Mike Phillips

Active member

- Dec 5, 2022

- 51,004

- 8

Mike Phillips - hi Mike, did you experience the same poor pad rotation in free spin mode during your initial review?

Thanks,

ScottH

Yes. I found it difficult to maintain pad rotation in the free-spin mode. I've only buffed out the 1971 Duster with this tool and that's all I've had time for as we've had a lot of video projects in the garage in the last two weeks and more this week.

Here's what used this tool for on the Duster and the mode and the order I did the processes

Machine sanding with Mirka Abralon #3000 = Gear driven mode

Machine sanding with Mirka Abralon #4000 = Free spin mode

Machine sanding with Mirka Abralon #4000 = Free spin mode

Comment: You shouldn't sand with the Makita PO5000C in the gear driven mode because it's too aggressive. I broke the rule because I felt lucky. I explain why you shouldn't use the Makita PO5000C to machine sand in the gear driven mode in my article on this topic with the FLEX 3401 here - dated February 14th, 2013

Can the Flex 3401 be used to wetsand?

I coined the term scalloping after the experience and strongly recommend against using a FLEX 3401 to machine sand clearcoat paints. I

In my boat detailing how-to book I do recommend using the FLEX 3401 for machine sanding gel-coats and aluminum but that's because these two materials are MUCH THICKER than clearcoat paints and they degrade to much worse condition. See the sections on restoring boats in category #4 and restoring aluminum pontoon boats.

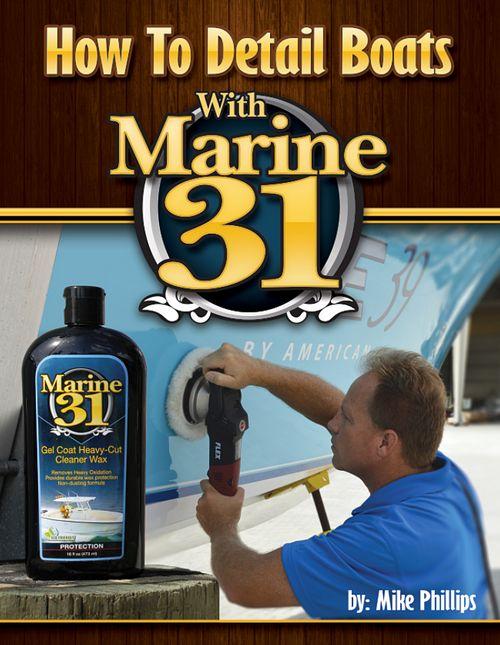

Paperback book - How To Detail Boats With Marine 31 by Mike Phillips

Continued....

Here's what used this tool for on the Duster and the mode

Machine compounding to remove the #4000 grit sanding marks - Gear Driven Mode

Machine polishing to refine the results from the compounding step - Gear Driven Mode

Machine waxing to seal the paint after sanding, compounding and polishing = Free Spin Mode

Machine polishing to refine the results from the compounding step - Gear Driven Mode

Machine waxing to seal the paint after sanding, compounding and polishing = Free Spin Mode

I tested a lot of pads as shown in my initial review in the gear-driven mode and found that the Makita PO5000C will turn and churn just about any 5.5" foam or microfiber pads. I did not test larger pads in the gear driven mode. For the free spinning mode all I tested was the 5.5" Lake Country CCS pads and I did have difficulty maintaining pad rotation. This is why I did the compounding and polishing steps in gear-driven mode and used the free spinning mode to machine apply the wax as you don't need pad rotation to machine apply a wax.

I'll need to spend some more time behind the tool to find out more about it's abilities and limitations as well as test out other pad options to see which pad types work best and which don't.