I have read here many times that prior to applying a paint sealant (Wolfgang Deep Gloss in this case), a paint prep is used, (N-914 in this case) to remove any residuals left on the vehicle.

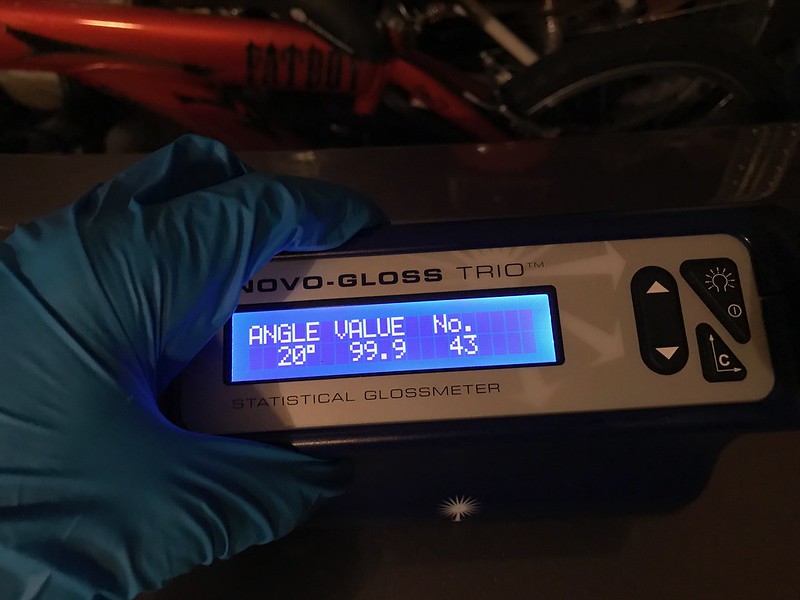

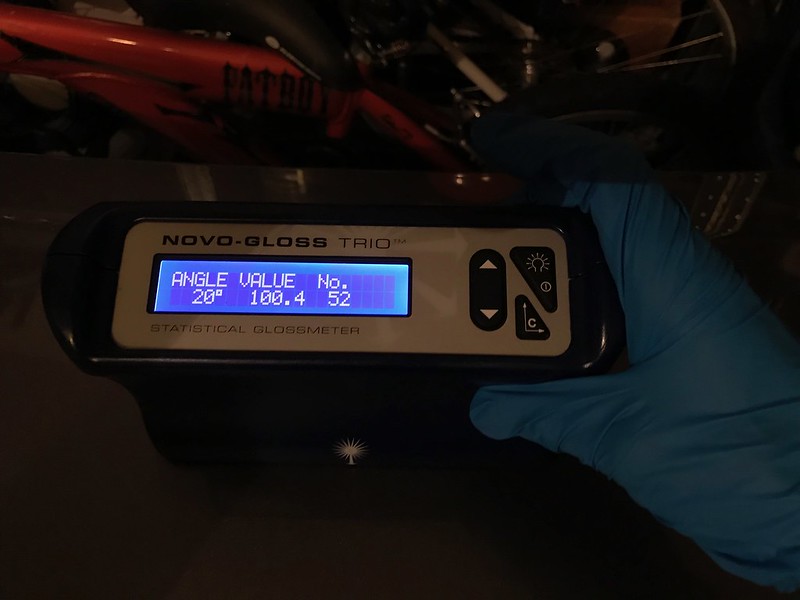

My question being........ Does the prep process remove any of the gloss I achieved during my cut and polish steps? I used 3D HD products and got great results, but am wondering if the N-914 mix (1:8) will do anything to it.

My question being........ Does the prep process remove any of the gloss I achieved during my cut and polish steps? I used 3D HD products and got great results, but am wondering if the N-914 mix (1:8) will do anything to it.