Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Review and Extreme Testing: Opti-Coat 2.0 and CQuartz

- Thread starter CEE DOG

- Start date

Avi@CarPro

New member

- Mar 24, 2011

- 544

- 0

Hi Sohail

as i answered you in the PM, we had some troubles with the cquartz caps lately, we found out it did not seal completly the bottle, and air entered the bottle causing the reaction you saw.

as i told you all cquartz is sensitive to humidity and air pressure changes.

we now solved this problem with new sealing rings inside the cap.

pls contact AG and they will compensate you for this trouble. same thing with anyone who got this problem as well.

sorry again for this trouble. i take fully responsibility for this.

as i answered you in the PM, we had some troubles with the cquartz caps lately, we found out it did not seal completly the bottle, and air entered the bottle causing the reaction you saw.

as i told you all cquartz is sensitive to humidity and air pressure changes.

we now solved this problem with new sealing rings inside the cap.

pls contact AG and they will compensate you for this trouble. same thing with anyone who got this problem as well.

sorry again for this trouble. i take fully responsibility for this.

Hi Sohail

as i answered you in the PM, we had some troubles with the cquartz caps lately, we found out it did not seal completly the bottle, and air entered the bottle causing the reaction you saw.

as i told you all cquartz is sensitive to humidity and air pressure changes.

we now solved this problem with new sealing rings inside the cap.

pls contact AG and they will compensate you for this trouble. same thing with anyone who got this problem as well.

sorry again for this trouble. i take fully responsibility for this.

Great customer service. I was on the fence but I will be ordering soon. One quick question. Can the towels used to removed the product be washed and used again or do you need to toss them?

TS656577

New member

- Nov 23, 2008

- 754

- 0

Corey has graciously allowed me to post this.

Hey everyone. So I’ve had this idea for a while and finally got around to doing the test. There was one thread that sparked this idea (http://www.autogeekonline.net/forum/how-articles/34259-understanding-headlamp-repair.html). While reading this thread, it seems that two methods are used for sealing headlights. I’ve been doing CQuartz on corrected headlights. However, CQuartz and Opti-coat are essentially adding a layer of clear coat to the paint, OC more permanent than CQ. With that being said, I began to wonder if the possibility existed of using CQ and/or OC as a clear coat of sorts on sanded panels/headlights.

I used this same test panel for another test I did using Meguiar’s MF kit, hence the extra squares. The test used the following products (and also used via the manufacturers directions):

Optimum Opti-coat 2.0

CQuartz by CarPro

CarPro Eraser

Meguiar’s 3” sanding disks – 800 grit

3M wet/dry sanding paper – 1000 grit

Meguiar’s 3” sanding disks – 1500 grit

3M wet/dry sanding paper – 2000 grit

3M wet/dry sanding paper – 3000 grit

Meguiar’s 3” sanding disks – 1500 grit

The 800 grit was not used. I have a mixture of paper/sanding disks depending on whether I’m using it on paint or sanding disks. I generally use an air polisher for headlights, hence the disks. Anyway, continuing on!

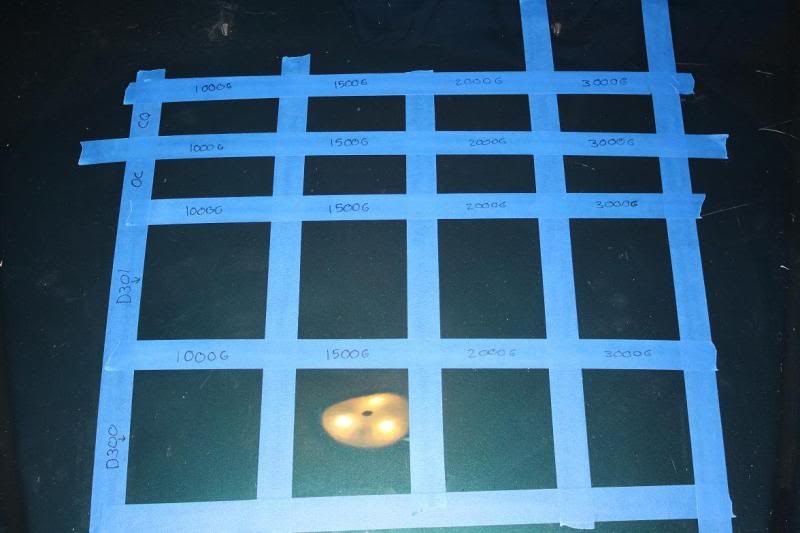

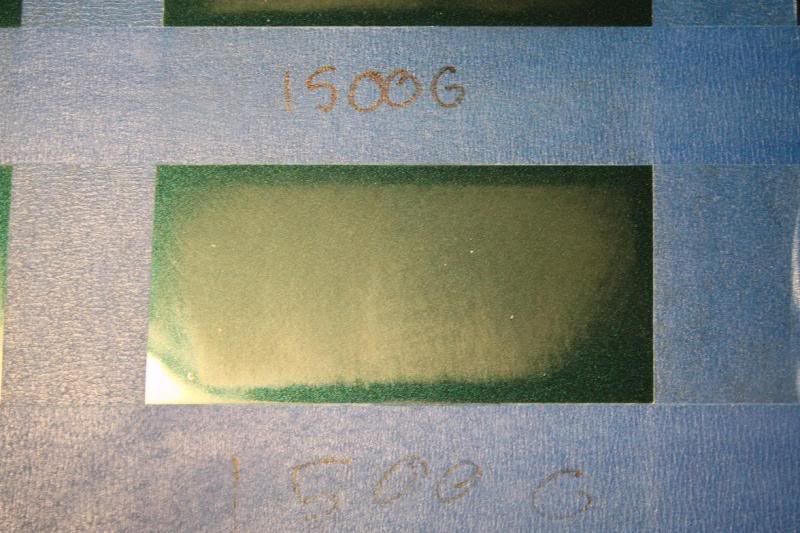

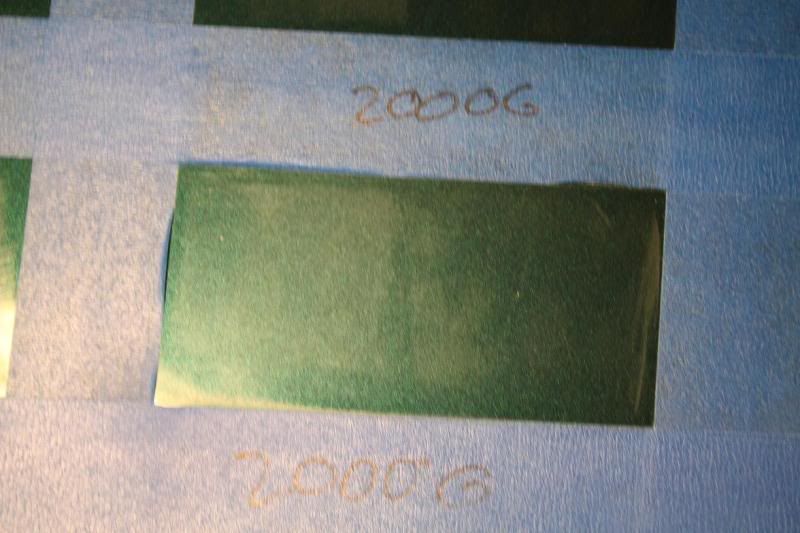

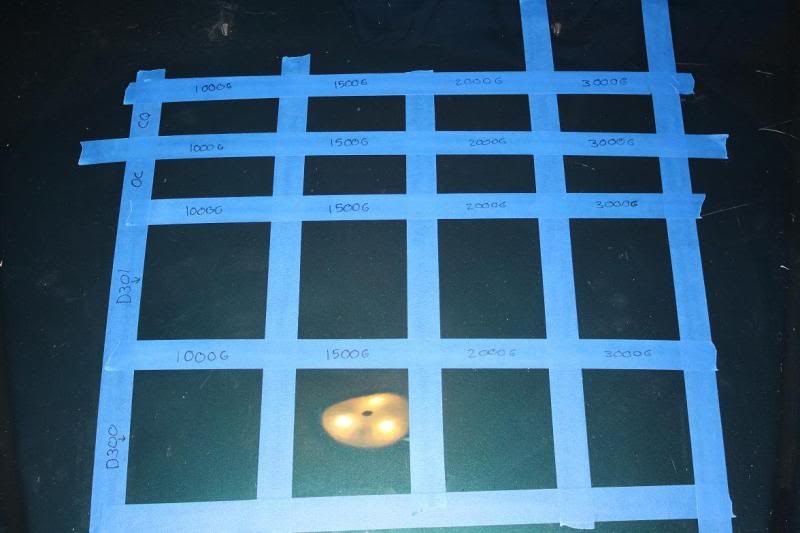

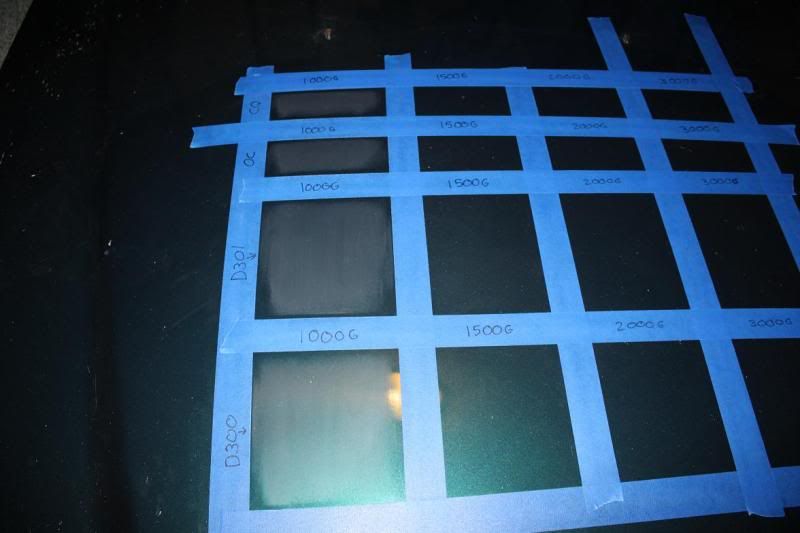

I began by taping off the test panel in sections. As seen below, the top two sections were used for the OC/CQ applications and the lower 2 were used for the other test. I then sanded each section with the corresponding sandpaper:

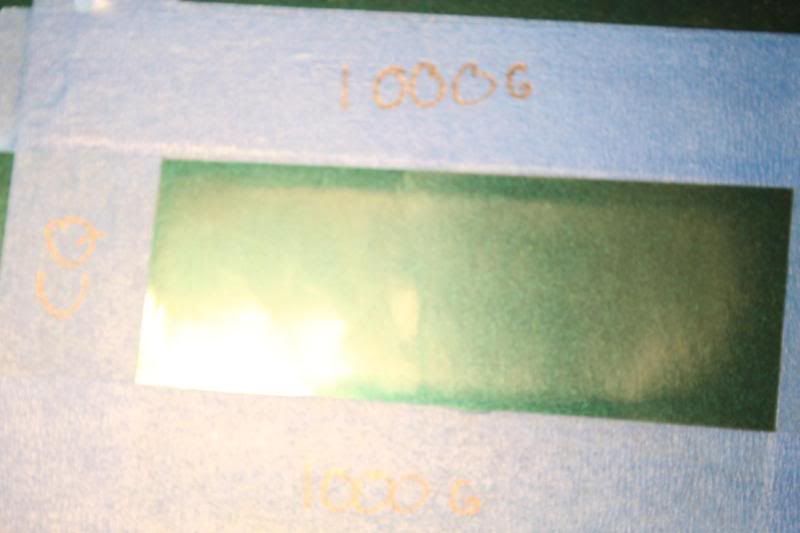

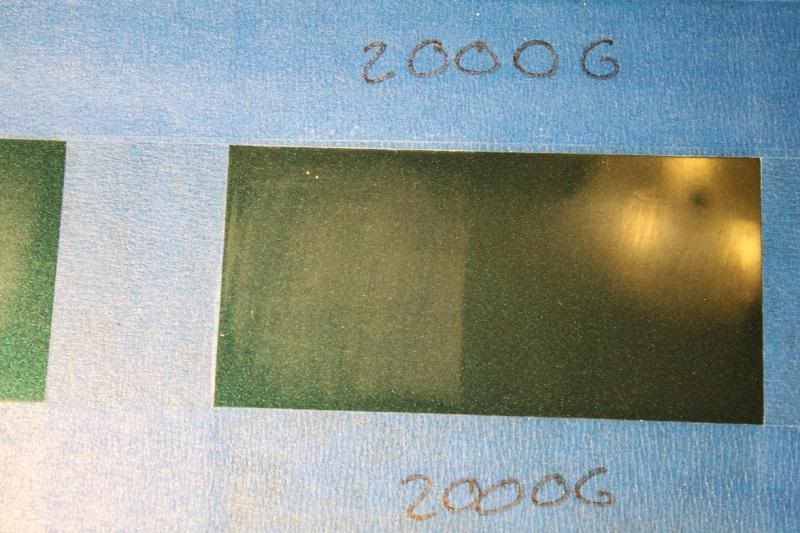

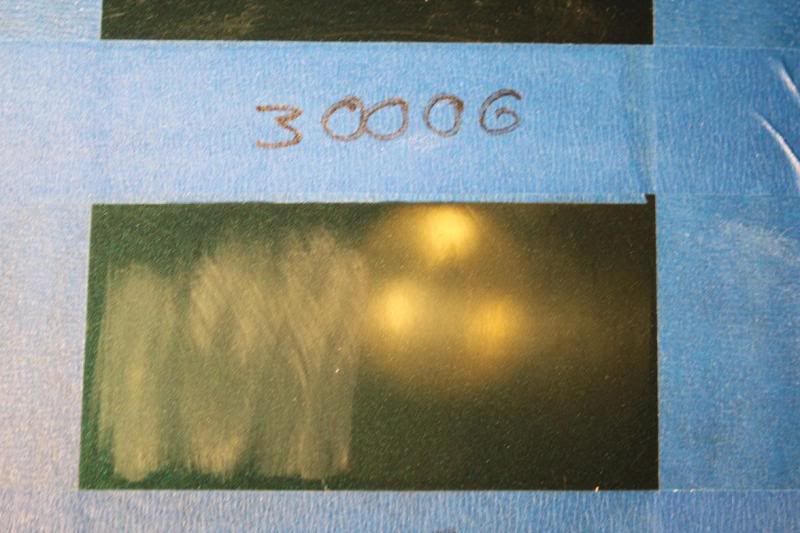

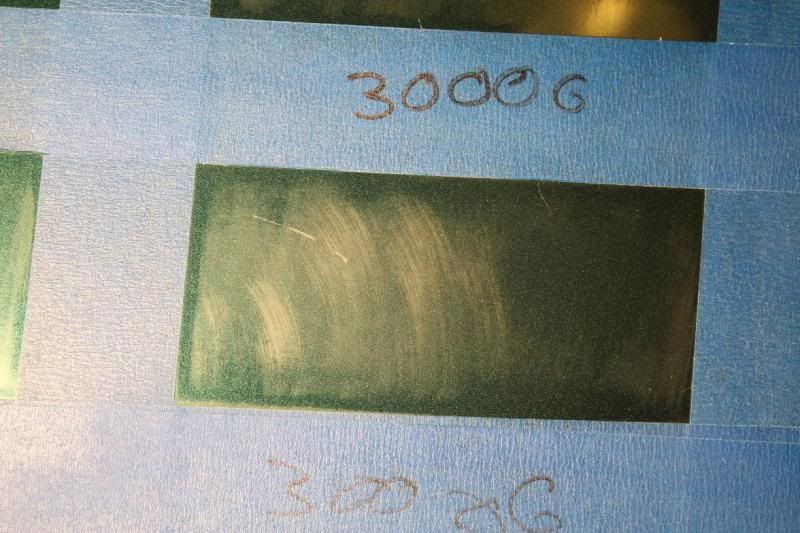

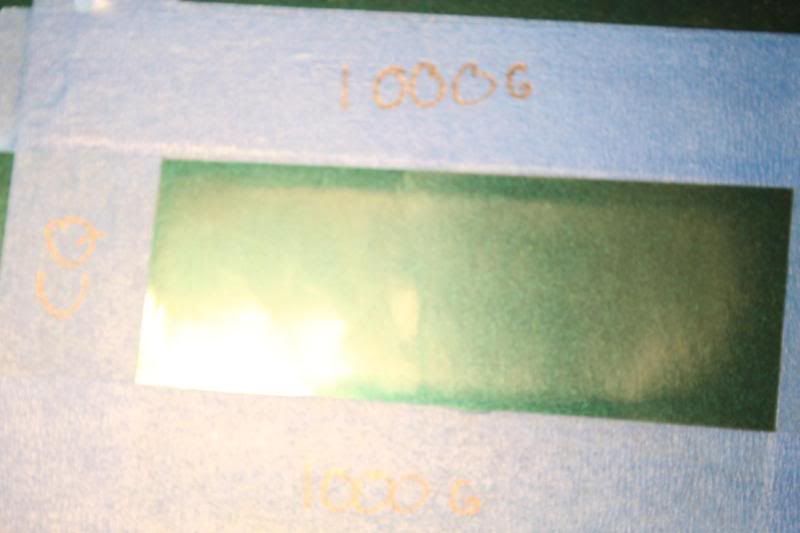

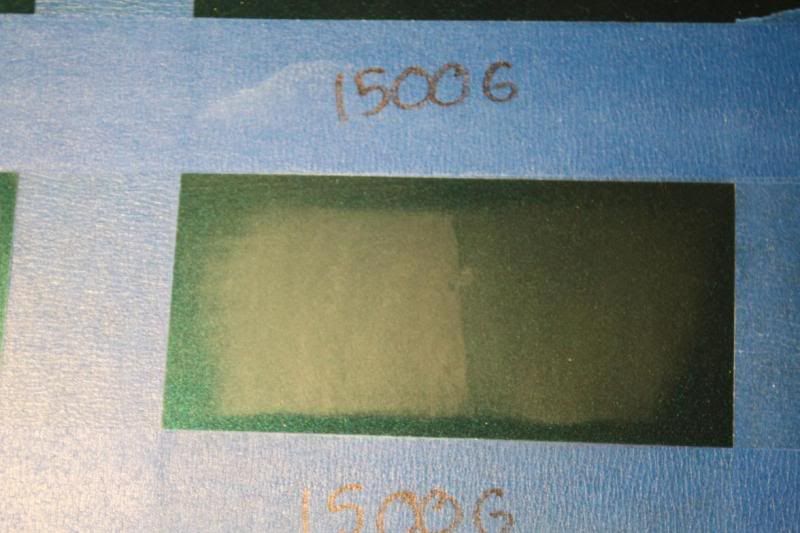

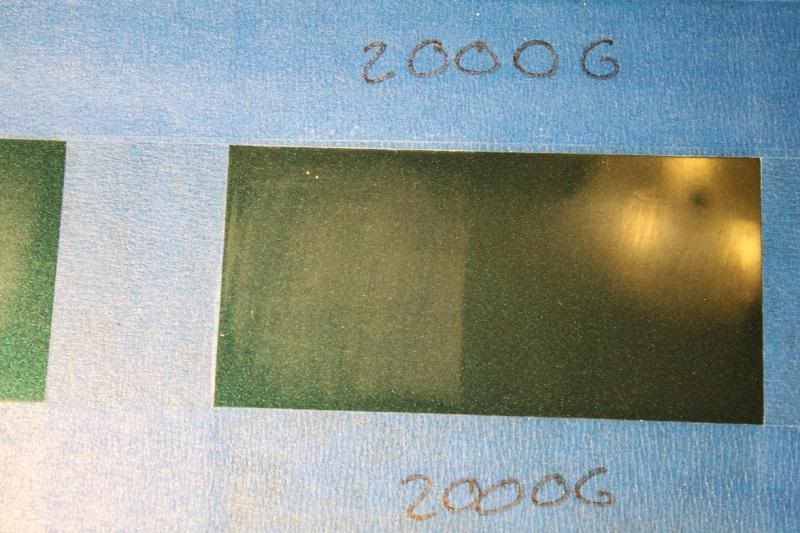

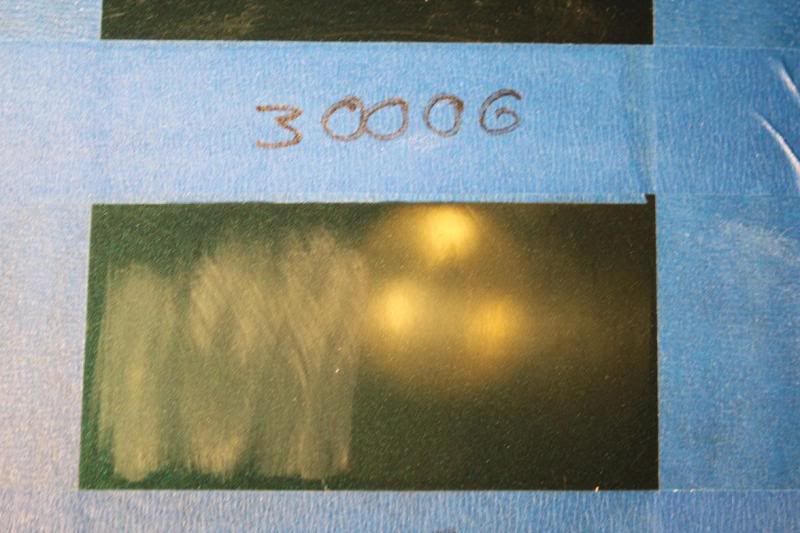

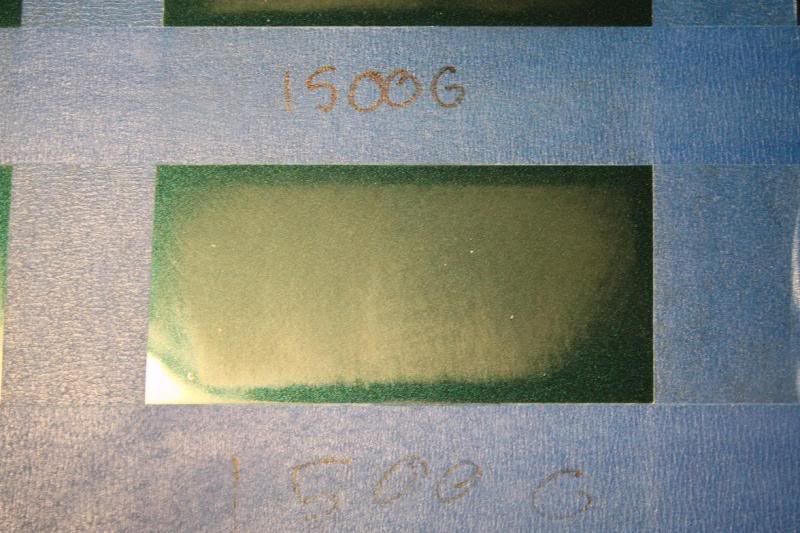

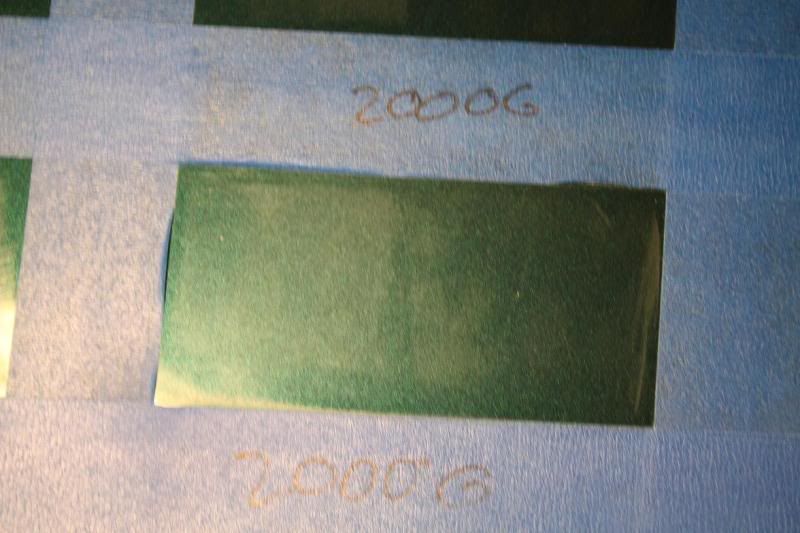

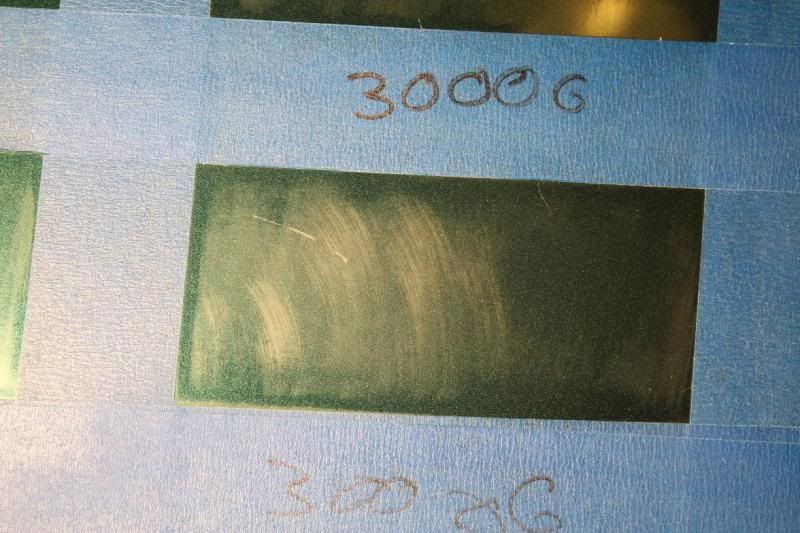

The next step was to wipe down the panel with CarPro Eraser (sorry, I apologize for no picture of the eraser). I began by first applying the CQ to the top row on the test panel. I did a 50/50 to help see the difference more easily. I apologize if there is a picture out of focus.

Now for the test spots:

1000 grit

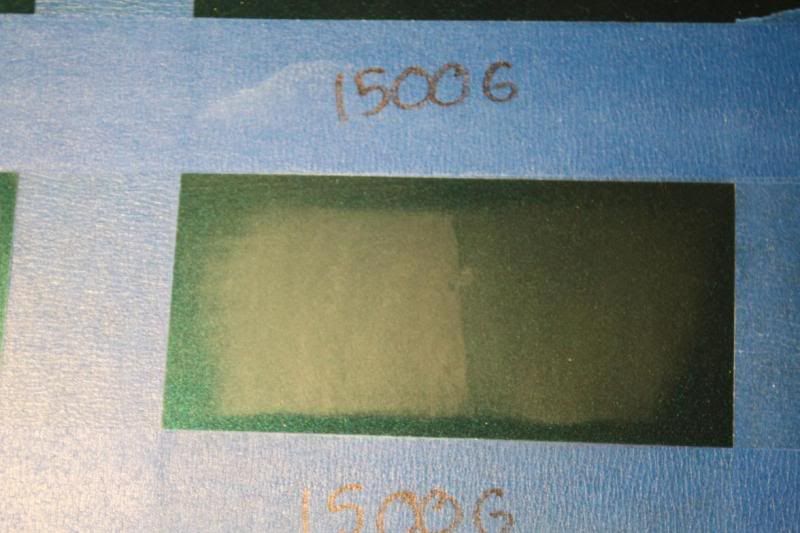

1500 grit

2000 grit

3000 grit

The next step was to apply the OC. I used OC 2.0 here (generic picture of Opti-coat from the Optimum forums)

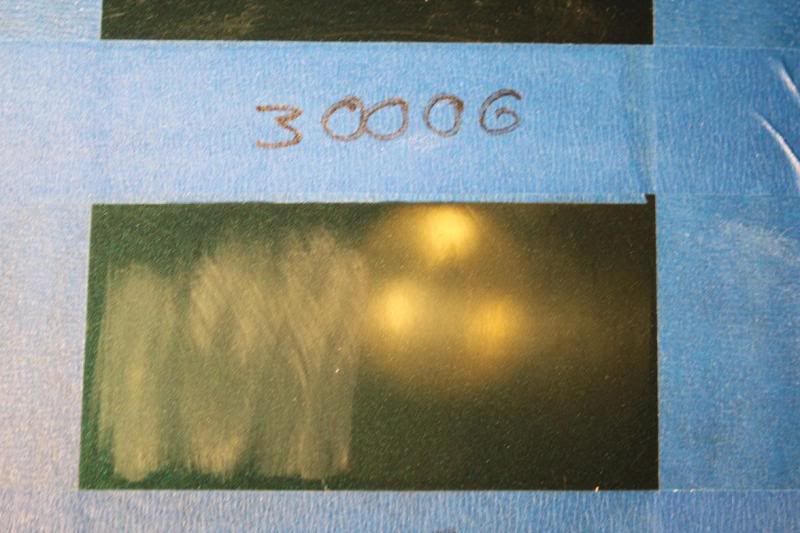

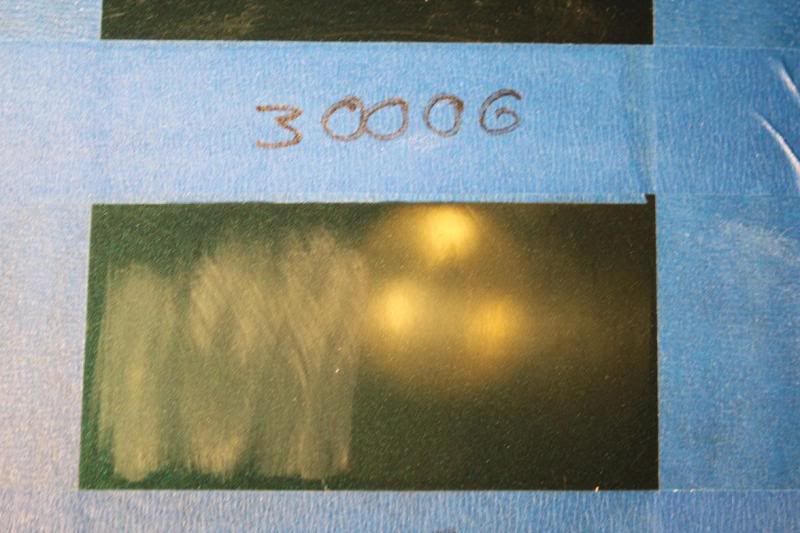

Now for the test spots:

1000 grit

1500 grit

2000 grit

3000 grit

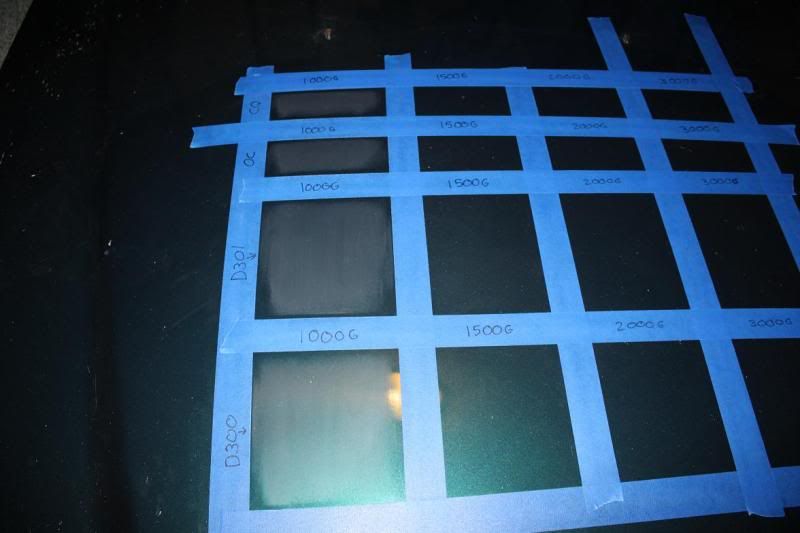

Below I have attached a better picture of the panel from above. This shows the test spots better.

All in all, I thought that Opti-coat would do a better job of filling in scratches simply because it was a more permanent coating (similar to actual clear coat). However, the last picture shows that the CQ did a better job of hiding the scratches. With that being said, I wouldn’t recommend either product for filling in scratches, even on a headlight.

If you have any questions/comments/suggestions for improvements/or something else you want to see, please feel free. All C&C is greatly welcome! And I thanks to Corey for looking over this and allowing me to put it in his fantastic review thread.

Hey everyone. So I’ve had this idea for a while and finally got around to doing the test. There was one thread that sparked this idea (http://www.autogeekonline.net/forum/how-articles/34259-understanding-headlamp-repair.html). While reading this thread, it seems that two methods are used for sealing headlights. I’ve been doing CQuartz on corrected headlights. However, CQuartz and Opti-coat are essentially adding a layer of clear coat to the paint, OC more permanent than CQ. With that being said, I began to wonder if the possibility existed of using CQ and/or OC as a clear coat of sorts on sanded panels/headlights.

I used this same test panel for another test I did using Meguiar’s MF kit, hence the extra squares. The test used the following products (and also used via the manufacturers directions):

Optimum Opti-coat 2.0

CQuartz by CarPro

CarPro Eraser

Meguiar’s 3” sanding disks – 800 grit

3M wet/dry sanding paper – 1000 grit

Meguiar’s 3” sanding disks – 1500 grit

3M wet/dry sanding paper – 2000 grit

3M wet/dry sanding paper – 3000 grit

Meguiar’s 3” sanding disks – 1500 grit

The 800 grit was not used. I have a mixture of paper/sanding disks depending on whether I’m using it on paint or sanding disks. I generally use an air polisher for headlights, hence the disks. Anyway, continuing on!

I began by taping off the test panel in sections. As seen below, the top two sections were used for the OC/CQ applications and the lower 2 were used for the other test. I then sanded each section with the corresponding sandpaper:

The next step was to wipe down the panel with CarPro Eraser (sorry, I apologize for no picture of the eraser). I began by first applying the CQ to the top row on the test panel. I did a 50/50 to help see the difference more easily. I apologize if there is a picture out of focus.

Now for the test spots:

1000 grit

1500 grit

2000 grit

3000 grit

The next step was to apply the OC. I used OC 2.0 here (generic picture of Opti-coat from the Optimum forums)

Now for the test spots:

1000 grit

1500 grit

2000 grit

3000 grit

Below I have attached a better picture of the panel from above. This shows the test spots better.

All in all, I thought that Opti-coat would do a better job of filling in scratches simply because it was a more permanent coating (similar to actual clear coat). However, the last picture shows that the CQ did a better job of hiding the scratches. With that being said, I wouldn’t recommend either product for filling in scratches, even on a headlight.

If you have any questions/comments/suggestions for improvements/or something else you want to see, please feel free. All C&C is greatly welcome! And I thanks to Corey for looking over this and allowing me to put it in his fantastic review thread.

Matt

Active member

- Aug 25, 2008

- 1,276

- 0

Nice test Trent, although I do believe the original thread where opticoat was used for headlight refinishing was where the opticoat was used on a polished lense and the reason for leaving it sanded on the painted headlight was for the clearcoat paint to adhere better to the lense, as the sanding provided mechanical "bite" rather than chemical adhesion.

I wouldnt expect the opticoat to fill in scratches like clearcoat however, as it is very different to clearcoat even though it adds an additional permanent layer of protection to the paint.

Great write up, clear and concise- to the point.

- Matt

I wouldnt expect the opticoat to fill in scratches like clearcoat however, as it is very different to clearcoat even though it adds an additional permanent layer of protection to the paint.

Great write up, clear and concise- to the point.

- Matt

richy

New member

- Mar 27, 2007

- 5,158

- 0

Those words are hardly ever spoke in today's day and age...God Bless you Avi. That's great customer service there!!Hi Sohail

as i answered you in the PM, we had some troubles with the cquartz caps lately, we found out it did not seal completly the bottle, and air entered the bottle causing the reaction you saw.

as i told you all cquartz is sensitive to humidity and air pressure changes.

we now solved this problem with new sealing rings inside the cap.

pls contact AG and they will compensate you for this trouble. same thing with anyone who got this problem as well.

sorry again for this trouble. i take fully responsibility for this.

Ya, toss them....directly into a pail of a strong APC solution. Good as new.Great customer service. I was on the fence but I will be ordering soon. One quick question. Can the towels used to removed the product be washed and used again or do you need to toss them?

TS656577

New member

- Nov 23, 2008

- 754

- 0

Nice test Trent, although I do believe the original thread where opticoat was used for headlight refinishing was where the opticoat was used on a polished lense and the reason for leaving it sanded on the painted headlight was for the clearcoat paint to adhere better to the lense, as the sanding provided mechanical "bite" rather than chemical adhesion.

I wouldnt expect the opticoat to fill in scratches like clearcoat however, as it is very different to clearcoat even though it adds an additional permanent layer of protection to the paint.

Great write up, clear and concise- to the point.

- Matt

Thanks for the comment! And you are correct with saying the sanded headlights were left as such for clear to adhere and that OC/CQ are applied to corrected surfaces. And now I know not to use it unless the surface is corrected!

Avi@CarPro

New member

- Mar 24, 2011

- 544

- 0

[/QUOTE] All in all, I thought that Opti-coat would do a better job of filling in scratches simply because it was a more permanent coating (similar to actual clear coat). However, the last picture shows that the CQ did a better job of hiding the scratches. With that being said, I wouldn’t recommend either product for filling in scratches, even on a headlight.

If you have any questions/comments/suggestions for improvements/or something else you want to see, please feel free. All C&C is greatly welcome! And I thanks to Corey for looking over this and allowing me to put it in his fantastic review thread.[/QUOTE]

Please define the word "Permanent" !

what is permanent?? if its something you cant remove no matter what ok... so this means permanent

but if the definition of "permanent " means : cant remove by any chemicals and only mechanic abrasion.. so Cquartz is defiantly permanent coat!

If you have any questions/comments/suggestions for improvements/or something else you want to see, please feel free. All C&C is greatly welcome! And I thanks to Corey for looking over this and allowing me to put it in his fantastic review thread.[/QUOTE]

Please define the word "Permanent" !

what is permanent?? if its something you cant remove no matter what ok... so this means permanent

but if the definition of "permanent " means : cant remove by any chemicals and only mechanic abrasion.. so Cquartz is defiantly permanent coat!

LegacyGT

New member

- Aug 13, 2010

- 2,090

- 0

Trent - very interesting and unique test, thanks for taking the time to put this all together.

When looking at the pictures posted I wanted to confirm an observation since sometimes human eyes see thing IRL better than in photos.

In this photo the CQ fills in the 3000Grit sanding quite nicely (which was surprising) but it looks like the gloss is not restored and that the paint is still hazy underneath the CQ coating. When looking at this IRL is this the case?

Where I am going with this is that the popular Spar/Mineral spirits combo does a very good job at creating a transparent & glossy surface so the light travels directly through and is not scattered. From what I believe I am observing in your pictures is that when using either CQ or OC on headlights they should be finely polished before applying a coating, unlike using Spar or 3K Clear that works best with a roughed surface to bond to.

When looking at the pictures posted I wanted to confirm an observation since sometimes human eyes see thing IRL better than in photos.

In this photo the CQ fills in the 3000Grit sanding quite nicely (which was surprising) but it looks like the gloss is not restored and that the paint is still hazy underneath the CQ coating. When looking at this IRL is this the case?

Where I am going with this is that the popular Spar/Mineral spirits combo does a very good job at creating a transparent & glossy surface so the light travels directly through and is not scattered. From what I believe I am observing in your pictures is that when using either CQ or OC on headlights they should be finely polished before applying a coating, unlike using Spar or 3K Clear that works best with a roughed surface to bond to.

TS656577

New member

- Nov 23, 2008

- 754

- 0

Please define the word "Permanent" !

what is permanent?? if its something you cant remove no matter what ok... so this means permanent

but if the definition of "permanent " means : cant remove by any chemicals and only mechanic abrasion.. so Cquartz is defiantly permanent coat!

Avi, I was going by the descriptions I've read from both Optimum and you guys. If I remember correctly, Opti-coat is advertised as lasting for the life of the car. On the other hand, CQ is said to last for roughly 3 years (which is no slouch for protection either!). I apologized if I wasn't clear, but hopefully this clears it up.

Trent - very interesting and unique test, thanks for taking the time to put this all together.

In this photo the CQ fills in the 3000Grit sanding quite nicely (which was surprising) but it looks like the gloss is not restored and that the paint is still hazy underneath the CQ coating. When looking at this IRL is this the case?

Where I am going with this is that the popular Spar/Mineral spirits combo does a very good job at creating a transparent & glossy surface so the light travels directly through and is not scattered. From what I believe I am observing in your pictures is that when using either CQ or OC on headlights they should be finely polished before applying a coating, unlike using Spar or 3K Clear that works best with a roughed surface to bond to.

You're correct. In general the CQ filled the scratches MUCH better than OC. However, the haze you are referring to is actually still scratches. If filled them in but during close inspection, you can see that the scratches are still there , just slightly glossier than the non-coated counterpart. Also, CQ and OC are meant to be applied to polished surfaces, including headlights. I'm sure that OC and CQ would bond very will with a sanded surface, but they were designed for polished surfaces.

Matt

Active member

- Aug 25, 2008

- 1,276

- 0

Opti-coat is advertised as lasting for the life of the car. On the other hand, CQ is said to last for roughly 3 years

:iagree:

3 years is an amazing feat, and given you can later the product I'm sure you could get even longer durability, but I wouldn't call 3 years permanent.

Permanent is something that will be there a lot longer than 3 years.

So I have read thru this whole thread and see that Cquartz and Opticoat act in the same way as sheeting properties and in his experience both are about the same. I was wondering what is the principle difference in the two technologies nanocoat vs resin? Also is there a feature that one does that the other would not? Ex. would opticoat sheeting properties stop after a while even tho it is technically on the coating for life?

Cee Dog... Do you still prefer one over the other? If so why?

Cee Dog... Do you still prefer one over the other? If so why?

CEE DOG

New member

- Jul 12, 2009

- 7,358

- 0

- Thread starter

- #155

Wow! That was an amazingly thorough test. Thank you, you did an outstanding job!

Thank you!!

So I have read thru this whole thread and see that Cquartz and Opticoat act in the same way as sheeting properties and in his experience both are about the same. I was wondering what is the principle difference in the two technologies nanocoat vs resin? Also is there a feature that one does that the other would not? Ex. would opticoat sheeting properties stop after a while even tho it is technically on the coating for life?

Cee Dog... Do you still prefer one over the other? If so why?

The Opticoat will not stop beading for the life of its durability.

Well, the two technologies are very different. I could go into a bunch of things I've noted since using them both but I'll keep it to what I consider to be the important factors for people.

1.-The first few times you use these products the CQuartz is easier to apply and you have no chance of high spots.

2.-After you have mastered the application of both products (If you are going to use them regularly) Opticoat is physically less taxing to apply to most cars. (unless they have a ton of intracicies)

3.-For daily drivers I prefer Opticoat because I don't have to buff it off. And most importantly it is a sacrificial coating.

4.-For Show cars or Garage queens I prefer CQuartz because I believe it produces greater clarity compared to OC. They both really look great and it's near impossible to tell the difference but the CQuartz seems to be more leveled in my testing so even though I can't see the difference in clarity it stands to reason more level surface = greater clarity.

5.-CQuartz fully hardens faster than OptiCoat.

So,

A.- If someone is detailing as a profession then my recomendation would hinge on what kind of clients and cars they have as well as the environment. I would say if they will be adding a coating service to their menu they should try 3 applications of each and decide which product works best for them.

B.- If someone was going to just coat one car I would recomend Cquartz because it doesn't have the same learning curve.

CEE DOG

New member

- Jul 12, 2009

- 7,358

- 0

- Thread starter

- #156

So I have read thru this whole thread and see that Cquartz and Opticoat act in the same way as sheeting properties and in his experience both are about the same. I was wondering what is the principle difference in the two technologies nanocoat vs resin? Also is there a feature that one does that the other would not? Ex. would opticoat sheeting properties stop after a while even tho it is technically on the coating for life?

Cee Dog... Do you still prefer one over the other? If so why?

Thank you!!rops:

The Opticoat will not stop beading for the life of its durability.

Well, the two technologies are very different. I could go into a bunch of things I've noted since using them both but I'll keep it to what I consider to be the important factors for people.

1.-The first few times you use these products the CQuartz is easier to apply and you have no chance of high spots.

2.-After you have mastered the application of both products (If you are going to use them regularly) Opticoat is physically less taxing to apply to most cars. (unless they have a ton of intracicies)

3.-For daily drivers I prefer Opticoat because I don't have to buff it off. And most importantly it is a sacrificial coating.

4.-For Show cars or Garage queens I prefer CQuartz because I believe it produces greater clarity compared to OC. They both really look great and it's near impossible to tell the difference but the CQuartz seems to be more leveled in my testing so even though I can't see the difference in clarity it stands to reason more level surface = greater clarity.

5.-CQuartz fully hardens faster than OptiCoat.

So,

A.- If someone is detailing as a profession then my recomendation would hinge on what kind of clients and cars they have as well as the environment. I would say if they will be adding a coating service to their menu they should try 3 applications of each and decide which product works best for them.

B.- If someone was going to just coat one car I would recomend Cquartz because it doesn't have the same learning curve.

I got a pm from someone that said it was confusing what I wrote in this post about the beading. Let me clarify.

You asked if OC would still bead permanently. It will bead for the life of the coating as will the CQuartz. As long as those coatings are on there they will bead. When the coatings have been worn off they will no longer bead. When they are dirty beading does not show with the same hydrophbic extreme contact angle. The dirtier they are the less the beading.

If the car is clean and they don't bead as well as they used to then it means the coating has been worn down and the coating is thin or wearing where you see this. If that happens after only a few months instead of years then the product was not applied properly or the surface was not cleaned properly.

I got a pm from someone that said it was confusing what I wrote in this post about the beading. Let me clarify.

You asked if OC would still bead permanently. It will bead for the life of the coating as will the CQuartz. As long as those coatings are on there they will bead. When the coatings have been worn off they will no longer bead. When they are dirty beading does not show with the same hydrophbic extreme contact angle. The dirtier they are the less the beading.

If the car is clean and they don't bead as well as they used to then it means the coating has been worn down and the coating is thin or wearing where you see this. If that happens after only a few months instead of years then the product was not applied properly or the surface was not cleaned properly.

Thanks Corey,

Also this learning curve is the same with 2.0? Cquartz still easier than Opticoat 2.0?

S7ICKlVlAN

New member

- Mar 12, 2012

- 28

- 0

Amazing review.....WOW! Cee Dog, good stuff bro. I'm heavily considering the OC product for future use. Thanks.

CEE DOG

New member

- Jul 12, 2009

- 7,358

- 0

- Thread starter

- #160

Thanks Corey,

Also this learning curve is the same with 2.0? Cquartz still easier than Opticoat 2.0?

My pleasure, I would say CQ is less stressful and mentally easier than OC any version. OC is easier physically than CQ as you do not have to buff it off. OC is easier Once you have spent time with both but you have to pay close attention because you can leave high spots where as you can not with CQ.

PS, my sincere apologies for not seeing your question sooner.

Amazing review.....WOW! Cee Dog, good stuff bro. I'm heavily considering the OC product for future use. Thanks.

My pleasure! Thank you!

Corey, this is a classic thread. I've looked at it numerous times as I consider OC. Nice to see one of the "good guys" who put in the time for others was recognized this weekend.

A thankful newbie!

Thank you Jim!!! That means a ton to me!