Nick Chapman

New member

- Apr 5, 2009

- 41

- 0

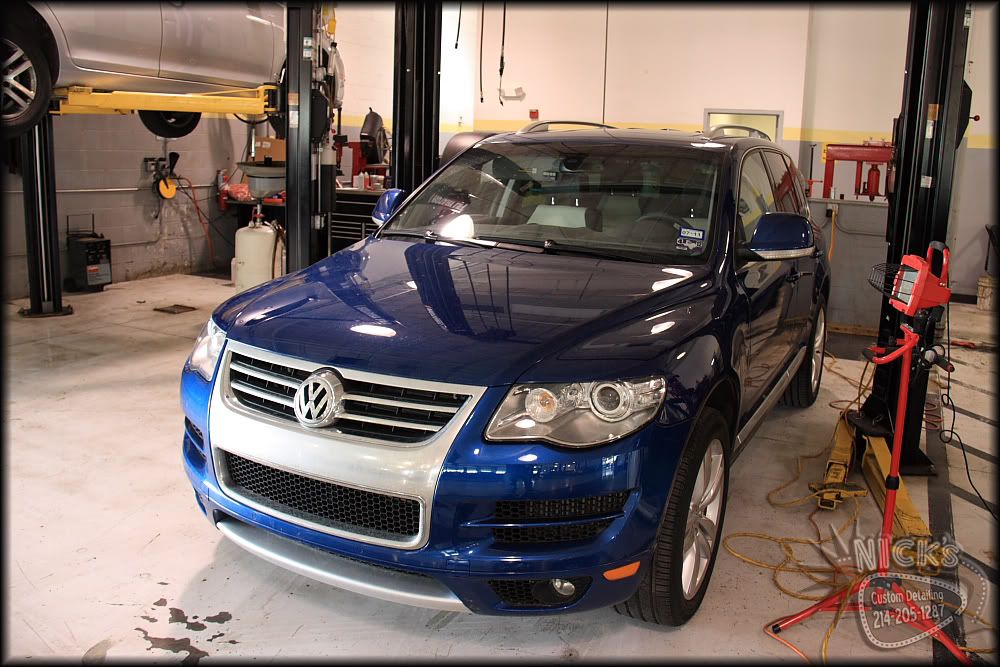

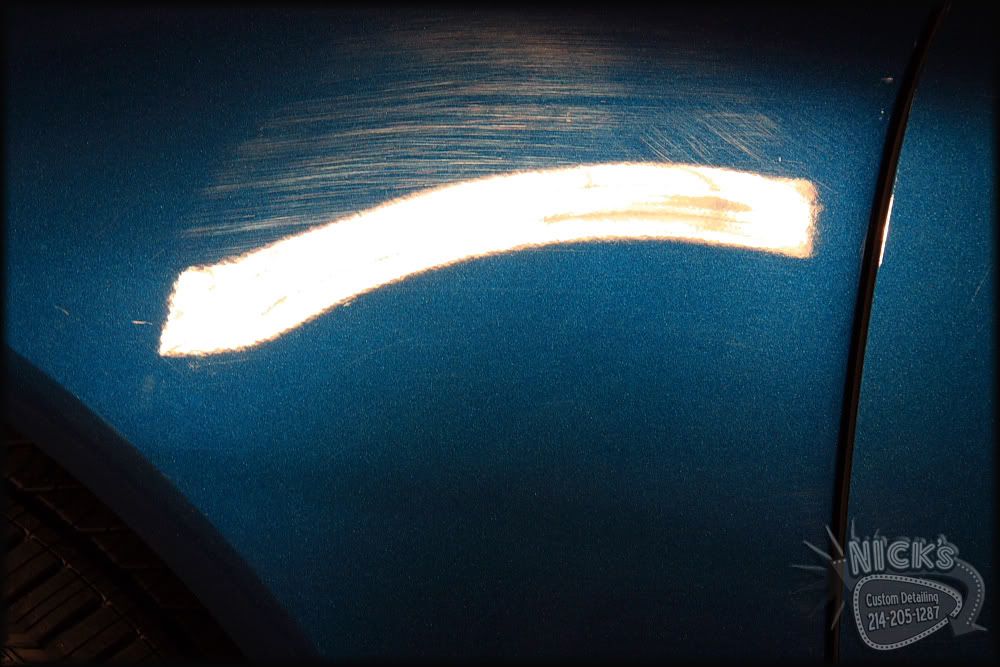

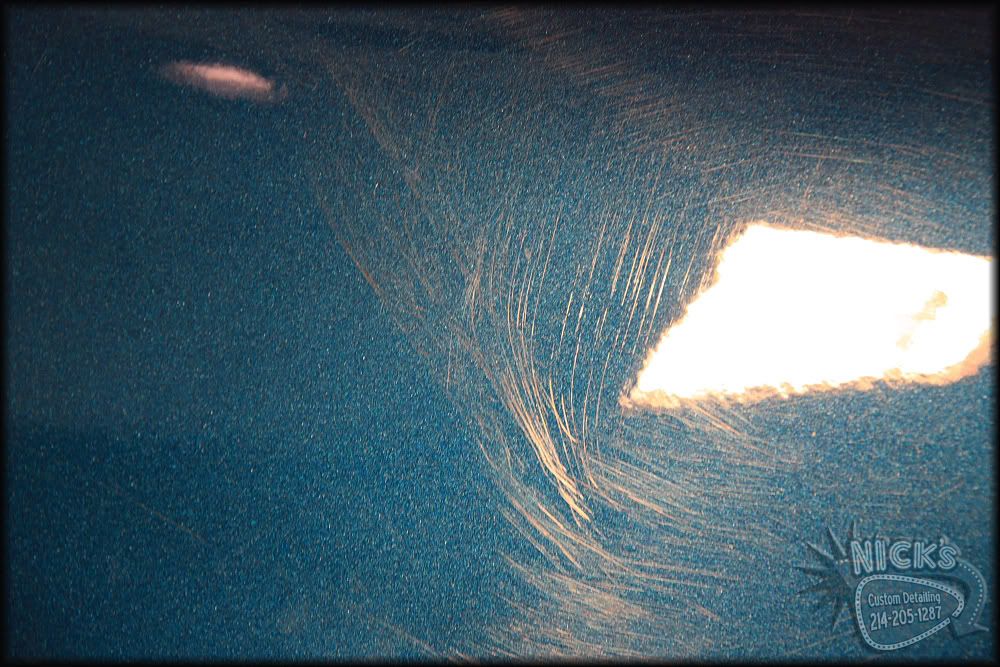

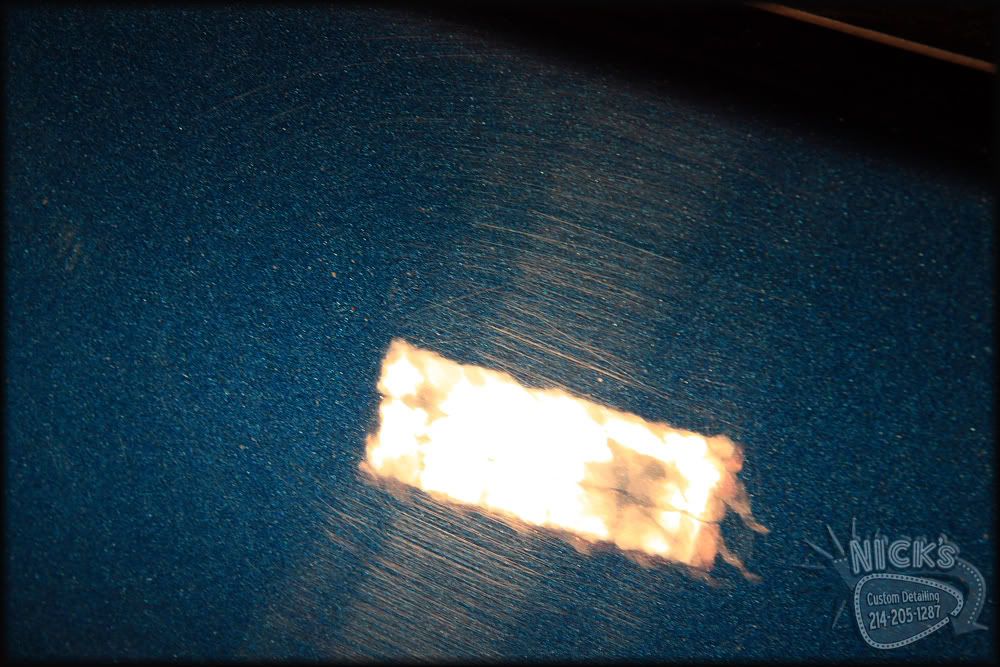

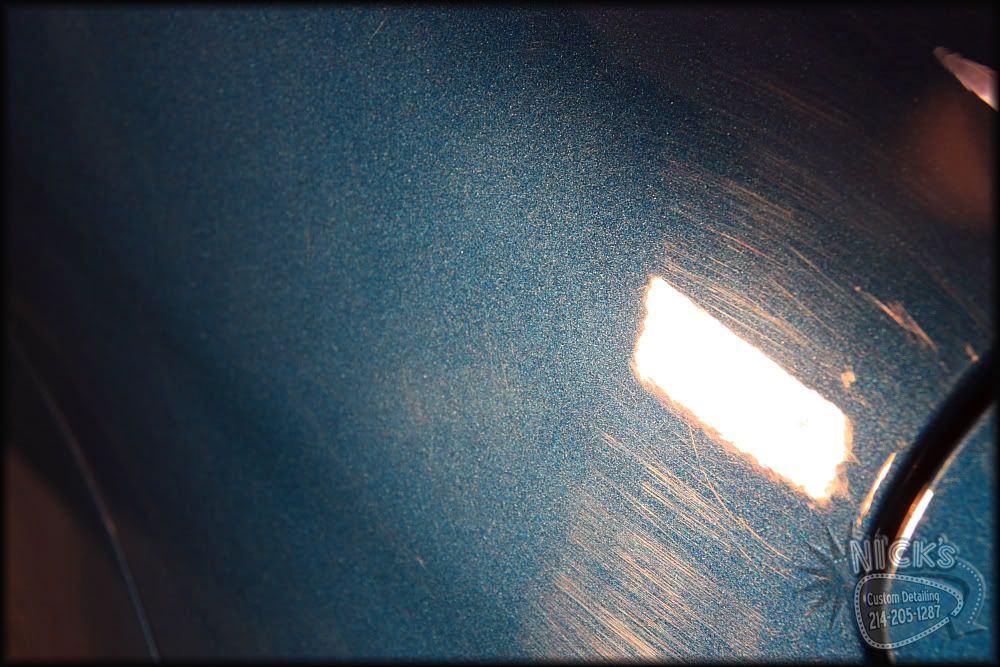

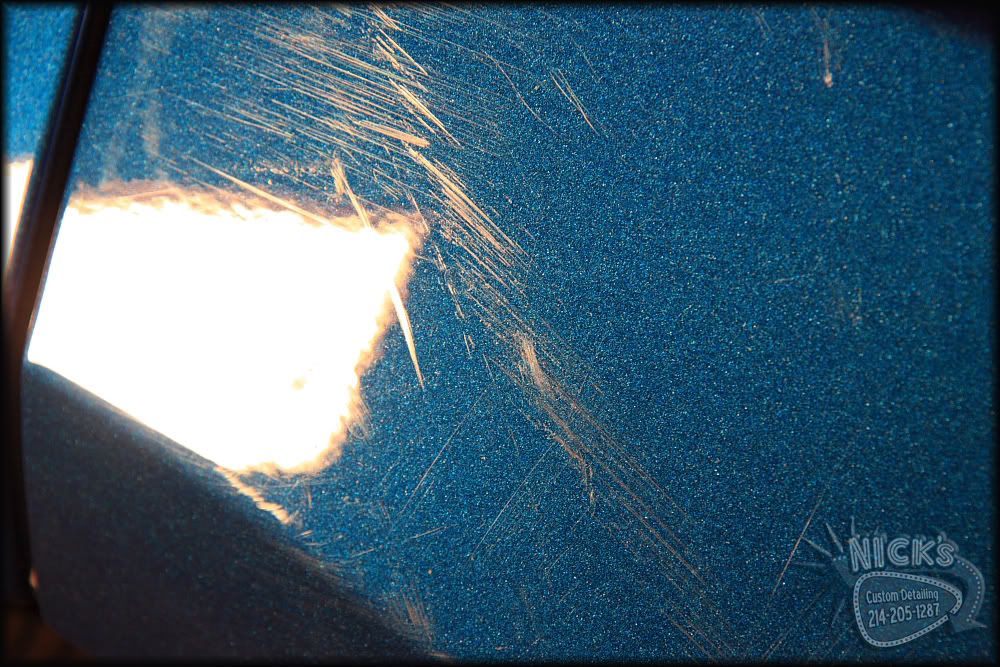

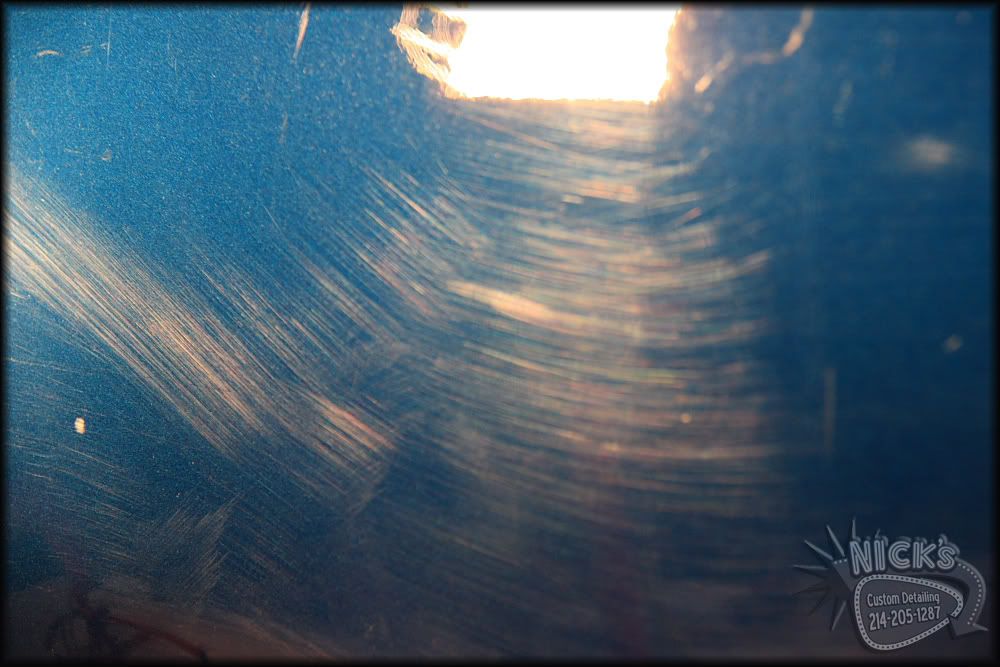

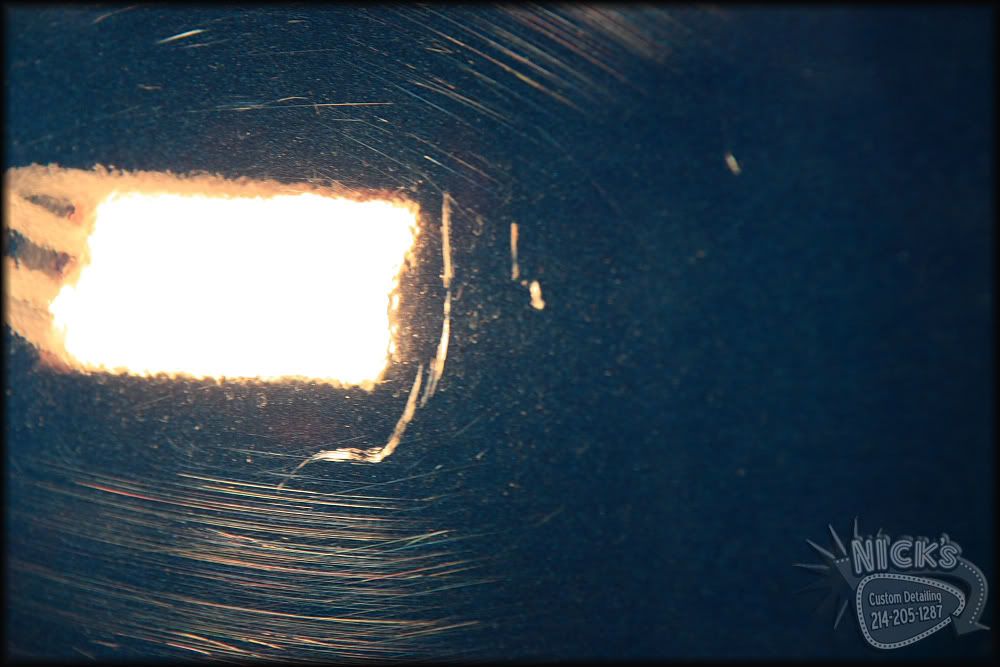

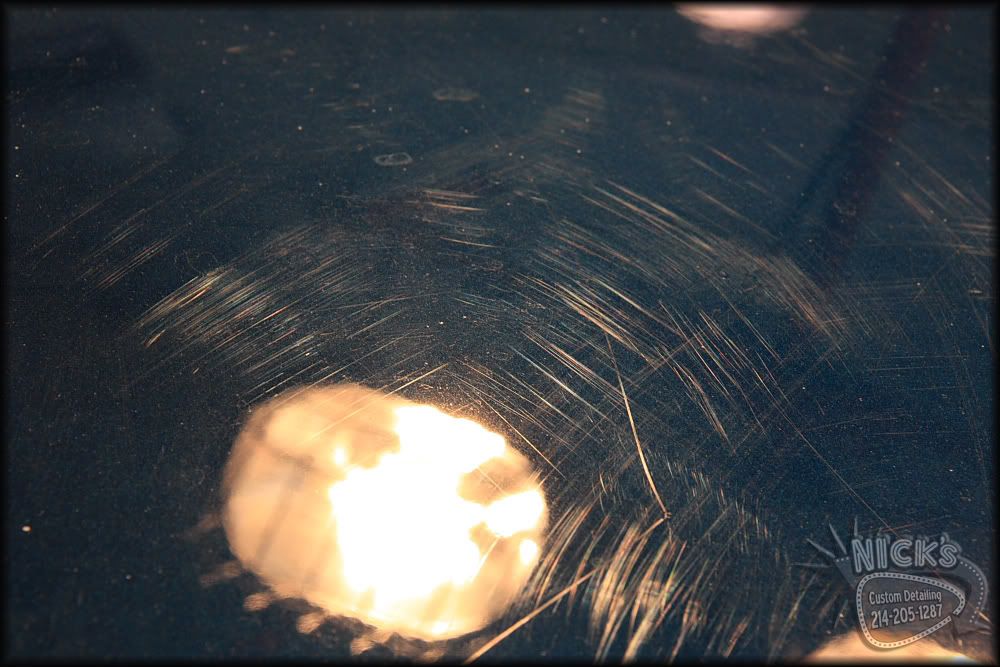

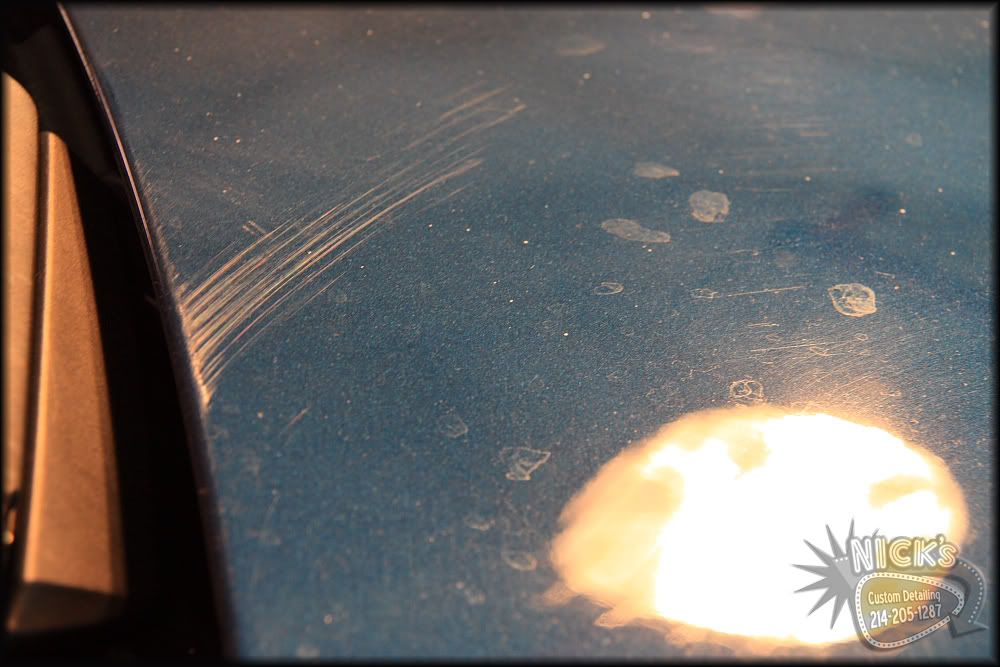

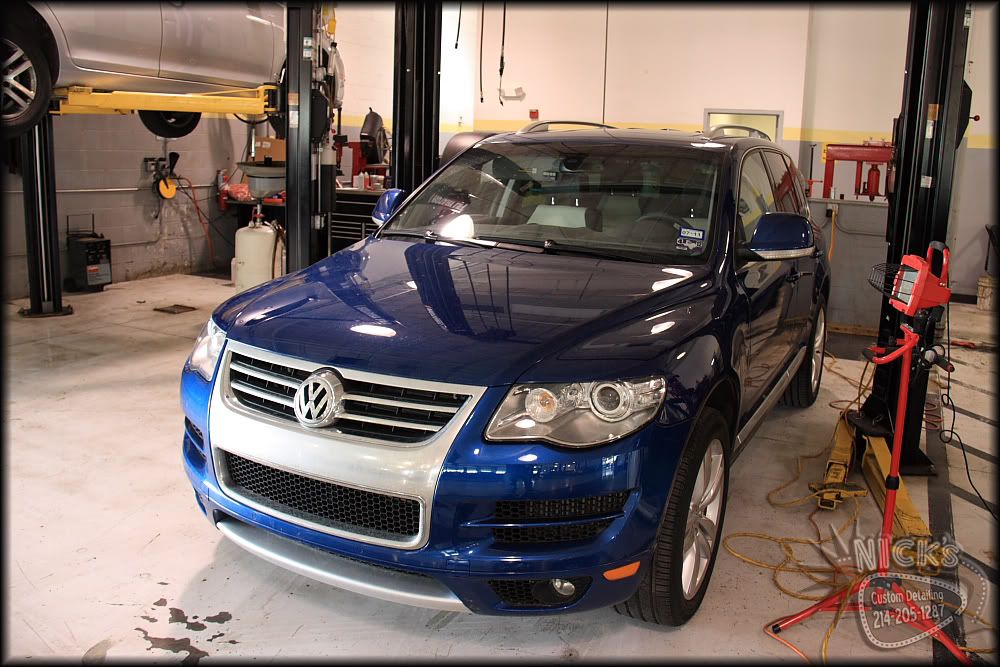

Trashed! That’s about the best description for this Touareg! Owner of this beauty actually owns a VW Dealership. He has a home here in Texas(full time home), and also a place up in Colorado, where this car has been for the past few months. He brought it back to Texas to have me go over it, because he was completely frustrated with the “Colorado Look” that it has. By now, it’s on it’s way back up to Colorado again for another year. I’m sure I’ll be visiting this car again soon.

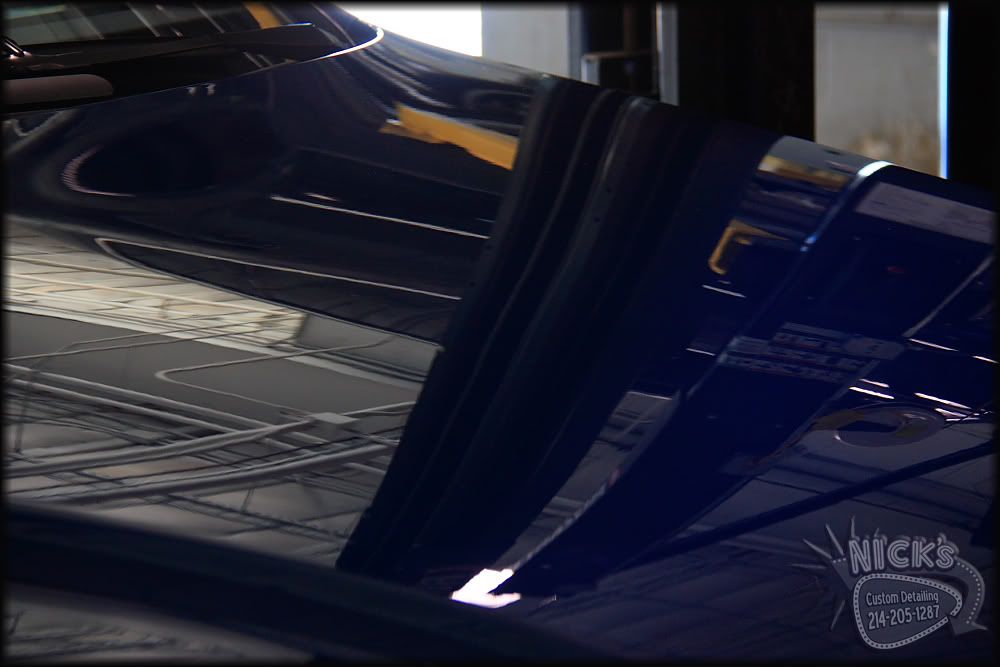

Washed with Chemical Guys Citrus Based cleaner to strip everything away. Then clayed with Meguiar’s medium cut clay. Then corrected with Meguiar’s G110v2 and a 5” Microfiber Pad and M105, then straight to wax. Had some Rejex that I’ve had for a while, never used it so I thought I’d throw it on this beater

Total time on this car was 13 hours, interior and exterior

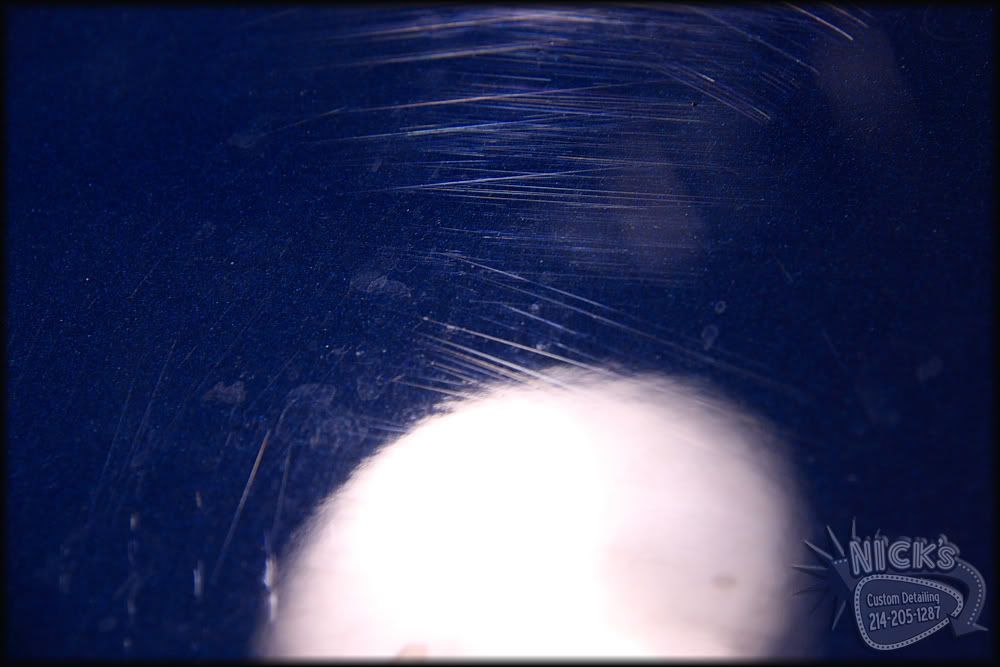

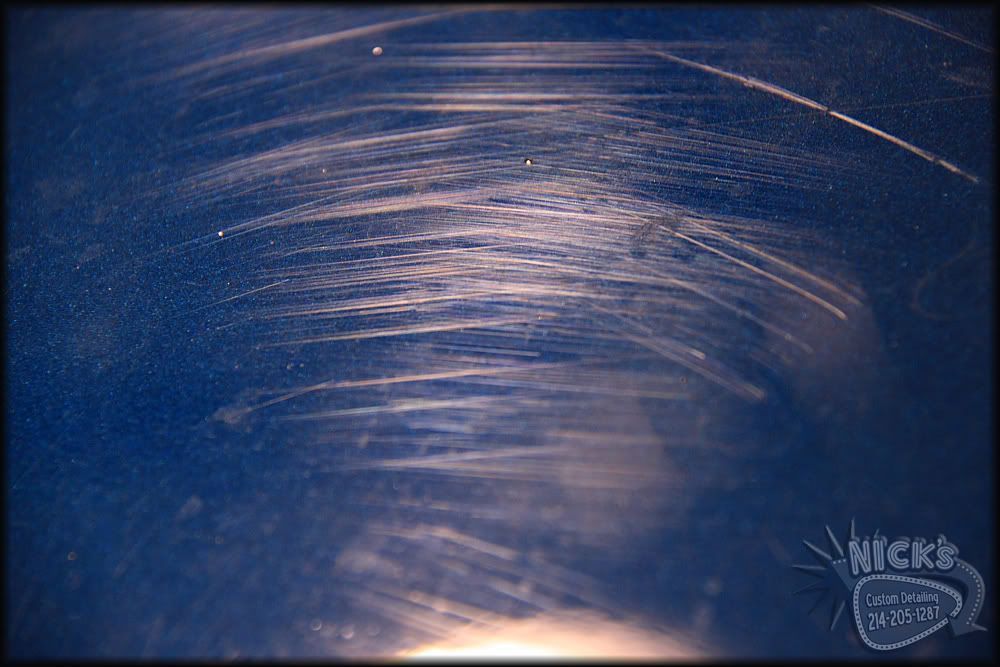

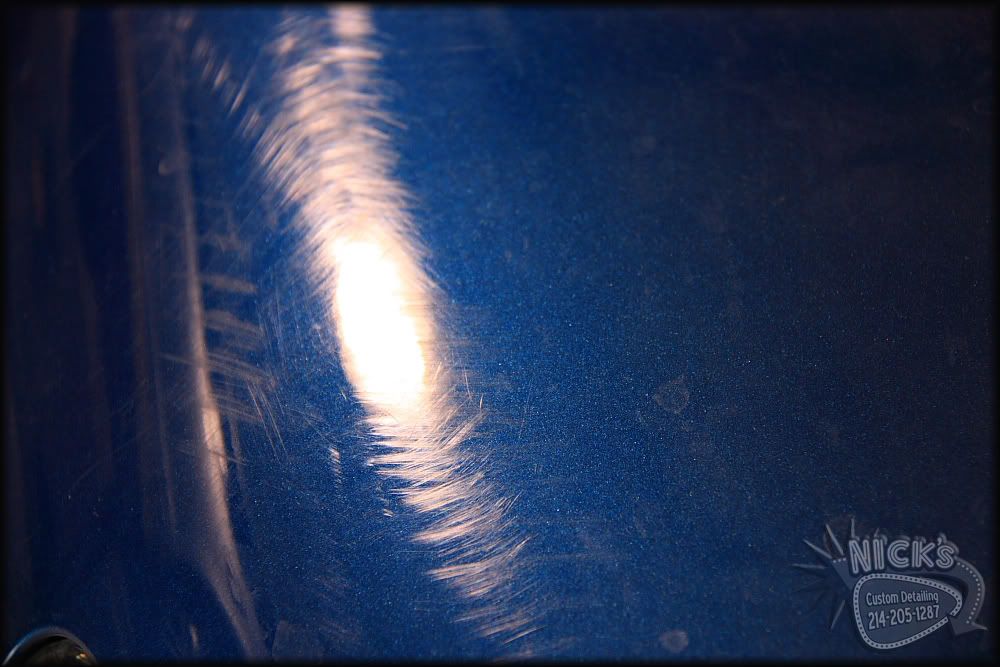

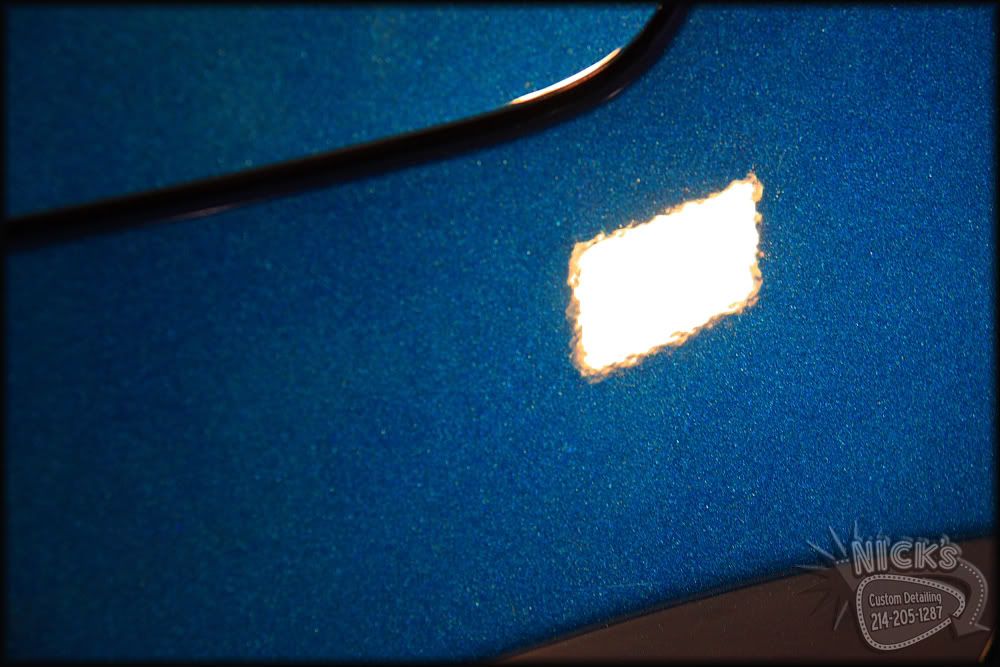

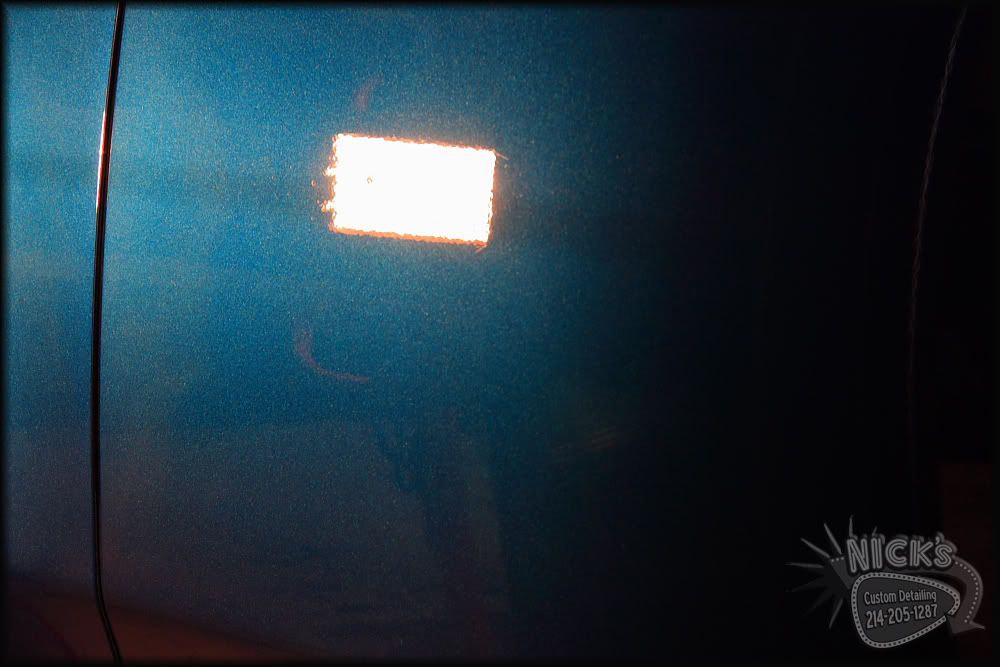

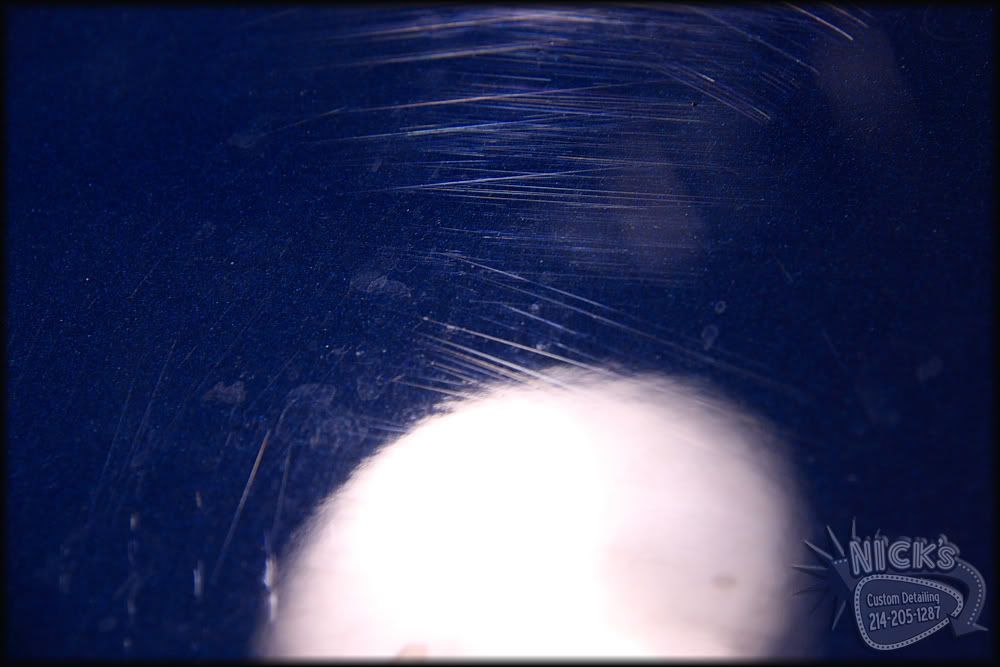

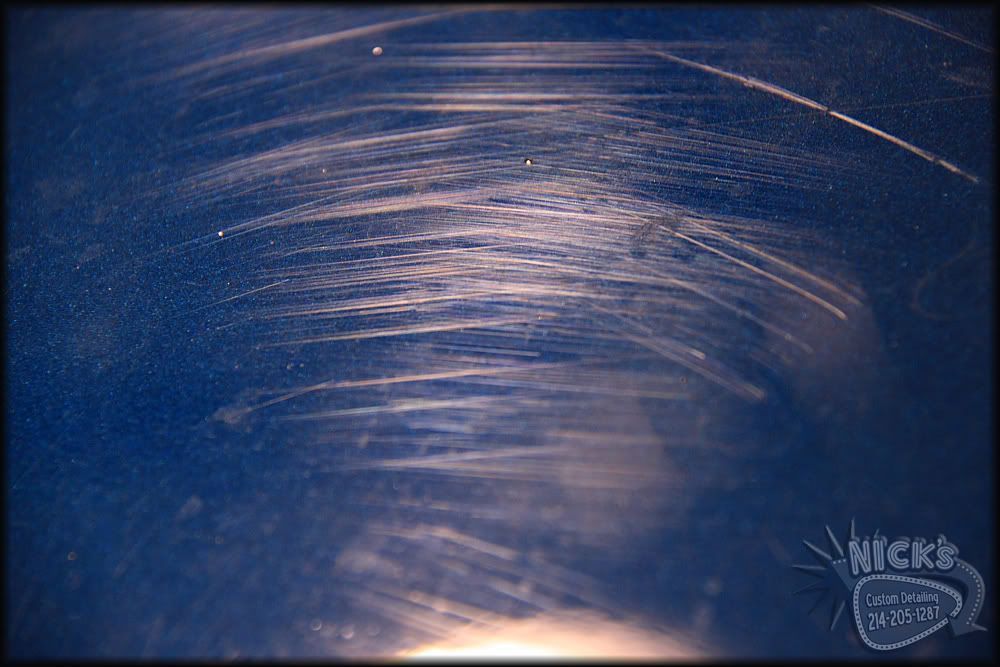

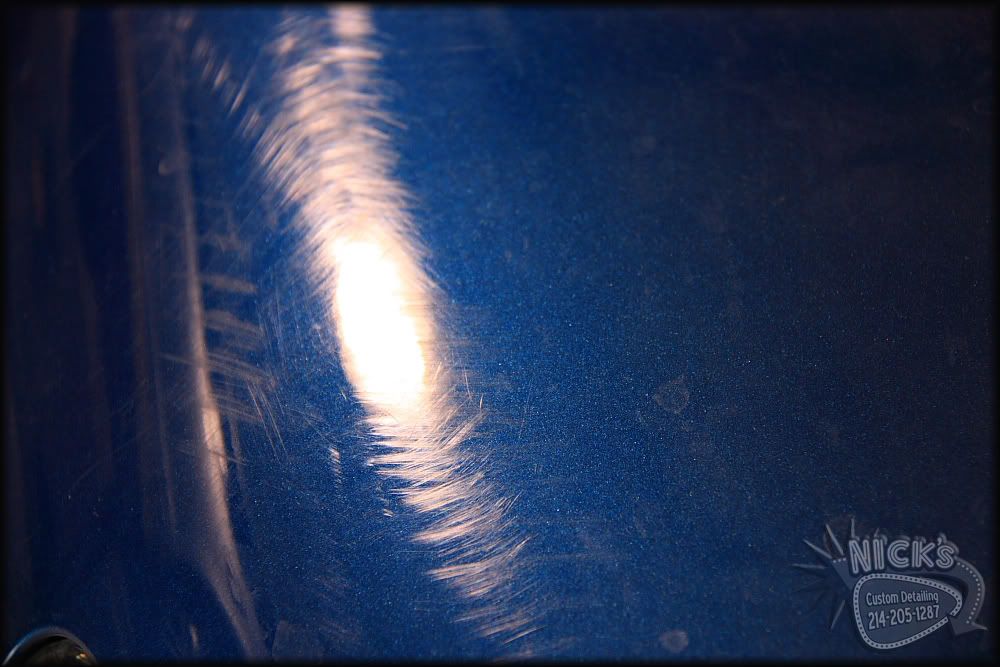

Befores:

Washed with Chemical Guys Citrus Based cleaner to strip everything away. Then clayed with Meguiar’s medium cut clay. Then corrected with Meguiar’s G110v2 and a 5” Microfiber Pad and M105, then straight to wax. Had some Rejex that I’ve had for a while, never used it so I thought I’d throw it on this beater

Total time on this car was 13 hours, interior and exterior

Befores: