First - NICE BOAT!

blambert said:

1674805]okay found some rupes pads.

going to order 5 of the 6 inch and 3 of the 4 inch.

That will work. Buff until all pads have become wet or soggy and then stop for the day. Wash and dry the pads and they will be ready to go for the next day.

blambert said:

no luck finding the Marine 31 Captain’s One-Step Compound & Polish in Canada so. any other brand you recommend over 3M ?

Yeah - Marine 31 is only available online. My next go to product would be either the Menzerna FG500 or RUPES Zephir Gloss compound.

blambert said:

went through the links you attached lots of good info in them. wish i went through them before i ordered the porter cable kit from chemical guys. but ill just use the foam pads on my truck.

That will work.

blambert said:

wondering if these are the correct steps

start off by washing the boat.

compound with a blue rupes pad.

polish with a blue rupes pad.

and wax by hand.

That will work. If it were me I would machine apply the wax too. The machine always outperforms the human.

blambert said:

also noticed rupes has some wool pads for DA polishers.

RUPES makes great fiber pads. In context to the detailing world, these are fairly new. I have not used them to try to do what you're doing. I don't show these in my classes because I show a FULL BLOWN process that by-passes this approach.

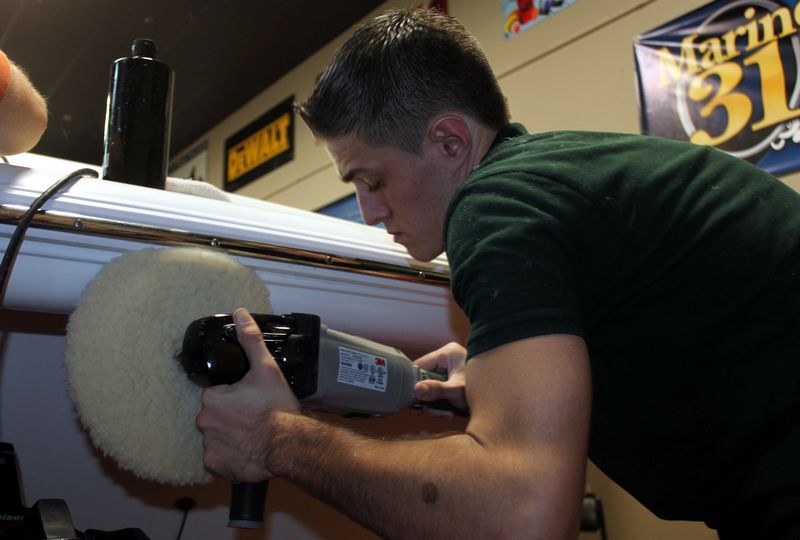

For my classes I bring in boats in HORRIBLE condition and we machine sand them and then use rotary buffers with wool pads to remove the sanding marks. After that we machine polish. The results are a "Show Car" finish on a boat. But it costs more to do this and requires more tools and products and a little training goes a long way.

Here's the deal, (gosh I type this over and over on this forum),

FIBERS ARE ABRASIVES

This means they will CUT better than FOAM. The problem is they CUT and this means after you use one, while it may have removed the defects, in you case oxidation faster, it leaves cuts called micro-marring in the paint.

Micro-marring comes from using orbital polishers.

If you were to use a fiber pad on a rotary buffer it would leave HOLOGRAMS.

Both make the paint LESS clear and glossy and also increase the surface area which then promotes or accelerates future oxidation.

The remedy is to cut first with a fiber pad - accept it might look dull and the RE-POLISH using a sharp, hard foam pad. This will undo the dulling of a fiber pad.

This is all deep stuff. I have to type out info for a WIDE SPECTRUM of people that often times hold MY information to the highest standard. If a person is not that deep into perfection, then here's the quick, fast easy way to make oxidized gel-coat shiny, not perfect but shiny.

Get a GREAT Marine One-Step Cleaner/Wax and machine apply using a rotary buffer and a traditional wool pad. This approach will remove the oxidation FAST and leave the gel-coat shiny. Then wax over this and done.

I've actually shown this in my classes for the TOP CAP of a boat because trying to do show car detailing to the COMPLICATED design of a top cap on a boat is TIME CONSUMING - especially if you want to use a CERAMIC COATING instead of wax.

There's million ways to skin this cat and most will work. Which way is best for you depends on your expectations for finish results and how much time you want to invest.

blambert said:

and in one of your links i seen you used lake country purple foam wool pads. i can also get those.

That's a fairly old article. Always look at the TIME STAMP for anything I write. I write in such a way that the info is accurate over time but products CHANGE. Those pads you saw are still around, they are called Purple Foamed Wool Pads and do they work? Sure. Are they best for what you want to do? I'd say "no". If you want to cut faster then get these RUPES pads

RUPES 3.5 Inch Coarse Wool Pad

6 inch RUPES Coarse Blue Wool Polishing Pad

A couple comments about fiber pads, (any type of fiber pad)

Unlike a foam cutting pad, which loses it's cutting ability as it becomes wet or saturated with product, a fiber pad will cut fairly consistently wet or dry. So you can buff longer with a fiber pad.

If you see any micro-marring or dulling after using a fiber pad and then wiping off the residue, assuming it's not the product it's the pad - you can re-polish using foam and remove the micro-marring or dull looking haze.

The individual fibers CUT the surface whereas a foam pad has a UNIFORM SURFACE TEXTURE - it's this uniform surface texture, (plus the fact that it's foam), that enables a foam pad to finish out NICER more CONSISTENTLY over a wider spectrum of materials, (gel-coat, plastic, paint etc.), than a fiber pad.

The above is a LOT of info to soak in, I hope it's helping more than it's hurting.