the stuff with well folded microfiber towels, foam pads, terry pads, microfiber pads, using distilled water spray on the panel before and/or after, using only one "drop" of product per panel, using a large dollop per panel, wiping on then literally wiping off ... all with similar results in the end. The microfiber pad applicator with a spritz of water before removal seems to give the best results, but still leaves a lot of elbow grease behind for me to remove it all... and I'm still not certain ALL of it is gone.

Needless to say, this doesn't sound at all like the product description! I can't do this on an entire car... not to mention spending days of work only to get a failing coating if there is residual product left behind.

I did read this article, and associated threads, but had no luck with their suggestions:

http://www.autogeekonline.net/forum/auto-detailing-101/75875-dp-prep-polish-vs-pbl.html

Just to summarize my conditions and procedures:

All work was done in a closed garage, with around 45% to 50% RH, at around 70 to 75 degrees.

Car is a new 2014 Honda Accord, silver/grey metallic color. Paint was in extremely poor condition for a new car (NEVER buy a car at dusk... I learned the hard way). Lots of overspray, lots of rail dust (hidden in the grey metallic), and surface roughness (not sure if it was just overspray, but the paint was extremely "grabby" towards micro at first).

Did a wash, LSP strip, Iron-X, Nanoskin fine sponge with glide 7:1 (which gave me dense RIDS, GRRR, not happy with that!), with Meg's UC, and Meg's UP on the test panel.

The test panel was actually my trunk lid, as it was at a convenient height, and the worst damaged.

I made sure to shake the bottle of SCP well, and even tried some polish direct from the bottle, bypassing the pump. No dice.

Perhaps it's a problem with my particular batch, or individual bottle I received. Maybe I just got old stock?? Although I would imagine this top quality stuff would have a 7 year plus shelf life. Is it simply a problem with my microfiber towels shedding too much? I've been using old (5 to 8 years old, when they still had nice piped edges) Meg's supreme shine micros for the initial wipedown, followed by a Wolfgang for the follow-up wipes. Do all micro. towels start degrading and shedding with age perhaps? Even on the spots that get "clean-er", there are still around 10 small bits of microfiber remaining... I can't seem to get it any cleaner than that! Is there something else that I'm missing?

Can't wait to finally get that rewarding experience worthy of Black Label!! :dblthumb2:

-Mike

I'm having some problems with removing Pinnacle Black Label Surface Polish in preparation for Black Label Diamond Surface Coating application. Now, I am a former detailer, but I have been out of the business since '07, and haven't applied a coating before. Lots has happened in 7 years! I would imagine the surface needs to be free of any and all contaminants (including dust and microfiber lint) before application, or the coating would likely trap those contaminants within or underneath the coating layer, correct? With the surface polish not removing completely, I'm at a loss for how to proceed.

I've noticed two distinct issues so far:

First the polish seems to "clump" into long, almost rolled bunches at the edges of my microfiber wiping zone towards the end of the removal wipedown... below are two pictures, from different spots:

This stuff will wipe off with micro, but is a pain in the rear, as it wants to redeposit on random areas of paint all the time. Relatively deep nap towels (Wolfgang Concours edgeless, bought on BOGO) do a decent job of containment, but it's taking one full towel per 1/2 panel! I don't have enough on hand to keep up!

The second big problem is this:

Areas are forming on the panel where the product is impossible to remove by microfiber alone (unless using a dangerous amount of pressure). I can wipe them off with my palm or fingertip, and I immediately notice the same kind of sticky clumps.

It looks as though both are a collection of microfiber lint bound together by a gummy (but not necessarily sticky) substance. I'm assuming that the gummy substance is the polish, and not underlying product like Meg's UP residue being stripped. But I could be wrong... is this the way it reacts to an underlying product? I tried applying by machine to strip a somewhat stubborn LSP towards the beginning of the process (after washing and before claying) and got the same results, which I chalked up to overworking with the polisher. I decided to hand apply since I don't have a decent DA polisher with variable speed (anyone looking to donate one to a good cause?

I've tried applying the stuff with well folded microfiber towels, foam pads, terry pads, microfiber pads, using distilled water spray on the panel before and/or after, using only one "drop" of product per panel, using a large dollop per panel, wiping on then literally wiping off ... all with similar results in the end. The microfiber pad applicator with a spritz of water before removal seems to give the best results, but still leaves a lot of elbow grease behind for me to remove it all... and I'm still not certain ALL of it is gone.

Needless to say, this doesn't sound at all like the product description! I can't do this on an entire car... not to mention spending days of work only to get a failing coating if there is residual product left behind.

I did read this article, and associated threads, but had no luck with their suggestions:

http://www.autogeekonline.net/forum/auto-detailing-101/75875-dp-prep-polish-vs-pbl.html

Just to summarize my conditions and procedures:

All work was done in a closed garage, with around 45% to 50% RH, at around 70 to 75 degrees.

Car is a new 2014 Honda Accord, silver/grey metallic color. Paint was in extremely poor condition for a new car (NEVER buy a car at dusk... I learned the hard way). Lots of overspray, lots of rail dust (hidden in the grey metallic), and surface roughness (not sure if it was just overspray, but the paint was extremely "grabby" towards micro at first).

Did a wash, LSP strip, Iron-X, Nanoskin fine sponge with glide 7:1 (which gave me dense RIDS, GRRR, not happy with that!), with Meg's UC, and Meg's UP on the test panel.

The test panel was actually my trunk lid, as it was at a convenient height, and the worst damaged.

I made sure to shake the bottle of SCP well, and even tried some polish direct from the bottle, bypassing the pump. No dice.

Perhaps it's a problem with my particular batch, or individual bottle I received. Maybe I just got old stock?? Although I would imagine this top quality stuff would have a 7 year plus shelf life. Is it simply a problem with my microfiber towels shedding too much? I've been using old (5 to 8 years old, when they still had nice piped edges) Meg's supreme shine micros for the initial wipedown, followed by a Wolfgang for the follow-up wipes. Do all micro. towels start degrading and shedding with age perhaps? Even on the spots that get "clean-er", there are still around 10 small bits of microfiber remaining... I can't seem to get it any cleaner than that! Is there something else that I'm missing?

Can't wait to finally get that rewarding experience worthy of Black Label!! :dblthumb2:

-Mike