Hmm... thought I posted this here on AG but couldn't find it. :dunno: It's on DW and AU.

Ah well, even though it doesn't relate to 3" backing plates, it does relate to the DA Microfiber Discs:

To maximize cutting and finishing potential of the Meguiar's DA Microfiber discs, I cut down larger plate to better fit the discs. Cut down backing plates work very well for foam pads, too.

It's my opinion that in order to mechanically optimize the DA Discs, the pad must be supported to the outer edge. Since Meguiar's does not currently offer a backing plate exactly the same diameter, I cut down a Meguiar's W68DA plate to the same size. It cuts very easy- a pair of scissors will work.

I used a carpet razor knife to cut these plates, then sanded the edges using 80 grit and then 150 grit sandpaper. The studs were chucked in a handheld electric drill, and I pushed the knife into the foam as the plate was spinning. Then, I sanded in the same manner. Make sure to wear eye protection!

This is the Meguiar's W68DA, backside shot:

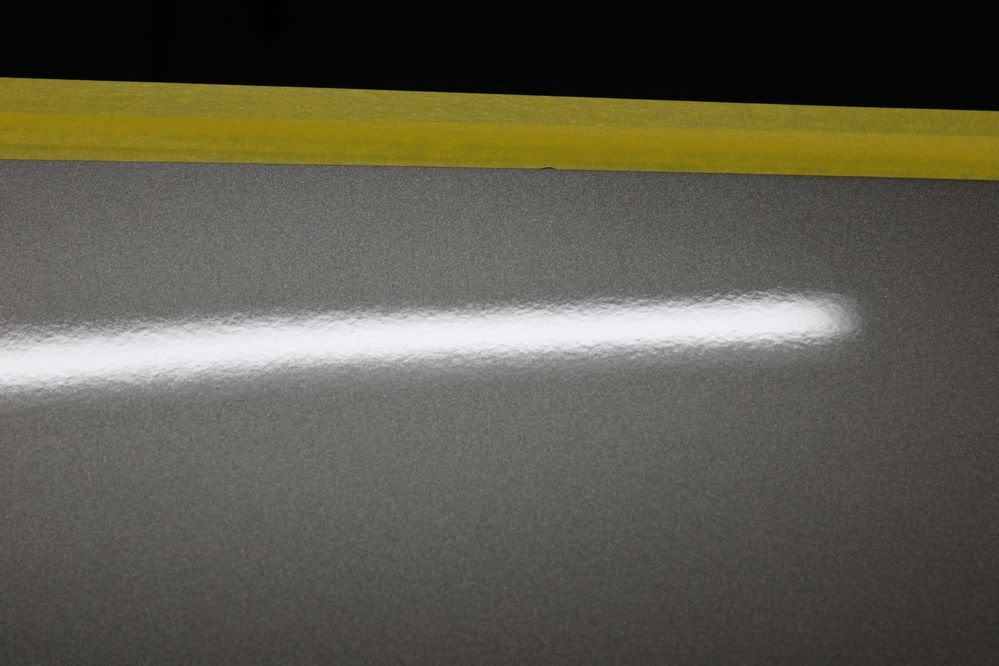

This is the Meguiar's W68DA, face shot:

This is the Meguiar's W68DA, backside shot:

This is the Meguiar's W68DA, face shot:

Notice that the Velcro® does not cover the entire plate.

It was designed for the 2.0 Soft Buff pads.

I cut the pad down to within a couple millimeters of the Velcro®.

The cut down version is set atop the uncut version:

This is how it looks once the backing plate is mounted to the disc:

This is the recommended W67DA set atop the cut down W68DA:

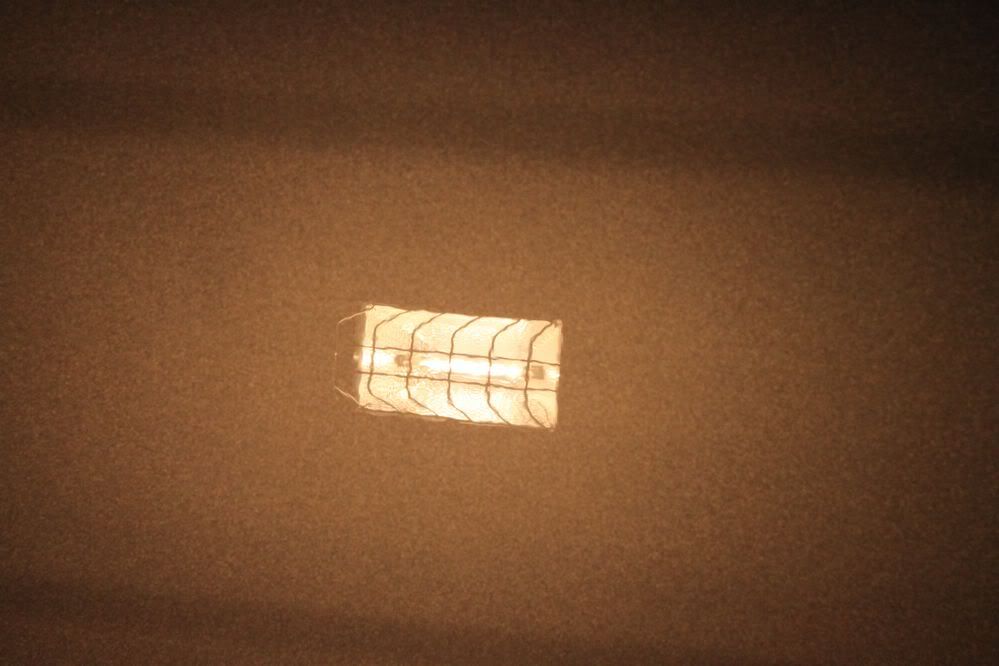

I used a Mirka 106GG because I had some in stock, and they have proven to be bulletproof for me:

Mirka 106GG:

The cut down version set atop the uncut version:

This is how it looks once the backing plate is mounted to the disc:

Obviously, if you use the stiff plate, you'll need to be careful on curved surfaces. The W68DA is soft, so even it it happened to contact a surface accidentally, damage potential would be comparatively low.

But!- for leveling, severe defect removal, for defect or sanding mark removal next to body trim, etc., and final polishing, the discs have delivered much better results for me when they are supported to the outer edge. My best guess would be somewhere in the 30% improved range for cutting potential, and an immeasurable amount for finish polishing.

Good luck!