My troubles and questions stem from the marketing aspects of the new DAs.

Probably no fix for this as you can't change how all the companies in the word operate. Your questions are good but still, you can't change the historical way 99.95 of all companies market their products.

Everyone says their stuff is the best. That's normal. Who would put out a product onto the market and advertise it's not very good?

The claims they make that you can get perfection, don't need skilled detailers anymore and can do perfect paint correction in shorter times with no risk.

My guess is that's a way of reaching out to new people that may have fears about machine polishing.

Point of fact - I reach out to new people every day and let them know that even though they are BRAND NEW to machine polishing, they can get professional results their very first time. Been saying this for years now.

Why?

Mostly due to three things,

1: Abrasive technology - It's so good you don't have to be good to get good results.

2: Tools - Used to be all we had was the rotary buffer and

IN THAT TIME PERIOD all we had was crappy abrasive technology and wool pads - so "yes" you actually had to have some skill and experience to get good results. Great results did not come along until the foam pad was invented in 1965 by Walter Cotton.

3: Pad technology - Again... used to be just one pad option. Then later all that was available was

HUGE diameter pads and

THICK pads. That's all changed now. Who would have though 50, 40, 30, 20 and even 10 years ago we would have

1" pads?

This is why I always type/say I'm a

perpetual student. There's

NO WAY anyone can be an expert. There's simply too much new technology being introduced at break-neck speed that the only way one can hope and try, (that's two things), to stay caught up is to hang out on a forum like this.

Last year I wrote approximately 109 new articles. Here's a screenshot of the forum groups that show this...

Out of the 109 articles, the two I shared the most were these two,

Here's what you need to get into machine polishing - Recommendations for a beginner by Mike Phillips

How, why & when to inspect your microfiber towels when detailing cars

The first article was written specifically to reach out to

NEW PEOPLE that want to make the leap from working by hand to working by machine. Taking normal things like fear and apprehensiveness into consideration plus a person's willingness to break open the bank to get started, I recommended the Griot's Garage 6" Random Orbital Polisher. The

BIG PICTURE is that with this tool and MODERN

abrasive technology and quality pads anyone that can focus their brand and has enough muscle to grip the tool and guide it in an overlapping crosshatch patter can get professional result their very first time.

And the Lord knows myself and many others have posted horror stories over and over again on this forum sharing where a car was destroyed by a hack detailer (supposed to be "Pro"), or by taking their car to a dealership and having the dealership's staff wash or detail their car, (supposed to be pros), and if that is the criteria then I'd put my money on any newbie, buying the Griot's 6" ROP and then coming here to get start-up guidance any day of the week.

If fact, back in 2012, 6 years ago I wrote this article and it's the

PICTURES that tell the story...

Machine polishing paint - It's not that hard and with modern dual action polishers it's real safe!

I just don't agree with all of that and to me sounds gimmicky,

I think there's a valid point that can and is being made that "yes" a brand new person using quality tools, abrasive technology and pads can in fact get professional result their very first time and without using a rotary buffer in most cases.

I'll go on record as saying the below and note that as a veteran of the

NXT vs Zaino Wax Wars I am very good at picking and choosing each and every single word I use on this forum and in the sentence below.

"The use of the rotary buffer is the fastest way to remove defects, (remove paint) no matter what the shape of the panel and from paint that is close to edges and or objects"

And the reason I included the last portion in that sentence about buffing near objects is because with any free spinning orbital and to a lesser degree with gear driven orbital polishers, it's more difficult to apply cutting ability to the outer edge of the pad because when the pad is oscillating only a portion of the pad is in contact with the paint near the object AND when the spinning pad comes into contact with the edge of the object the friction between the pad and the object will slow or stall pad rotation for free spinning tools. I think the 5mm gear driven orbitals like the Makita PO500C and the RUPES Mille are able to do correction work to the paint next to an object and an edge or raised body line (and for sure curved panels), but overall the rotary buffer still trumps all other tool options simply due to the single direction rotating action and the ability to buff right up to the surface of a protruding object (affixed to a body panel), without pad stall. Plus there are small pad options for rotary drive tools that also make the rotary tool action more effective.

The may be a lot to digest if you have not used most or all of the tools on the market of which I think it's safe to say I have, at least out of U.S. based options.

These pictures and the description from post #28 of my review here kind of show what I mean...

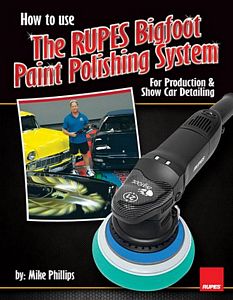

Review: RUPES BIGFOOT MILLE LK 900E by Mike Phillips

BTW, Mike.

Did you notice that because the Mille is more effective out on the edge you got a better result in tight places and didn't have to reach for a different machine on posts etc.?

RSW

Mike Phillips said:

Yes and I believe that is for two reasons working together.

it's the shorter stroke or orbit stroke length plus the gear-driven aspect that makes it easier to do correction near edges.

With a long stroke free spinning tool, as the outer edge of a pad hits anything it tends to cause the pad to stall out.

In my RUPES how-to book

On page 55, I created a term called,

The Ghosting footprint and the actual footprint

Here's page 54 and 55

Down just to the right of my thumb is this section...

When you look down at a 21mm, 15mm or 12mm long stroke orbital polisher - if you look carefully you'll see two perimeters... the outer perimeter is the ghosting footprint as there is not 100% pad contact 100% of the time. The inner perimeter is the actual footprint and there is 100% of pad contact 100% of the time.

I'm not very good in PS so here's the best I could do using the images already in the book.

(It's powerful to know how to work with pictures, write and then remember where all this stuff is at

)

lowers the perceived standard of a professional and lowers the prices detailers can charge for paint correction.

Hack work lowers the standard for quality for our industry as well as the image and perception of our industry.

Getting a high or fair price for you work comes down to,

A: Your own skill, ability and experience

B: Educating your customer and differentiating yourself from the hacks that work for subpar prices in our industry.

I teach both of the above in all my 3-day classes here at Autogeek.